Cross-road cable laying structure and construction method thereof

A cable laying and construction method technology, applied to overhead lines/cable equipment, cable suspension devices, etc., can solve the problems of time-consuming and labor-intensive, cable slump, unstable cable installation structure, etc., to reduce looseness and shedding, and improve construction. Efficiency, clean and controllable installation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

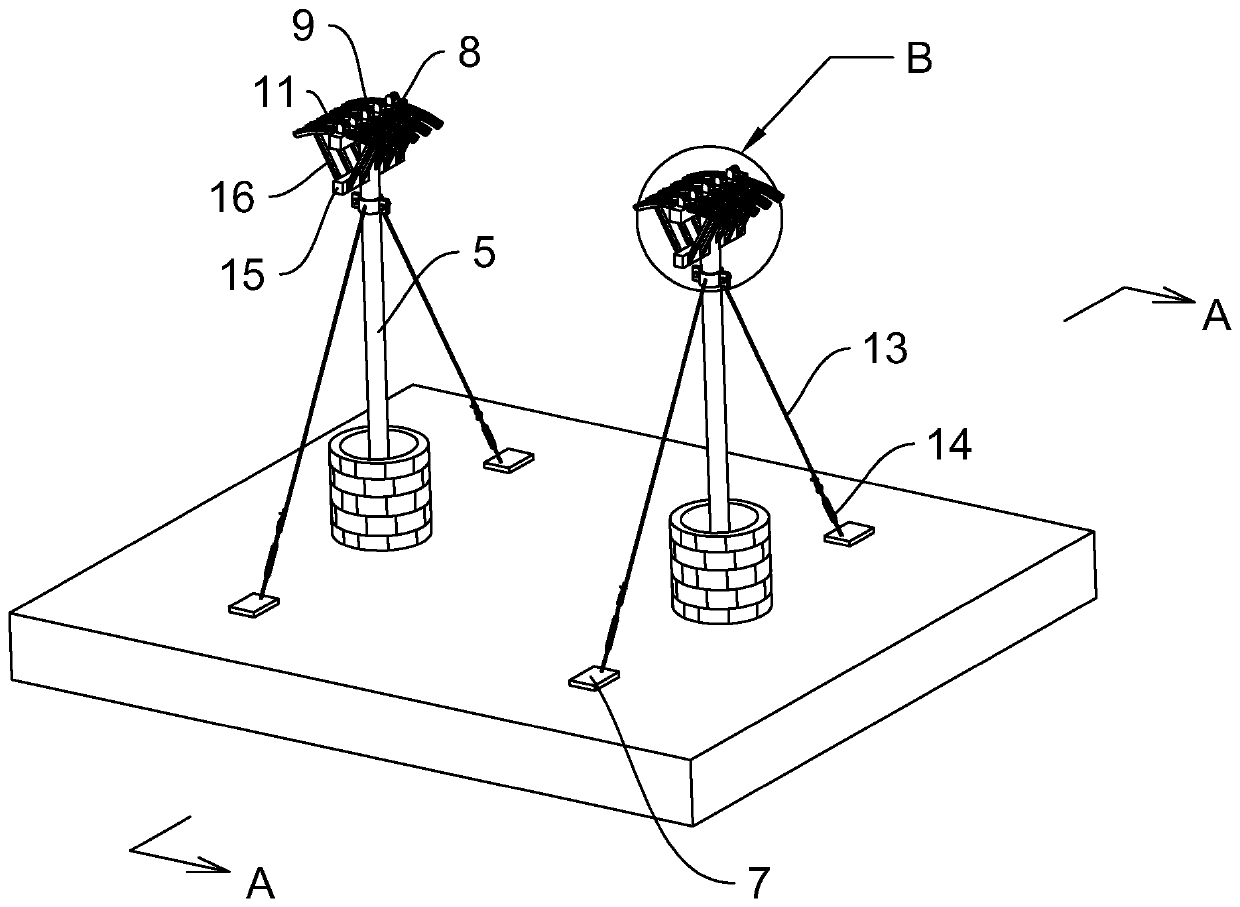

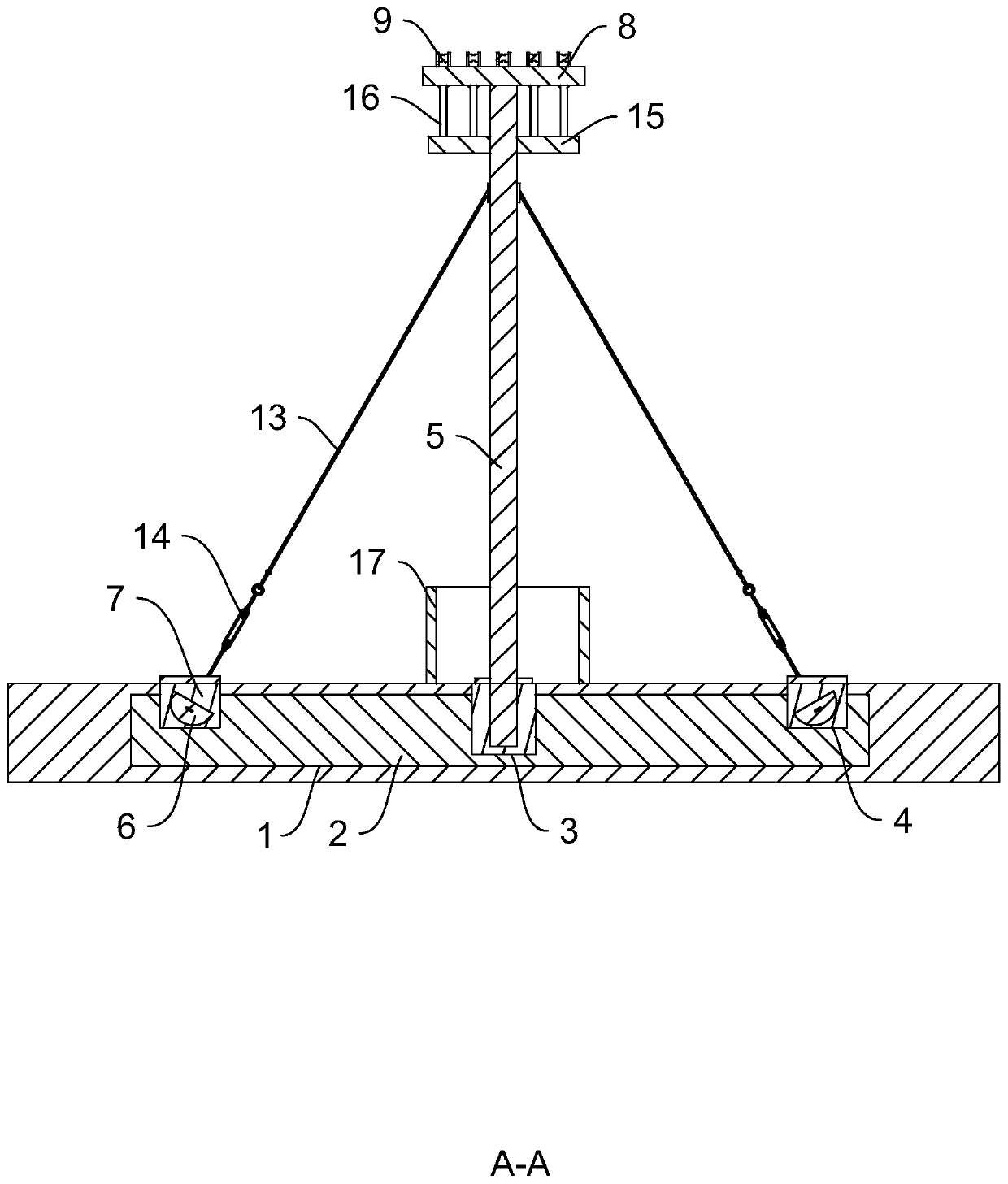

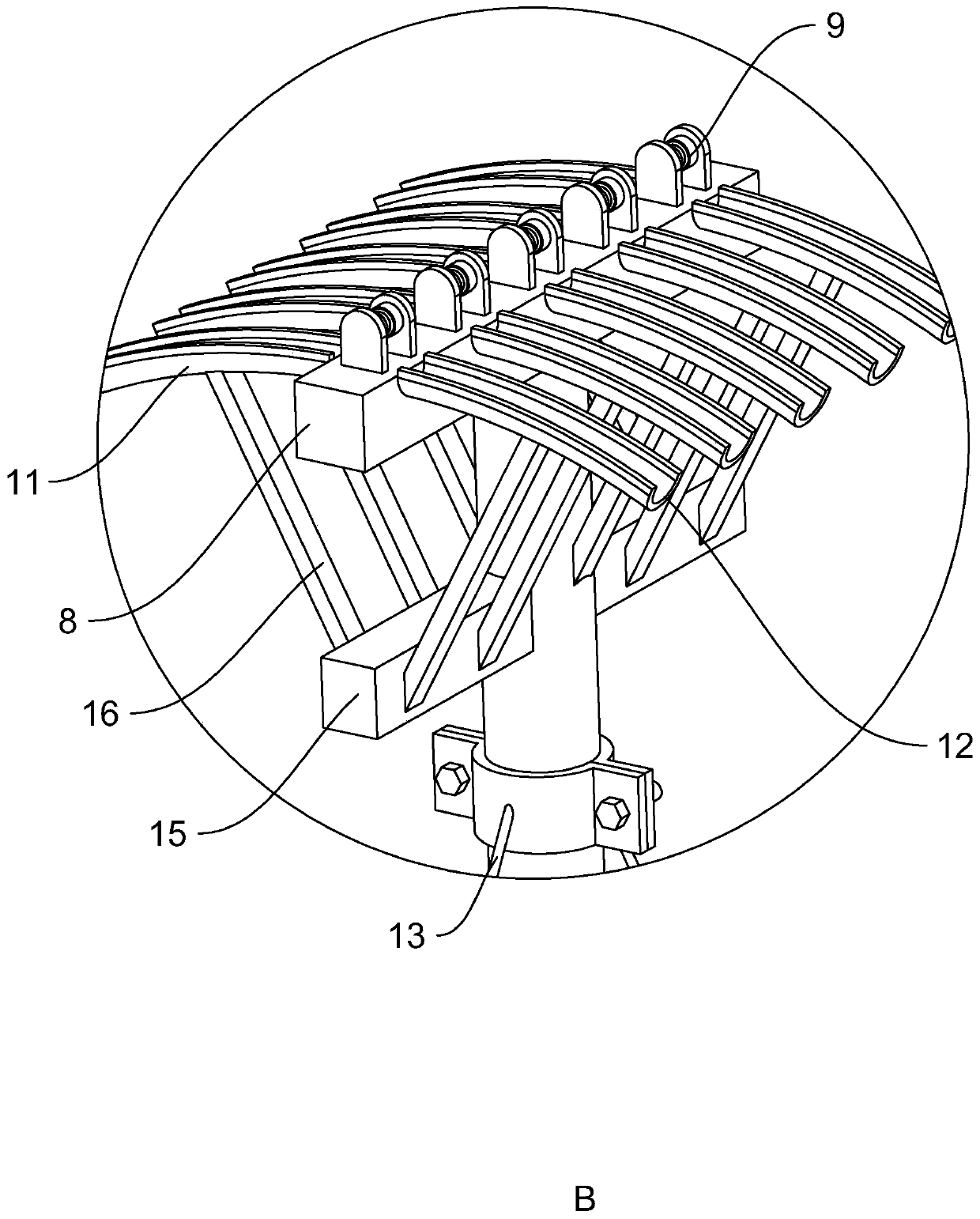

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0047] refer to figure 1 and figure 2 , is a cross-road cable laying structure disclosed by the present invention, including pre-embedded pits 1 respectively opened in the soil on both sides of the road, pre-embedded bases 2 are pre-embedded in the pre-embedded pits 1, and the pre-embedded bases 2 are made of concrete Prefabricated with steel bars, the depth of the pre-embedded pit 1 is greater than the height of the pre-embedded base 2, and the sides of the pre-embedded base 2 are filled with soil layers. The prefabricated pre-embedded base 2 is used as the base to form a stable support connection structure in the soil body, which is easy to produce, environmentally friendly, convenient to construct, and low in cost.

[0048]The pre-embedded base 2 is provided with a pole installation pit 3 and a pull plate installation pit 4, a cable pole 5 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com