A kind of preparation method of C-doped multi-core mgb2 superconducting wire prepared by solution coating method

A technology of superconducting wires and solutions, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems of reduced performance, increased cost, abnormal growth of grains, etc., to avoid The effect of reducing superconducting performance, meeting application requirements, and improving magnetic flux pinning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

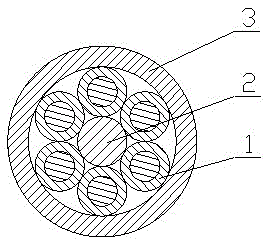

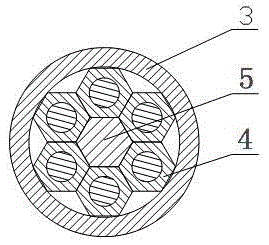

[0029]Step 1: First, amorphous boron powder (more than 99% of purity), -325 mesh spherical magnesium powder (99.8% of purity) is batched according to the atomic number ratio of Mg:B=0.95:2, after mixing evenly, pour into pre-configured In the oxalic acid ethanol solution, the amount of oxalic acid in the solution is 15% of the mass of the mixed powder of Mg and B, and the mass concentration of the oxalic acid solution is 15%. Stir the mixed suspension in a 200 R / min magnetic stirrer for 60 minutes, then heat the suspension while magnetically stirring, and control the temperature at 55°C until the viscosity of the suspension increases significantly, causing the magnetic stirring to When the stirrer cannot be stirred, pour the mixed slurry into a petri dish, put it into a vacuum oven and dry it at 50°C, grind the dried powder, put it into a burning boat, and carry out low-temperature decomposition treatment in a tube furnace, with 0.5 The heating rate of ℃ / min is up to 150 ℃, th...

Embodiment 2

[0036] Step 1: First, amorphous boron powder (more than 99% of purity), -325 mesh spherical magnesium powder (99.8% of purity) is batched according to the atomic number ratio of Mg:B=0.95:2, after mixing evenly, pour into pre-configured In the oxalic acid ethanol solution, the amount of oxalic acid in the solution is 30% of the mass of the mixed powder of Mg and B, and the mass concentration of the oxalic acid solution is 20%. Stir the mixed suspension in a 300 R / min magnetic stirrer for 30 minutes, then heat the suspension while magnetically stirring, and control the temperature at 65°C until the viscosity of the suspension increases significantly, causing the magnetic stirring to When the device cannot be stirred, pour the mixed slurry into a petri dish, put it into a vacuum oven for drying at 60°C, grind the dried powder, put it into a burning boat, and carry out low-temperature decomposition treatment in a tube furnace. The heating rate of ℃ / min is up to 200 ℃, and the tem...

Embodiment 3

[0043] Step 1: First, amorphous boron powder (more than 99% of purity), -325 mesh spherical magnesium powder (99.8% of purity) is batched according to the atomic number ratio of Mg:B=0.95:2, after mixing evenly, pour into pre-configured In the oxalic acid ethanol solution, the amount of oxalic acid in the solution is 20% of the mass of the mixed powder of Mg and B, and the mass concentration of the oxalic acid solution is 18%. Stir the mixed suspension in a 250 R / min magnetic stirrer for 45 minutes, then heat the suspension while magnetically stirring, and control the temperature at 60°C until the viscosity of the suspension increases significantly, causing the magnetic stirring to When the device cannot be stirred, pour the mixed slurry into a petri dish, put it into a vacuum oven for drying at 55°C, grind the dried powder, put it into a burning boat, and carry out low-temperature decomposition treatment in a tube furnace. The heating rate of ℃ / min is up to 180 ℃, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com