Rapidly-formed expansion steel pipe pile and construction method thereof

A technology of steel pipe piles and outer steel pipes, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of cumbersome construction technology, long pile-forming period, vibration, noise, pollution, etc., and achieve simple construction equipment and environmental protection The effect of less pollution and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

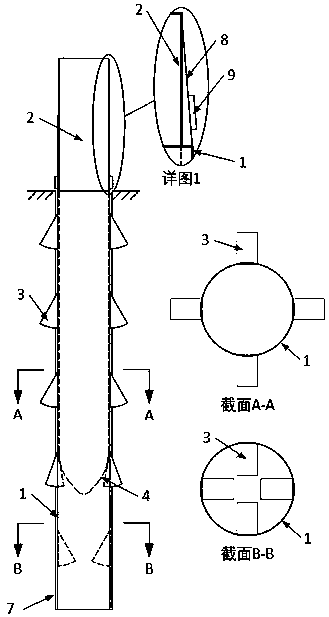

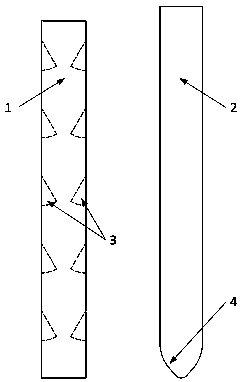

[0031] A kind of rapid expansion steel pipe pile, such as figure 1 As shown, including outer steel pipe 1 and inner steel pipe 2; figure 2 As shown, a number of expansion anchor claws 3 are installed at different depths around the outer steel pipe 1. The length of the inner steel pipe 2 is longer than the length of the outer steel pipe 1, and the outer diameter is smaller than the inner diameter of the outer steel pipe 1. The bottom end is processed into a wedge-shaped end 4. The wedge-shaped end and The transition zone of the straight part is processed as an arc surface.

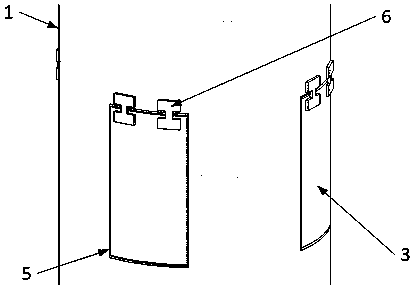

[0032] The installation method of expansion anchor fluke is as follows: image 3 As shown, the expansion anchor fluke 3 is in the shape of a flat triangular prism as a whole, and the bottom is processed as an arc surface; the outer steel pipe wall is processed with a square opening 5; the expansion anchor fluke 3 is placed in the opening 5, and its side is flush with the outer wall of the outer steel pipe...

Embodiment 2

[0036] A construction method for rapid expansion of steel pipe piles, including the following steps:

[0037] S1, level the site, set out the line to determine the pile position, excavate the hole 7, the depth of the hole 7 is less than the length of the outer steel pipe 1, and the diameter of the hole is larger than the diameter of the outer steel pipe 1;

[0038] S2, such as Figure 5 As shown, lower the outer steel pipe 1 to the hole 7;

[0039] S3, lift the inner steel pipe 2 to the top of the outer steel pipe 1, first insert the bottom end of the inner steel pipe 2 into the outer steel pipe 1, then Figure 5 detailed figure 1 As shown, steel rope 8 is used around the pile body to connect the inner steel pipe wall with the top of the outer steel pipe, and the winch 9 is used to wind the steel rope 8, thereby pulling the inner steel pipe 2 into the outer steel pipe 1; For the self-balancing of the inner steel pipe, use the winch 9 to insert the inner steel pipe 2 into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com