Extrusion crusher with bionic crushing mechanism

A crushing mechanism and crushing machine technology, applied in grain processing, etc., can solve the problems of not conforming to the concept of environmental protection, excessive power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

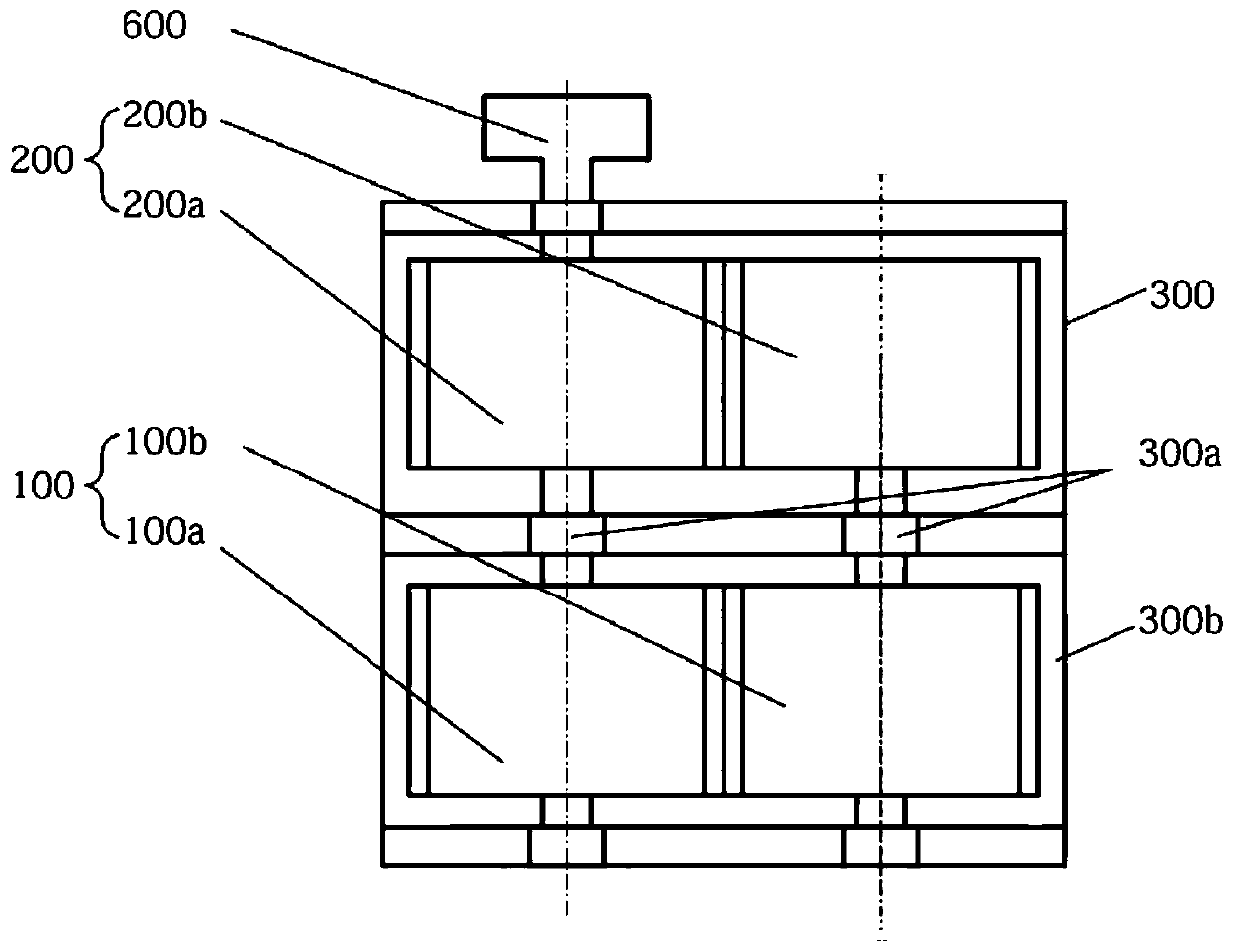

[0035] This embodiment provides a squeeze crusher with a bionic crushing mechanism. Such as figure 1 As shown, the extrusion crusher includes a bionic crushing mechanism 100 , a transmission mechanism 200 and a frame 300 .

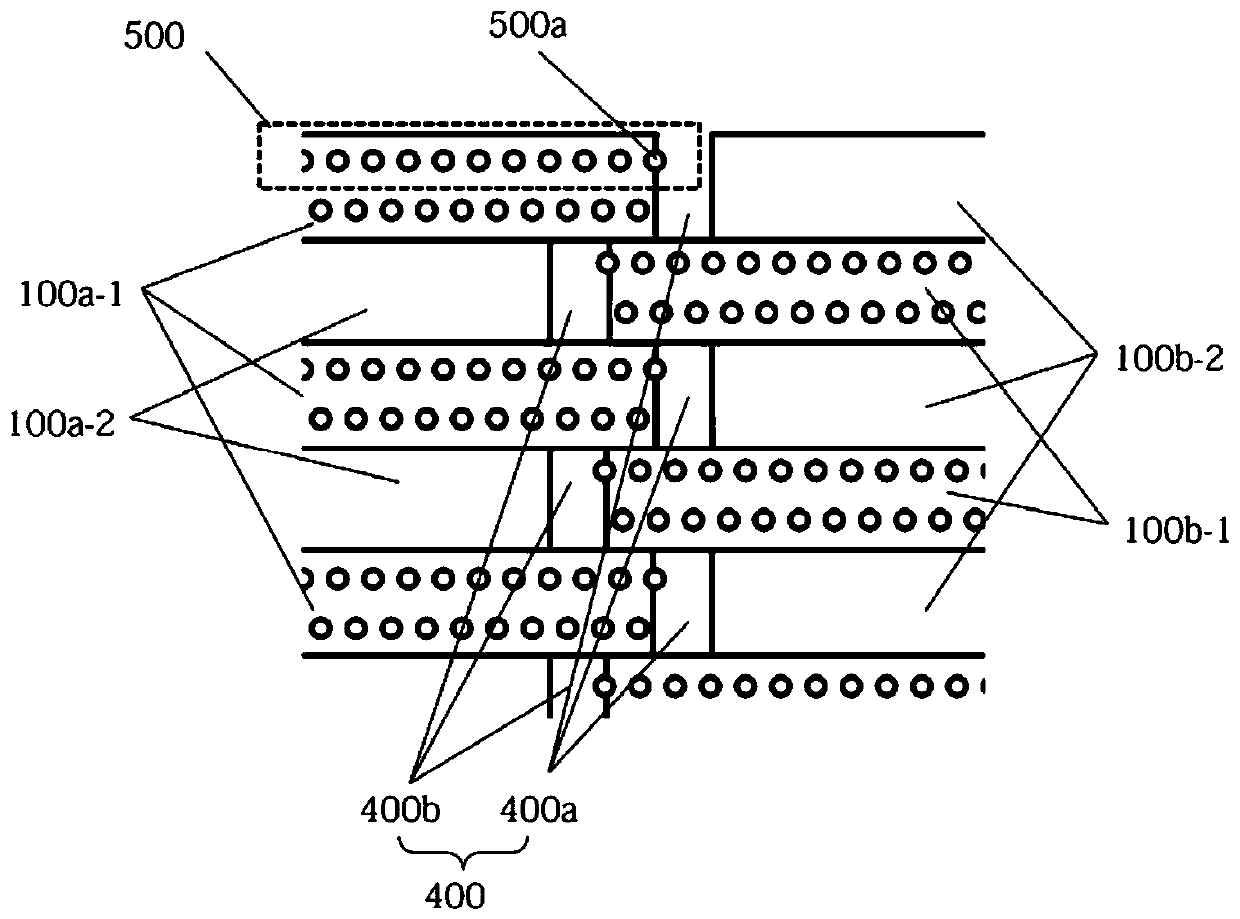

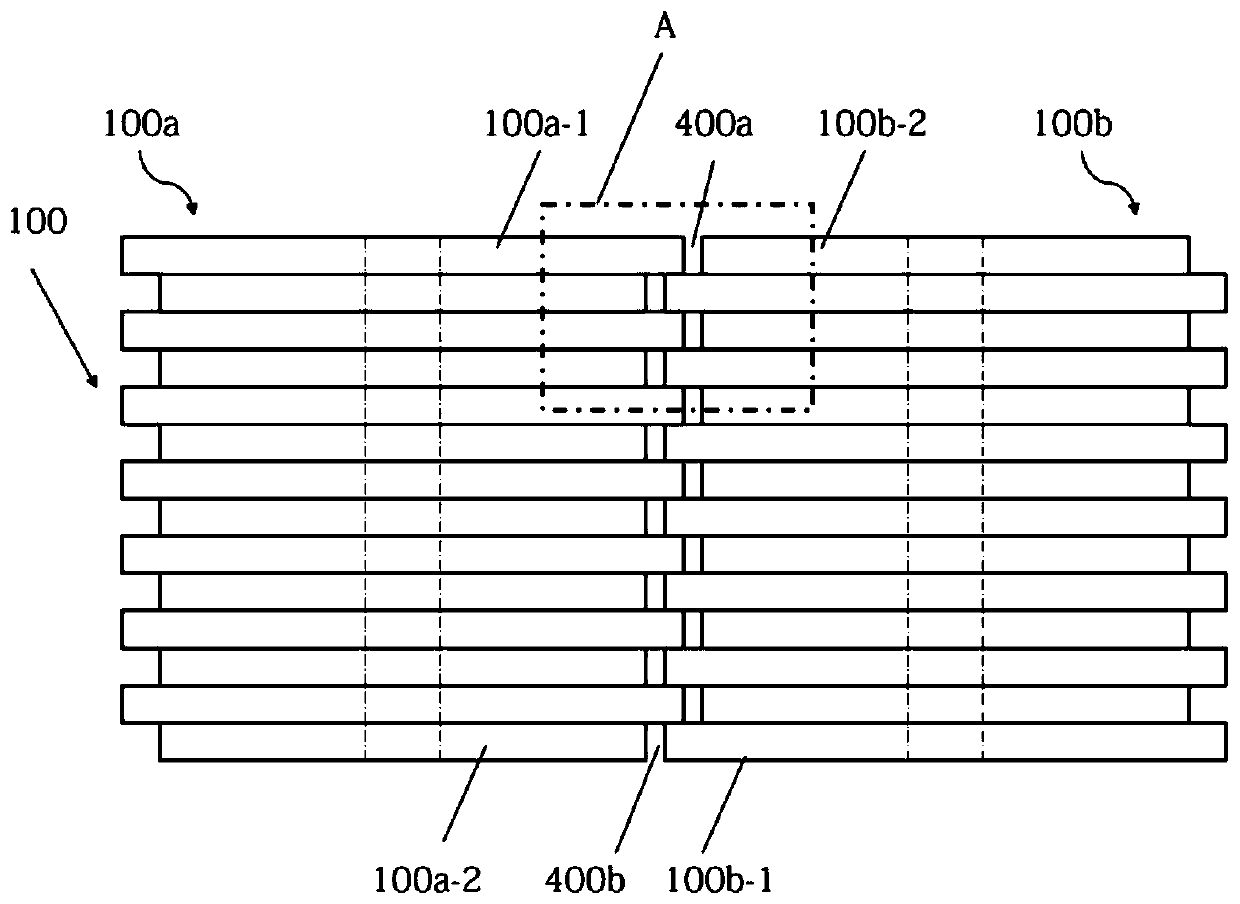

[0036] Such as figure 1 As shown, the bionic crushing mechanism 100 includes a first bionic roller 100a and a second bionic roller 100b. Such as figure 2 and 3 As shown, there is a crushing gap 400 between the first bionic roller 100a and the second bionic roller 100b.

[0037] Such as figure 1 As shown, the transmission mechanism 200 includes a primary transmission wheel 200a and a secondary transmission wheel 200b. The main transmission wheel 200a is driven by the motor 600, and the main transmission wheel 200a is connected with the first bionic roller 100a through a transmission shaft to drive the first bionic roller 100a. The main transmission wheel 200a and the secondary transmission wheel 200b mesh with each other, so that the main transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com