Welding inspection ruler inspection device

A technology of inspection devices and detection devices, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of waste of verification resources, large measurement errors, and inability to carry, so as to achieve easy pick-and-place and carry, reduce errors, The effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

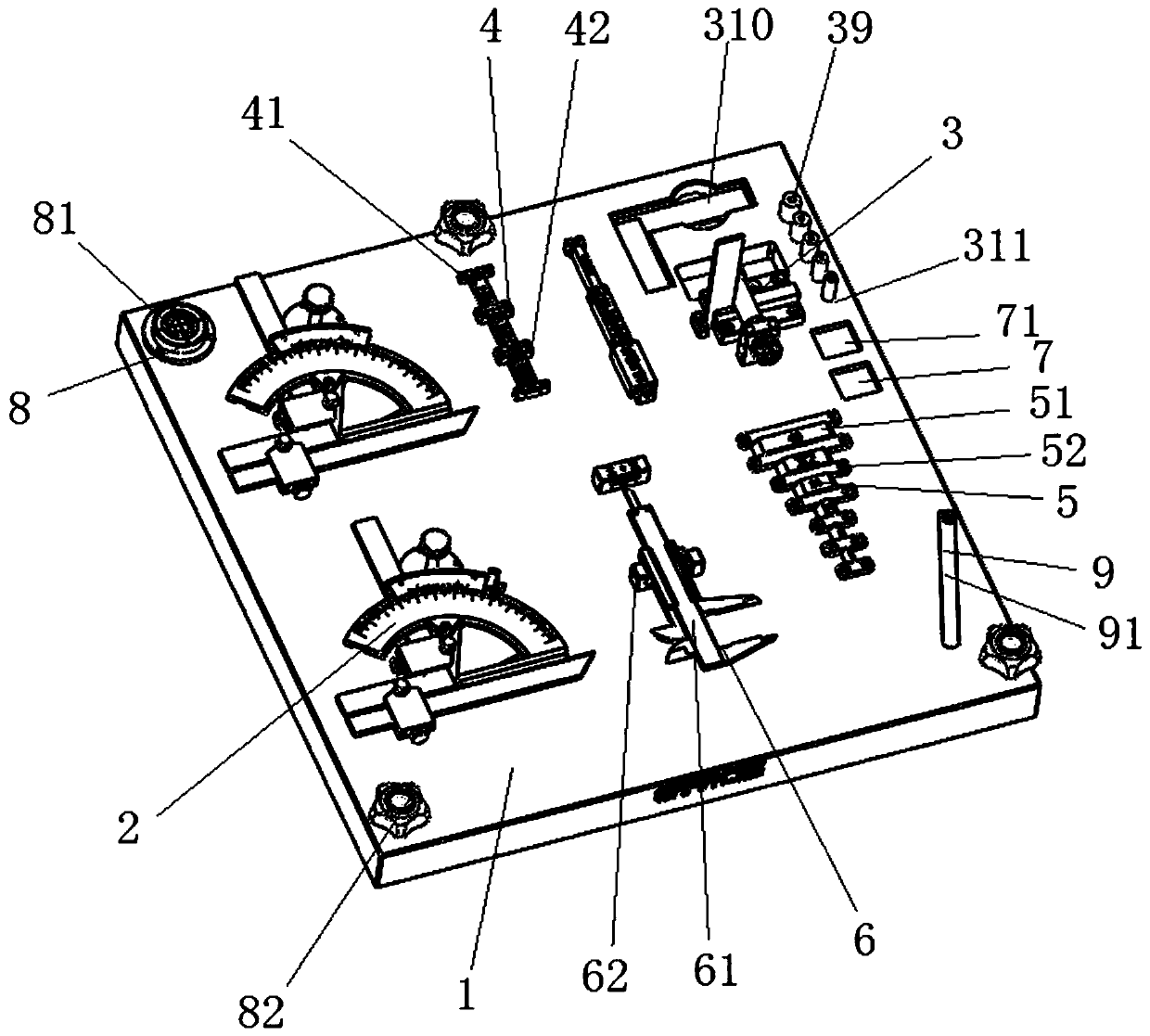

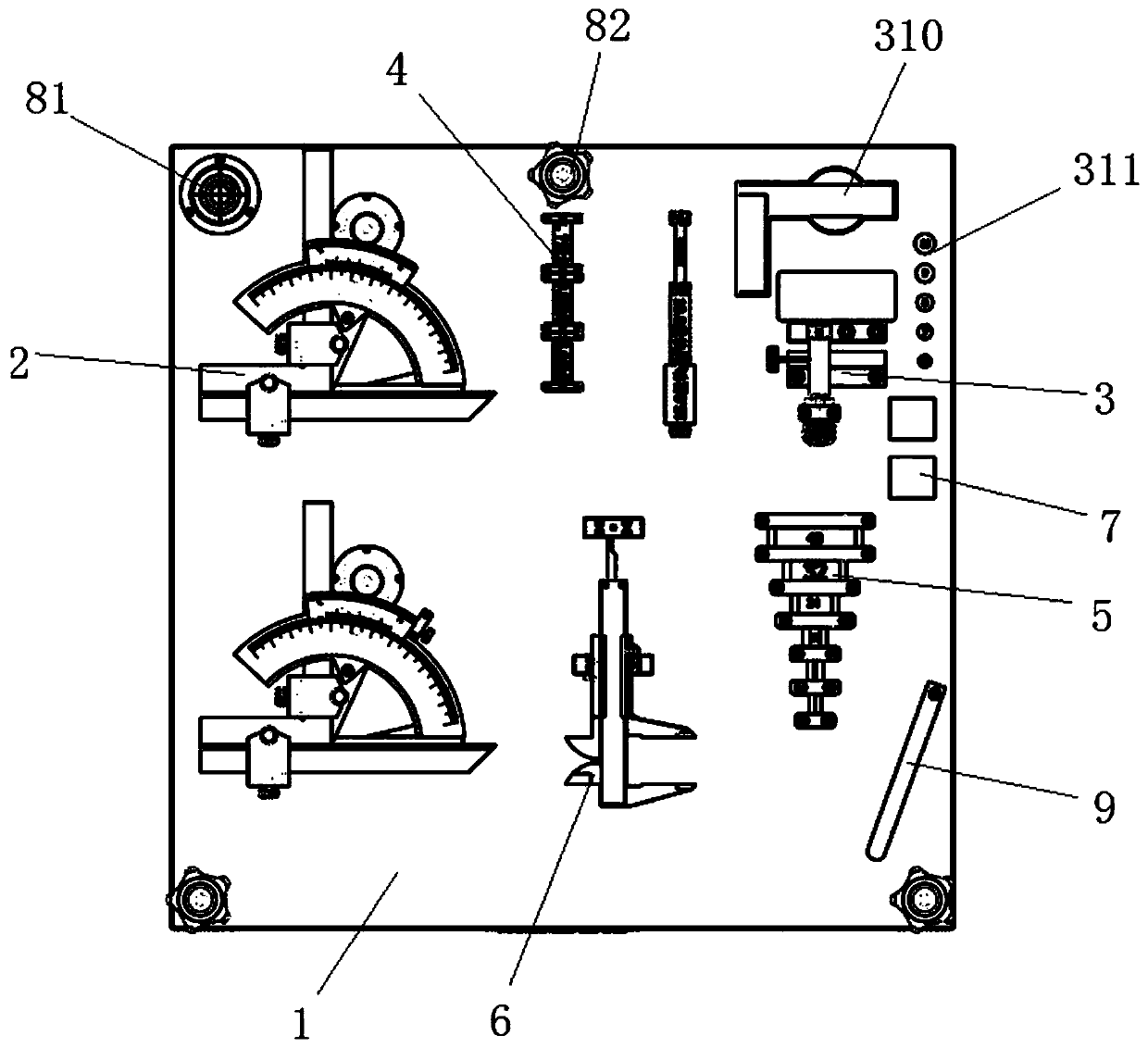

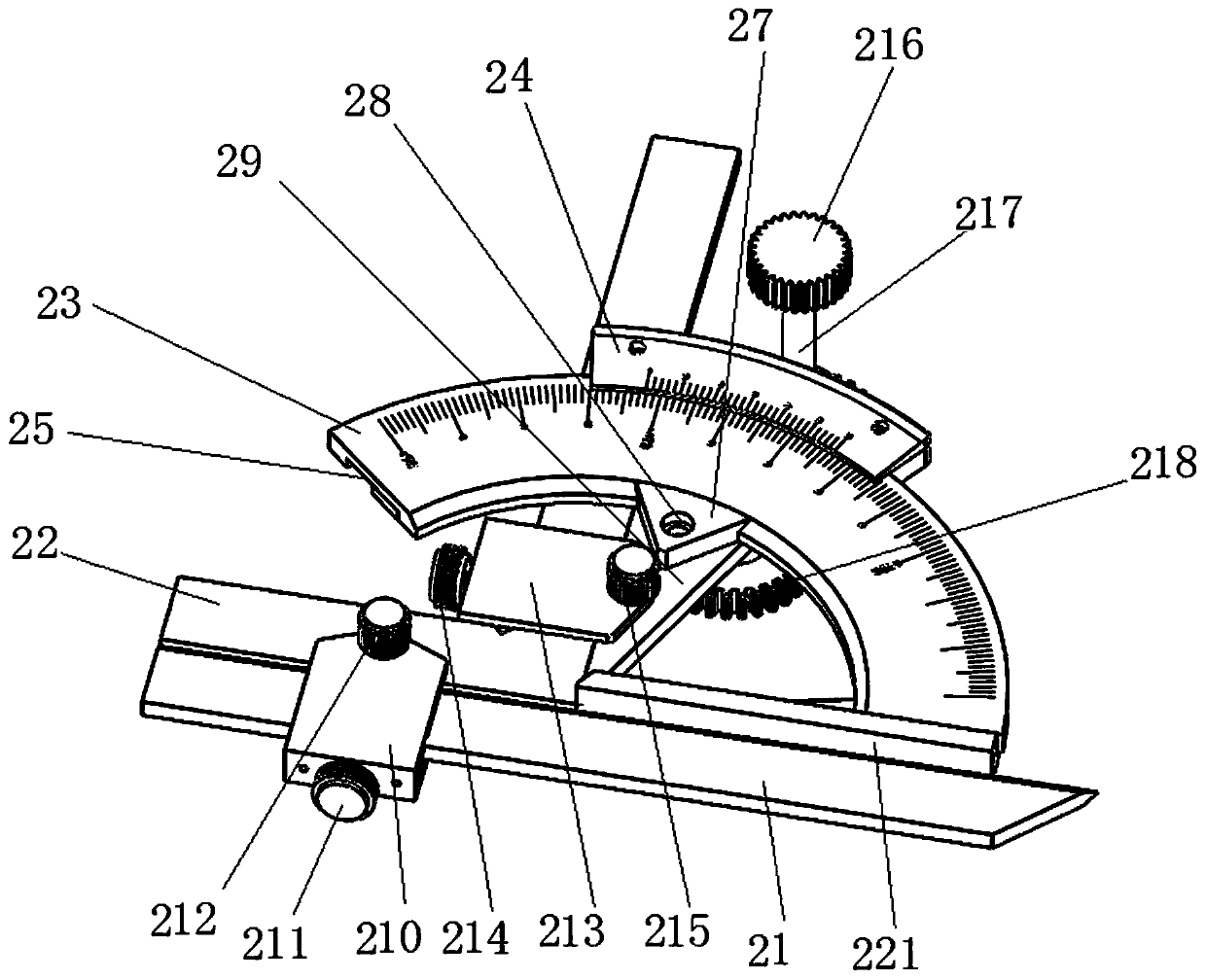

[0045] A welding inspection ruler inspection device, combined with Figure 1 to Figure 16 As shown, it includes a box body and a detection platform 1 arranged in the box body. The detection platform 1 is detachably provided with an angle parameter detection device 2, a height gauge indication error measurement device 3, a depth parameter detection device 4, and a width scale indication value. Error measuring device 5, gap gauge indication error measuring device 6, surface roughness difference measuring device 7, and up-and-down distance measuring device 9, all the above-mentioned standard instruments can be fixed, avoid hand-holding as much as possible, and at the same time facilitate disassembly and traceability, and verify stability Significantly increased.

[0046] The selection of testing platform 1: including the specifications,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com