Motor core riveting device

A technology of iron core and frame, which is applied in the field of riveting devices, and can solve the problems of cumbersome and time-consuming operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

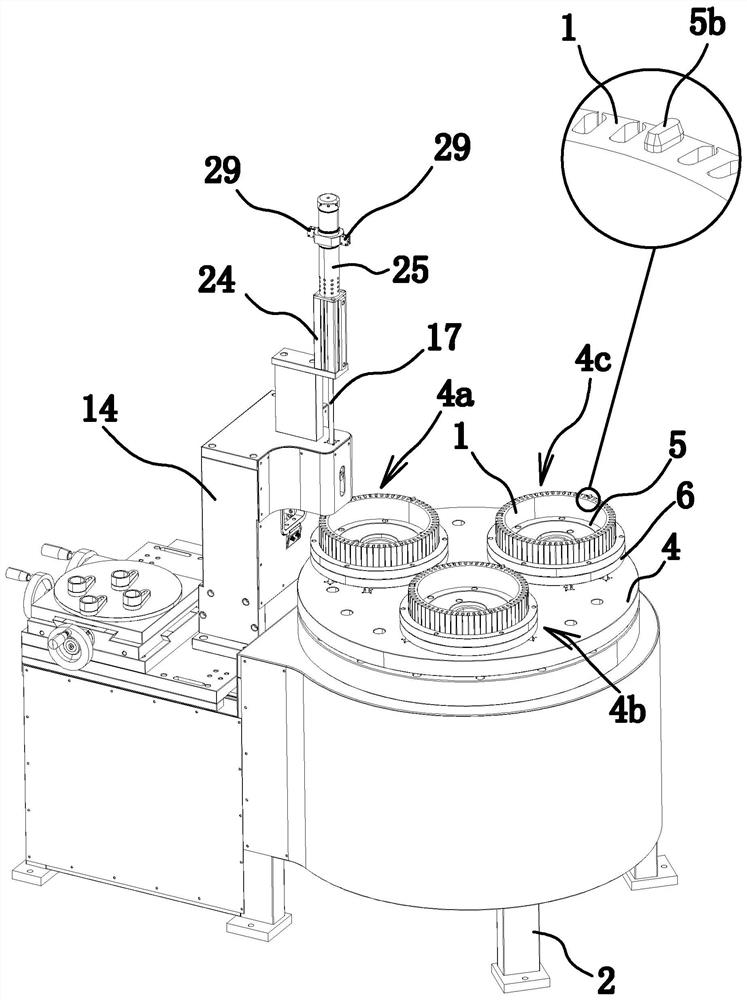

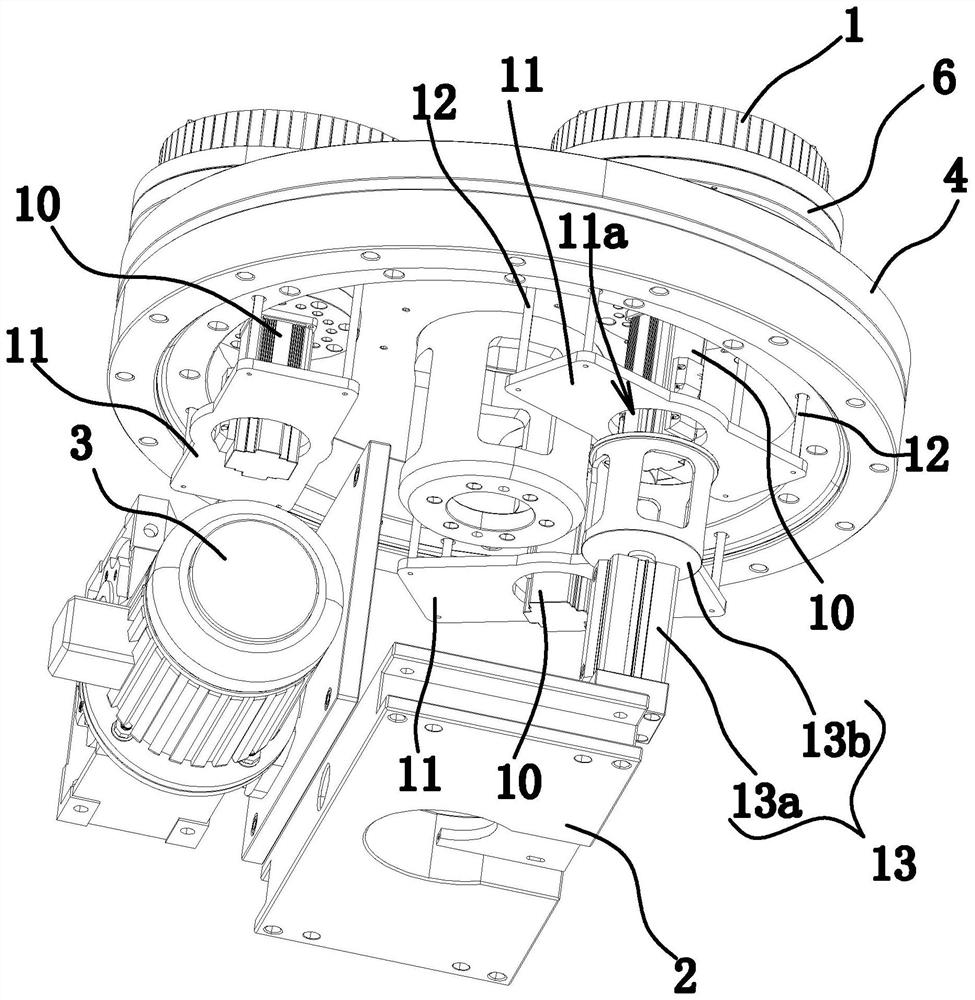

[0056] Such as figure 1 As shown, the motor iron core riveting device is generally composed of a conveying mechanism for conveying the iron core 1 and a pressing mechanism for pressing the rivets 37 into the iron core 1 .

[0057] in,

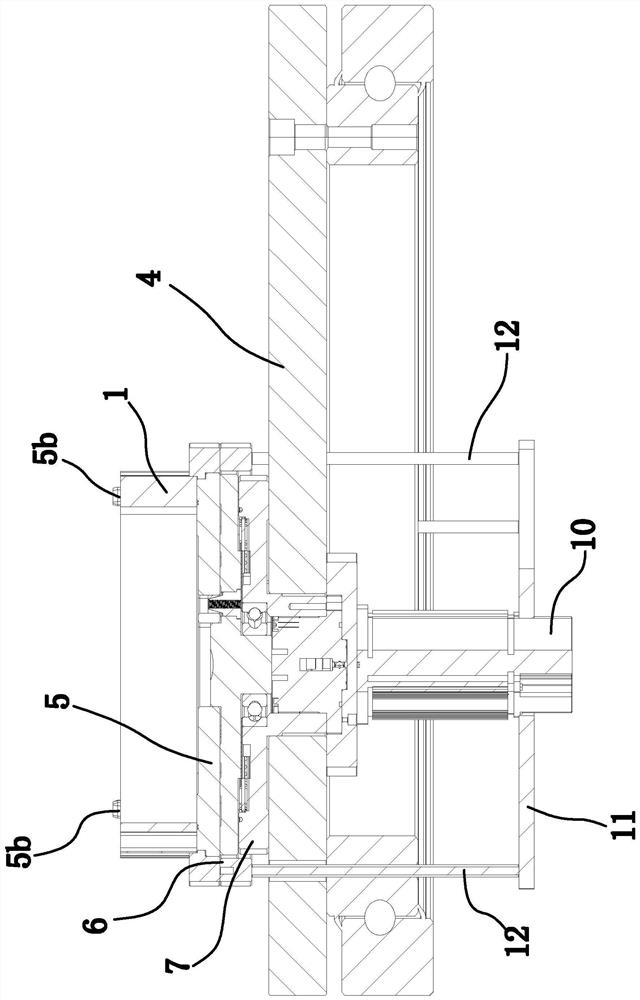

[0058] The conveying mechanism includes a driving mechanism, a frame 2, a motor one 3 fixed on the frame 2, and a turntable 4 horizontally arranged on the frame 2 and driven by the motor one 3 to rotate. A riveting station 4a, a feeding station 4b, and a discharging station 4c are evenly distributed on the turntable 4 in sequence, wherein a pressing mechanism for pressing the rivet 37 into the iron core 1 is provided on one side of the riveting station 4a. The riveting station 4a, the jacking station 4b and the discharging station 4c are all provided with a positioning die 5 that is rotatably connected with the turntable 4 . In this embodiment, the motor one 3 is connected with the turntable 4 through a cam divider, so that the turntable 4 ro...

Embodiment 2

[0081] The structure and principle of this second embodiment are basically the same as that of the first embodiment, except that the driving mechanism includes telescopic cylinders 2 and a connecting frame 32 in the shape of a "concave" that are all located on the lower side of the turntable 4, telescopic cylinders 2 and The quantity of connecting frame 32 is all the same with the top cover 6 and the positions correspond one by one.

Embodiment 3

[0083] The structure and principle of the third embodiment are basically the same as those of the first embodiment, except that the position-limiting structure includes the bottom wall of the top sleeve 6 and the top wall of the turntable 4, and the bottom wall of the top sleeve 6 presses against the top wall of the turntable 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com