A miniaturized, high-density optical fiber connector and its production equipment

A technology for fiber optic connectors and production equipment, applied in the directions of instruments, optics, light guides, etc., can solve the problems of no auxiliary connecting mechanism, manual docking, affecting the optical path, etc., to ensure the waterproof effect, ensure the connection, and ensure the tight effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

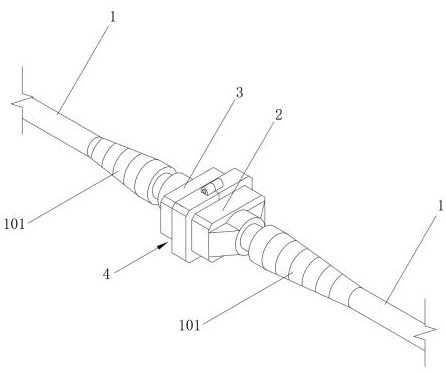

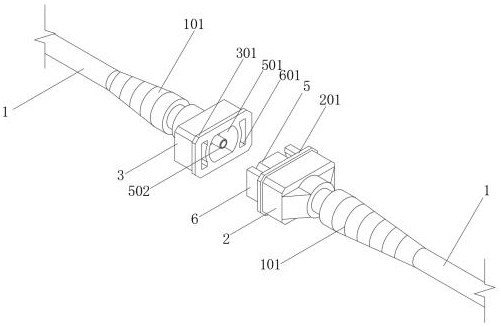

[0024] The present invention provides such Figure 1-3 A miniaturized, high-density optical fiber connector shown includes two groups of optical fiber main bodies 1 with flexible parts 101, and the flexible parts 101 of the two groups of optical fiber main bodies 1 are respectively connected to the first connector 2 and the second connector 3 connection, the first connector 2 and the second connector 3 are plug-fitted, and the first connector 2 is configured with a first extending rib 201 on the periphery of one side facing the second connector 3, and the second connector The periphery of the head 3 facing the first connecting head 2 is configured with a second extending rib 301, the first extending rib 201 and the second extending rib 301 abut against each other, and the first extending rib 201 and the second extending rib 201 abut against each other. A waterproof sealing member 4 for limiting the first connecting head 2 and the second connecting head 3 is arranged outside th...

Embodiment 2

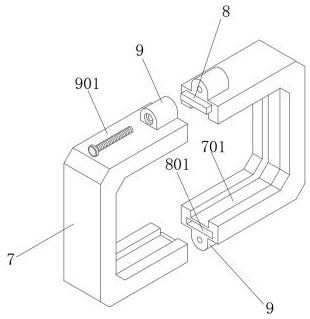

[0031] The present invention provides such Figure 4-5 The production equipment for a miniaturized, high-density optical fiber connector shown includes a set of mounting substrates 10 in a rectangular plate-like structure and a positioning base 13 and a movable base 14 arranged above the mounting substrate 10. The mounting substrates The two ends of 10 are equipped with side limit vertical plates 11, and a set of matching slide rails 12 is arranged between the two groups of side limit vertical plates 11, and the positioning base 13 is fixedly installed on the side limit vertical plates. One side of the board 11 , the movable base 14 is movably installed on the side of the matching slide rail 12 away from the positioning base 13 .

[0032] Specifically, above the positioning base 13 and the movable base 14, a limit clip 18 and an alignment rubber clip 19 are arranged, and the limit clip 18 is arranged on the upper end faces of the positioning base 13 and the movable base 14. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com