Method and device for recycling pump washing water in floor construction

A floor and water pumping technology, which is applied in separation methods, chemical instruments and methods, and construction material processing, can solve problems such as many elevator shafts, difficult cleaning of concrete slag, and non-conforming to environmental protection and green construction, so as to reduce construction costs, Reduced construction water consumption and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

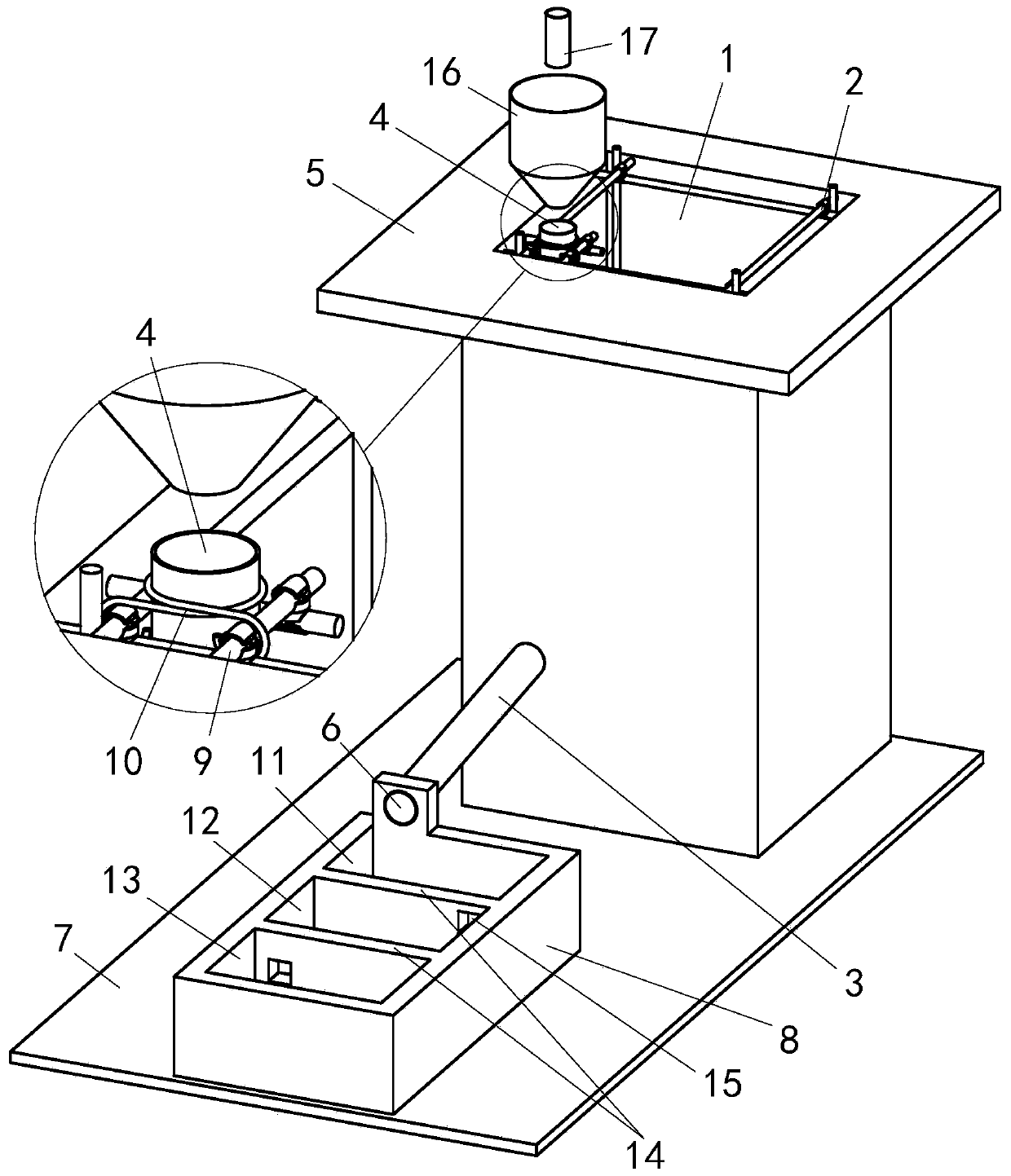

[0019] The implementation process of this example is as follows: first adopt the autoclaved aerated concrete blocks of 200 * 200 * 600mm to build a long 3.8 meters, a width of 2.0 meters, and a sedimentation tank 8 of 0.9 meters high on the ground 7 near the elevator shaft 1. Two partition walls 14 are built with autoclaved aerated concrete blocks in the sedimentation tank 8, and the sedimentation tank 8 is divided into a primary sedimentation tank 11, a secondary sedimentation tank 12 and a tertiary sedimentation tank 13 through the partition walls 14. An overflow hole 15 is left on each partition wall 14 . The two overflow holes 15 are arranged diagonally to increase the residence time of the sewage in the sedimentation tank 8, so that the sewage can be more fully settled. The surfaces of the sedimentation tank 8 and the partition wall 14 should be smoothed, and waterproof treatment should be done in the sedimentation tank 8 .

[0020] Then adopt steel pipe to set up steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com