Hard rock cutterhead of multi-angle rock breaking cantilever heading machine

A cantilever roadheader and multi-angle technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as abnormal wear and chipping of hobs, and achieve the goal of ensuring construction progress, service life, and design rationality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

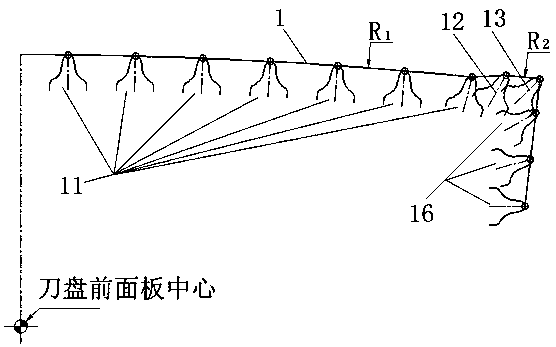

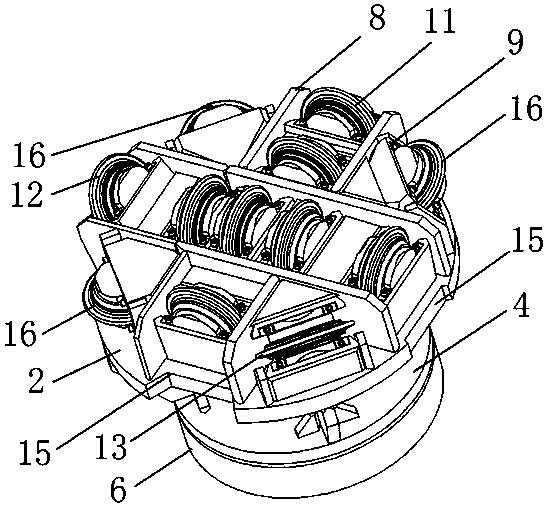

[0039] Embodiment 1, a kind of hard rock cutterhead of multi-angle rock-breaking cantilever roadheader, such as Image 6As shown, it includes a cutting arm 14 and a cutterhead front panel 2 connected to the cutting arm 14. The front end of the cutterhead front panel 2 is provided with a front hob 11 and a side hob 16, and the cutting arm 14 can drive the cutterhead. Front panel 2 follows. As the cutting arm 14 moves forward, the front hob 11 on the front panel 2 of the cutter head cuts into the hard rock in a forward direction; The side hob 16 performs lateral cutting on hard rock.

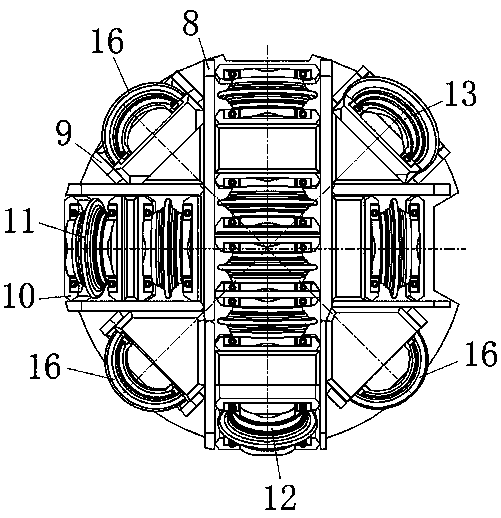

[0040] Such as figure 2 with image 3 As shown, a main beam 8 and a sub-beam 9 are arranged on the front panel 1 of the cutter head, hob welding seats 10 are arranged inside the main beam 8 and the sub-beam 9, and the front hob 11 is arranged in the main beam 8 The hob welding seat 10 of the side beam 16 and the inflection point hob 13 are arranged in the hob welding seat 10 of the sub-beam 9...

Embodiment 2

[0046] Embodiment 2, a hard rock cutterhead of a multi-angle rock-breaking cantilever roadheader, such as Figure 5 As shown, the cutter ring of the inflection point hob 13 is the first eccentric cutter ring 131, and the outermost blade of the first eccentric cutter ring 131 exceeds the outer edge of the outer end cover of the inflection point hob 13, which can effectively prevent the cutter head from cutting forward During the rock mass or when the cutterhead cuts the rock mass laterally, the rock mass wears the outer end cover of the inflection point hob 13 .

[0047] Further, the cutter ring of the inflection point hob 13 is a large-diameter cutter ring, and the height of the leading edge of the large-diameter cutter ring exceeds the highest point of the inner end cover of the inflection point hob 13, which can effectively prevent the cutter head from cutting into the rock mass in a forward direction. When or when the cutter head cuts the rock mass laterally, the rock mass ...

Embodiment 3

[0050] Embodiment 3, a hard rock cutter head of a multi-angle rock-breaking cantilever roadheader, a lateral transition hob 12 is arranged between the inflection point hob 13 and the front hob 11, and the front end of the lateral transition hob 12 is The distance between the blade and the hinge point of the cutting arm 14 is greater than R 1 , to further ensure that when the cutter head cuts the rock mass laterally, the lateral transition hob 12 and the inflection point hob work together to protect the front hob 11 from lateral force when cutting the lateral rock mass, preventing During cutting, the front hob 11 is abnormally worn and broken.

[0051] Further, the cutter ring of the lateral transition hob 12 is a second eccentric cutter ring, and the outermost edge of the second eccentric cutter ring exceeds the outer edge of the outer end cover of the lateral transition hob 12, which can effectively prevent the cutter head from When cutting into the rock mass or when the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com