Power driving system and vehicle with same

A technology of power drive and power coupling, which is applied to hybrid vehicles, the layout of multiple prime movers of general power plants, motor vehicles, etc., can solve the problems of low transmission efficiency, insufficient rigidity and strength of gear gears, and long transmission chains. And other problems, to achieve the effect of ensuring smoothness, small length and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

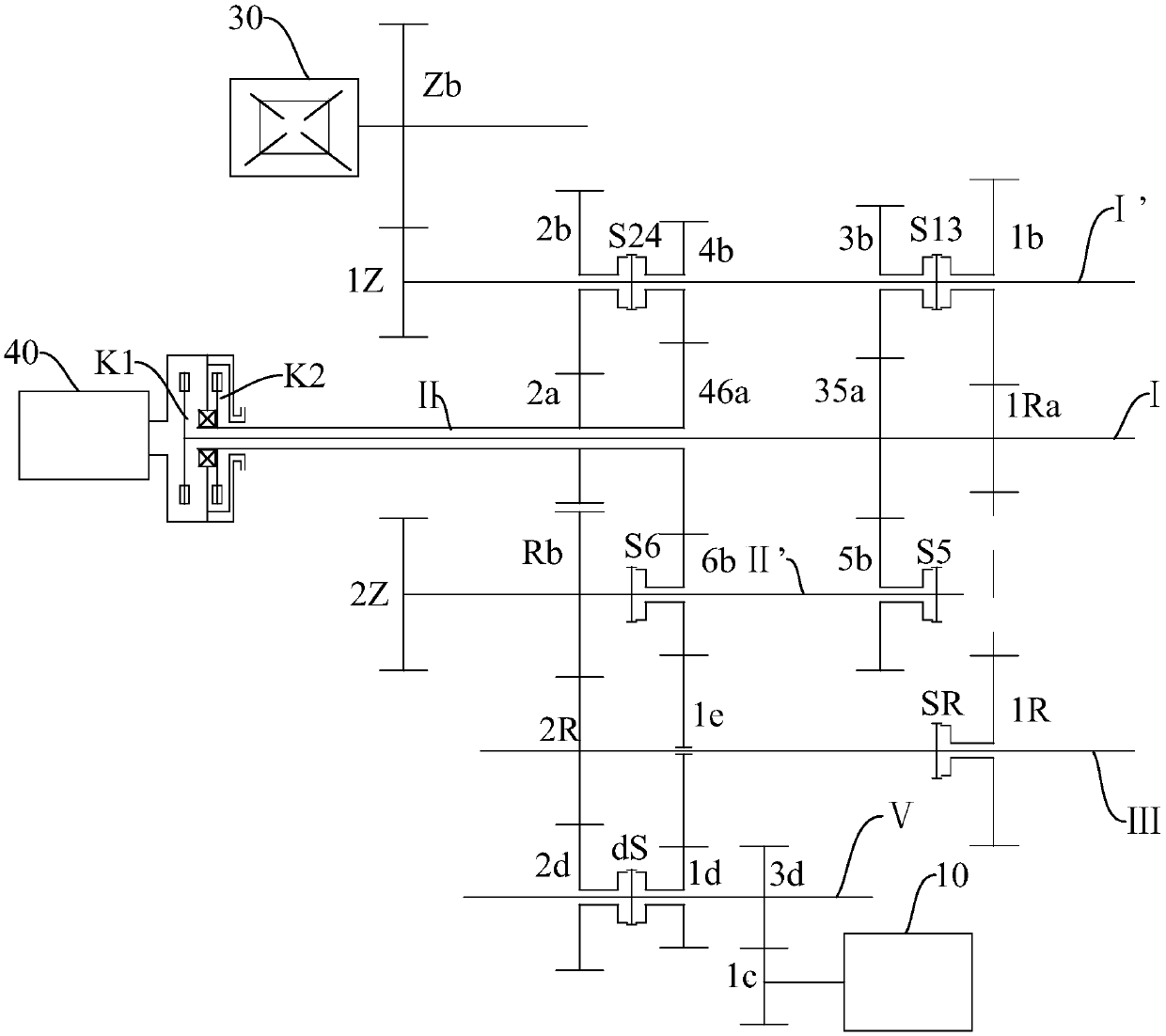

[0122] like figure 1 As shown, the main structure of the transmission can refer to the description of the above embodiment, the difference lies in the structure of the first transmission mechanism. Wherein, the first transmission mechanism includes: the first motor side gear 1c, the intermediate shaft V, the first intermediate shaft gear 1d, the second intermediate shaft gear 2d, the intermediate shaft side gear 3d, the first idler gear 1e, and the intermediate shaft side gear 3d It is fixedly connected to the intermediate shaft V, and the first intermediate shaft gear 1d and the second intermediate shaft gear 2d are loosely sleeved on the intermediate shaft V, the first motor side gear 1c is connected with the first motor generator, and is connected with the intermediate shaft side gear 3d Engagement, that is, the intermediate shaft V and the first motor generator 10 are connected through the meshing of the first motor side gear 1c and the intermediate shaft side gear 3d to r...

Embodiment 2

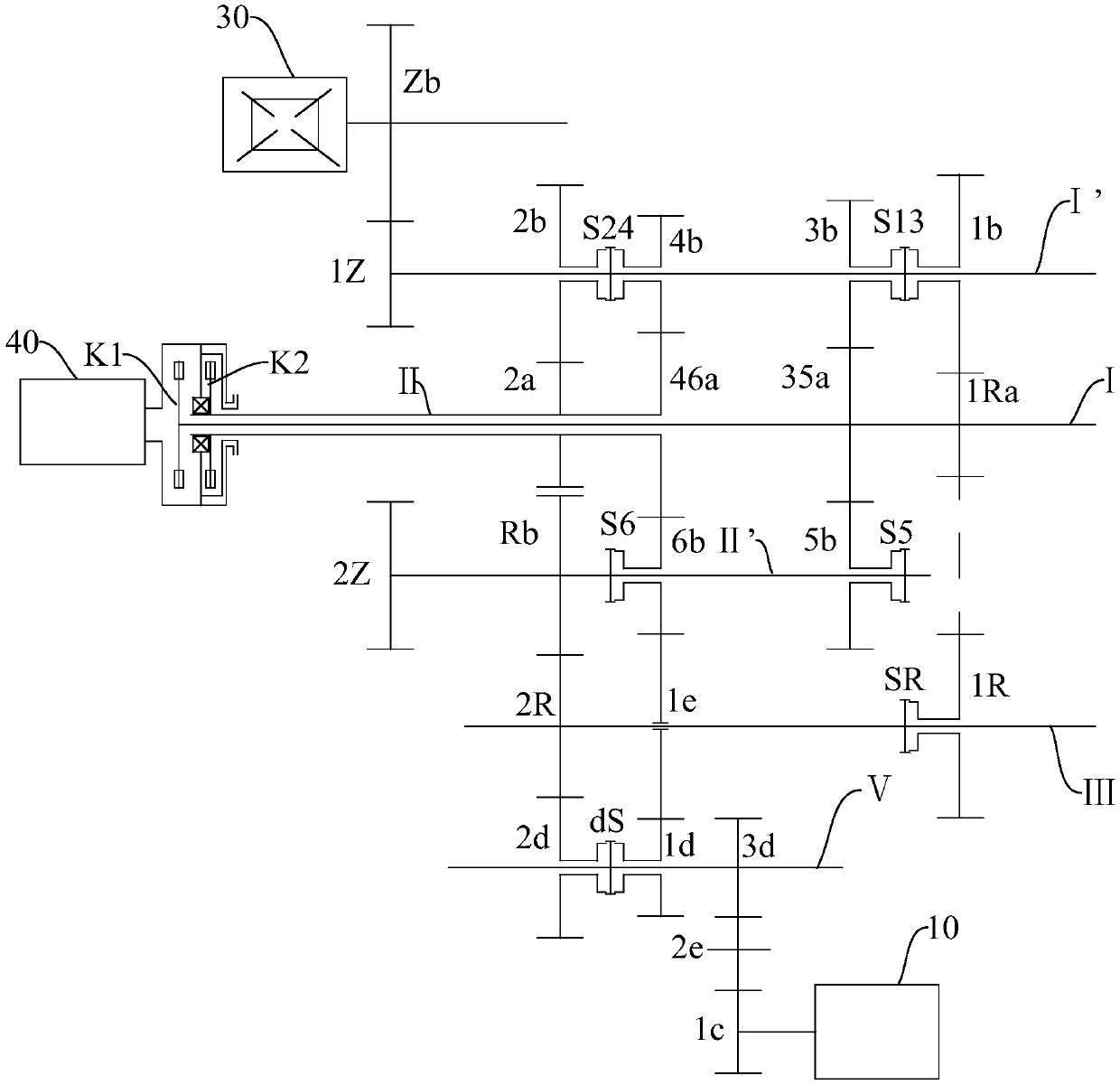

[0129] like figure 2 As shown, the main structure of the transmission can refer to the description of the first embodiment, the difference lies in the structure of the first transmission mechanism.

[0130] Wherein, the first transmission mechanism includes: the first motor side gear 1c, the intermediate shaft V, the first intermediate shaft gear 1d, the second intermediate shaft gear 2d, the intermediate shaft side gear 3d, the first idler gear 1e and the second idler gear 2e , the intermediate shaft side gear 3d is fixedly connected to the intermediate shaft V, and the first intermediate shaft gear 1d and the second intermediate shaft gear 2d are loosely sleeved on the intermediate shaft V, the first motor side gear 1c is connected with the first motor generator, and It meshes with the second idler gear 2e, and the second idler gear meshes with the intermediate shaft side gear 3d, that is, the intermediate shaft V and the first motor generator 10 pass through the first moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com