Joint of steel pipe concrete column and cast-in-place reinforced concrete beam and construction method of joint

A technology for reinforced concrete beams and CFST columns, which is applied to the joints of CFST columns and cast-in-place reinforced concrete beams and their construction fields, can solve the problems of low connection reliability, stress deformation at the welded part of the steel pipe columns, and low bearing capacity of nodes. , to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

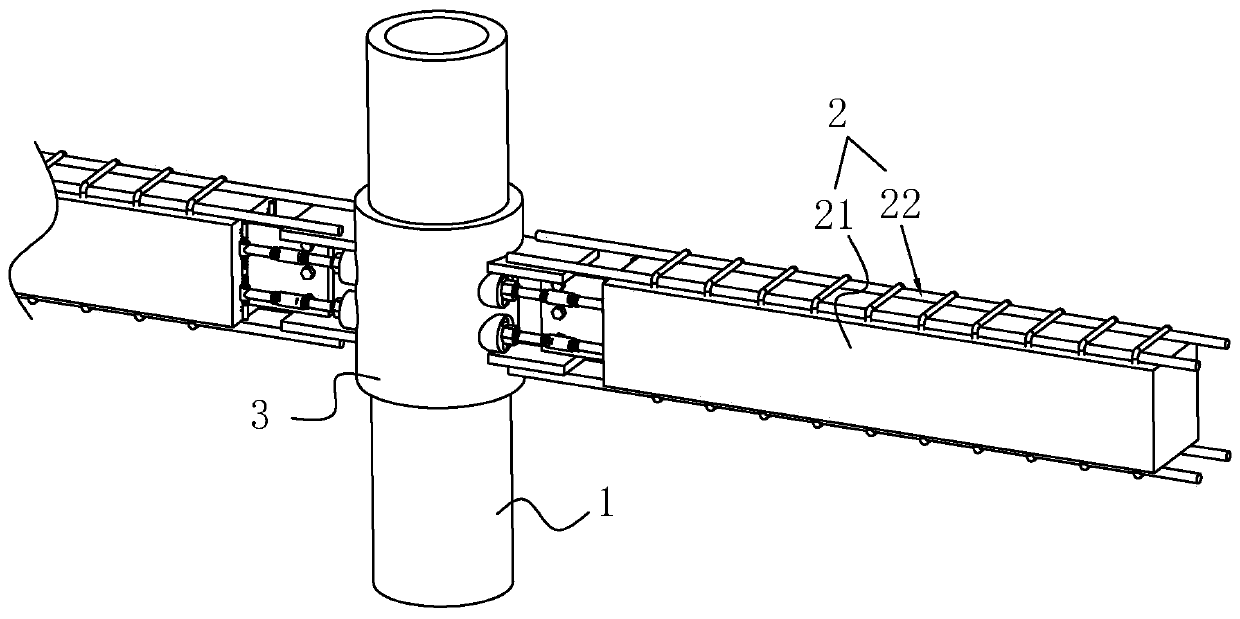

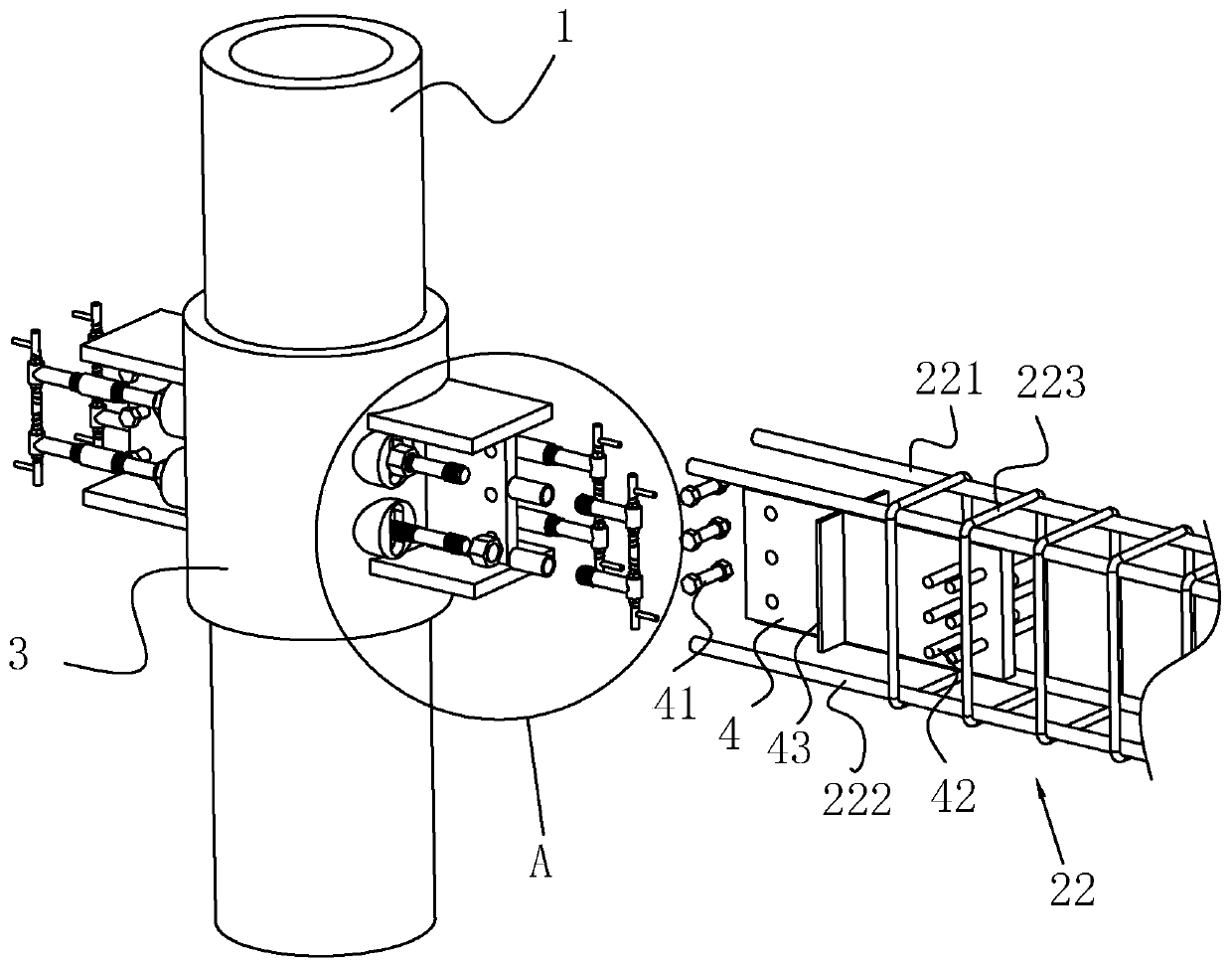

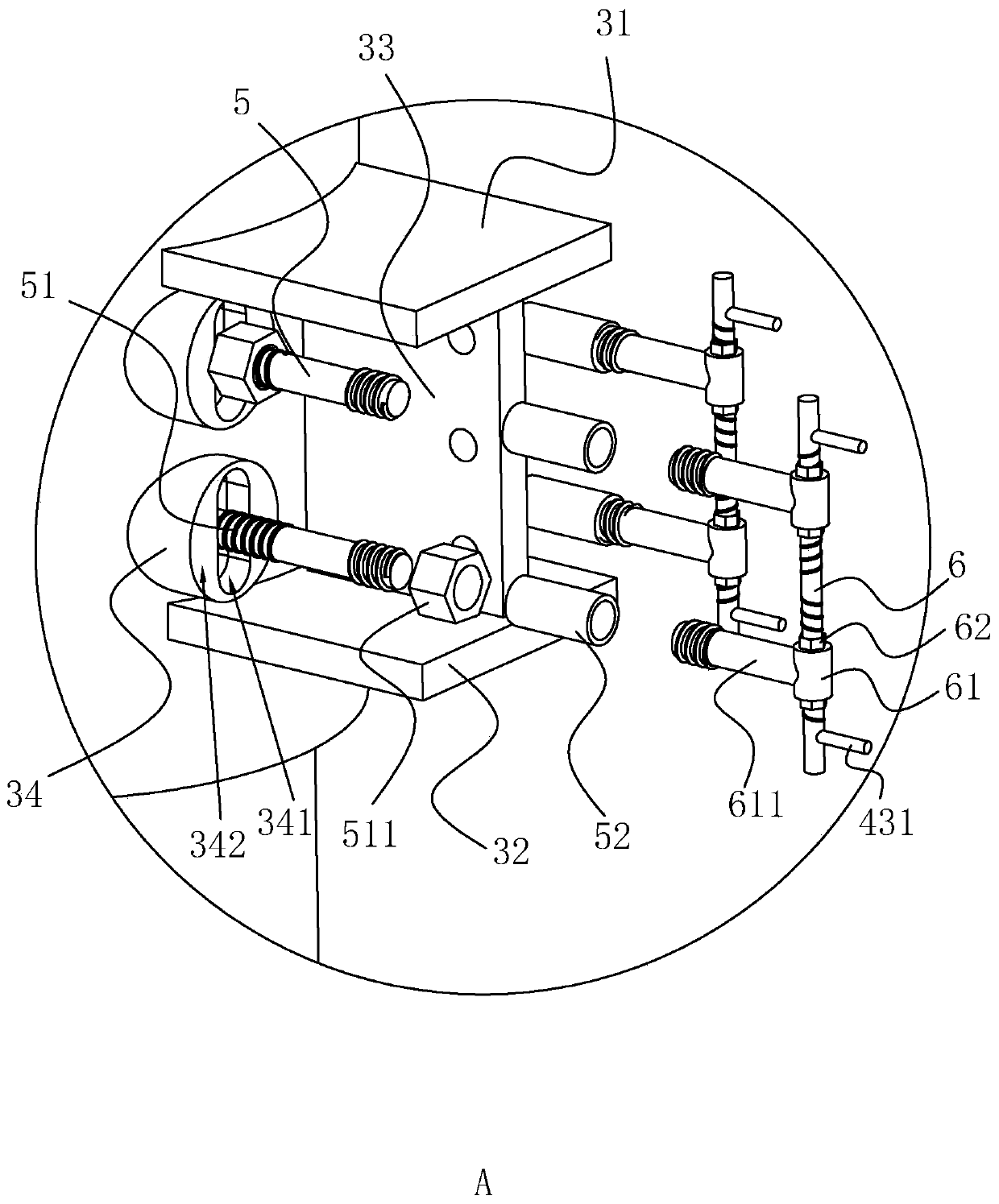

[0041] like figure 1 , 2 As shown, a joint between a steel pipe concrete column and a cast-in-place reinforced concrete beam includes a steel pipe column 1 and a concrete beam 2, and also includes a casing 3 fixedly sleeved on the steel pipe column 1, and the casing 3 is made of steel. The steel pipe column 1 is provided with steel bars and poured with concrete. An upper cover plate 31 and a lower cover plate 32 are fixedly arranged on the sleeve pipe 3, and a connection plate 33 is fixedly arranged on the sleeve pipe 3. The connection plate 33 is located between the upper cover plate 31 and the lower cover plate 32, and the two ends of the connection plate 33 Welded with the upper cover plate 31 and the lower cover plate 32 respectively;

[0042] like figure 2 , 3 As shown, the concrete beam 2 includes a concrete structure 21 and a reinforcement cage 22. The reinforcement cage 22 includes an upper main reinforcement 221, a lower main reinforcement 222 and a stirrup 223. ...

Embodiment 2

[0055] S1, mark the installation position of the casing 3 on the reinforcement column;

[0056] S2. Set the casing 3 at the position marked on the reinforcement column, and fix the location of the casing 3;

[0057] S3. Install the connecting rod 5, insert the connecting rod 5 into the casing 3 and the steel pipe column 1, and adjust the position of the connecting rod 5 so that the lengths of the two ends of the connecting rod 5 protruding from the casing 3 are equal, and tighten the limit nut 511 ;

[0058] S4, install the reinforcement cage 22, connect the connecting plate 33 with the embedded plate 4 through the connecting bolt 41, weld the upper main rib 221 on the upper cover plate 31, and weld the lower main rib 222 on the lower cover plate 32;

[0059] S5. Pour concrete into the reinforcement cage 22 to form the concrete beam 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com