Great bright polyester fiber, spinneret plate for great bright polyester fiber spinning and preparation method of great bright polyester fiber

A technology of bright polyester and spinneret, which is applied in the field of chemical fiber materials, can solve the problems that the characteristic effect cannot be well highlighted, the mixing uniformity is not easy to control, and the production cost rises, etc., to achieve good smoothness and antistatic performance Strong, high oil film strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

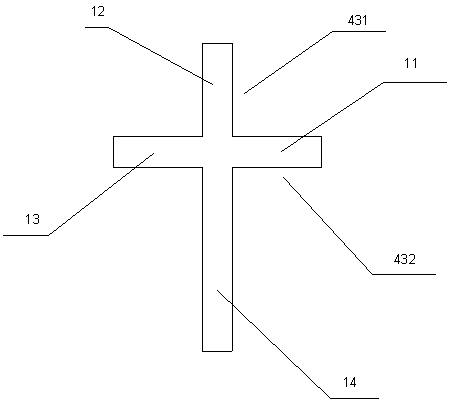

[0039] The cross-section of the described bright polyester fiber is different cross, the cross-section of the bright polyester fiber of different cross is different cross, and the cross-section of described different cross is composed of blade a, blade b, blade c and blade d, the length of the blade a, blade b and blade c is equal, the length of the blade d is twice the length of the other three blades, the blade a, blade b and blade c The length is 0.51 mm, and the length of the blade d is 1.02 mm.

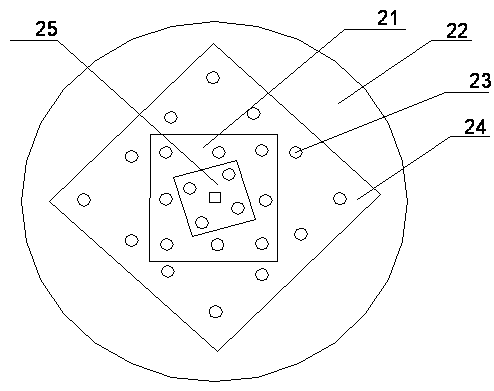

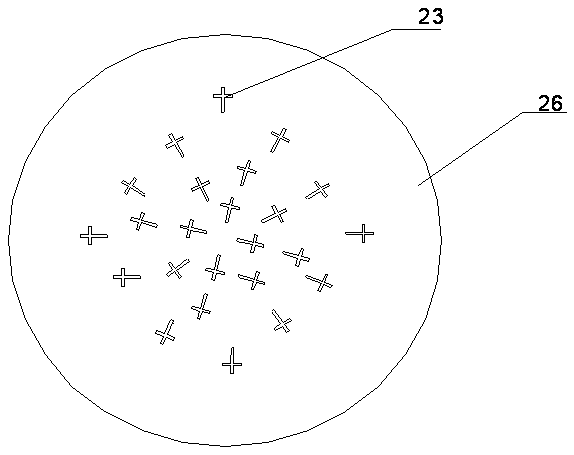

[0040] There are three diversion grooves and several spinneret mechanisms on the spinneret used for spinning large bright polyester fibers, and several spinneret mechanisms are evenly distributed on each diversion groove, and the three diversion grooves are The axes of the grooves are concentric, and each of the spinneret mechanisms is composed of an extrusion chamber, a transition chamber and a spinneret hole, and the transition chamber is connected to the extrusion chamber and ...

Embodiment 2

[0052] The cross-section of the described bright polyester fiber is different cross, the cross-section of the bright polyester fiber of different cross is different cross, and the cross-section of described different cross is composed of blade a, blade b, blade c and blade d, the length of the blade a, blade b and blade c is equal, the length of the blade d is twice the length of the other three blades, the blade a, blade b and blade c The length is 0.51 mm, and the length of the blade d is 1.02 mm.

[0053] There are three diversion grooves and several spinneret mechanisms on the spinneret used for spinning large bright polyester fibers, and several spinneret mechanisms are evenly distributed on each diversion groove, and the three diversion grooves are The axes of the grooves are concentric, and each of the spinneret mechanisms is composed of an extrusion chamber, a transition chamber and a spinneret hole, and the transition chamber is connected to the extrusion chamber and ...

Embodiment 3

[0065] The cross-section of the described bright polyester fiber is different cross, the cross-section of the bright polyester fiber of different cross is different cross, and the cross-section of described different cross is composed of blade a, blade b, blade c and blade d, the length of the blade a, blade b and blade c is equal, the length of the blade d is twice the length of the other three blades, the blade a, blade b and blade c The length is 0.51 mm, and the length of the blade d is 1.02 mm.

[0066] There are three diversion grooves and several spinneret mechanisms on the spinneret used for spinning large bright polyester fibers, and several spinneret mechanisms are evenly distributed on each diversion groove, and the three diversion grooves are The axes of the grooves are concentric, and each of the spinneret mechanisms is composed of an extrusion chamber, a transition chamber and a spinneret hole, and the transition chamber is connected to the extrusion chamber and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com