Fiber optic connectors and their tail wiring assemblies

A technology for optical fiber connectors and wiring components, applied in optical components, instruments, optics, etc., can solve the problems of low reliability and pass rate, scratches and damage, avoid low reliability and pass rate, ensure safety, The effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

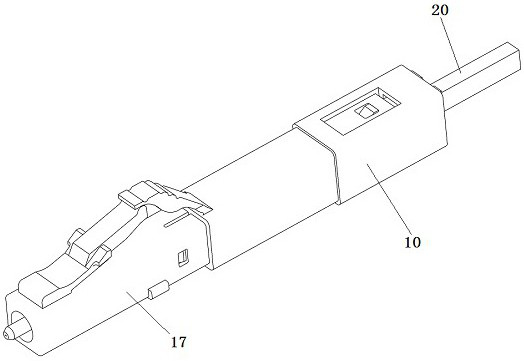

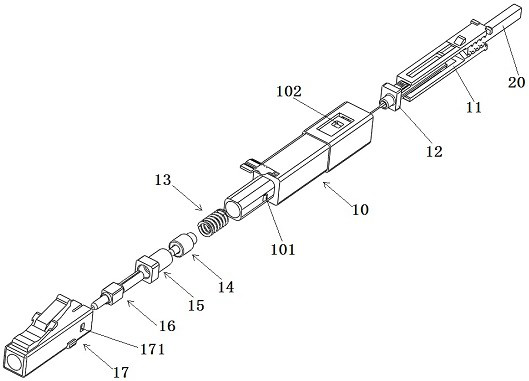

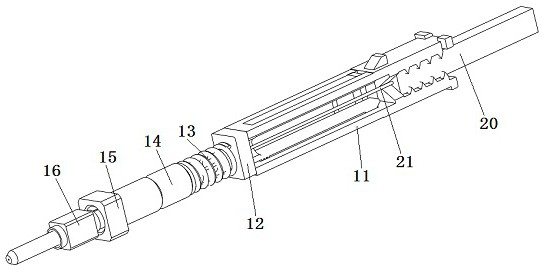

[0092] Embodiment 1 of the optical fiber connector in the present invention: the optical fiber connector in this embodiment is used to connect LC-type optical fibers, and can meet the requirement of fast on-site wiring of LC-type optical fibers. like figure 1 and figure 2 As shown, the optical fiber connector mainly includes a front housing 17, a ferrule assembly and a tail wiring assembly, and the tail wiring assembly includes a main housing 10, a fiber protection sliding sleeve 12 and an optical cable fixing member 11, which constitute the components of the optical fiber connector. There are many, so the structure of each part of the fiber optic connector is now explained.

[0093] The main housing 10 in the tail wiring assembly is installed on the rear end of the front housing 17 when assembling the optical fiber connector, and is assembled with the front housing 17 to form a shell, and the two sides of the main housing 10 are provided with triangular main housings buckl...

Embodiment 2

[0112]Embodiment 2 of the optical fiber connector in the present invention: the difference from the above-mentioned embodiments is that in this embodiment, the fiber protection sliding sleeve is inserted into the optical cable fixing member, and the wall surface in the optical cable fixing member that cooperates with the fiber protection sliding sleeve A rubber strip or a frosted surface is arranged on the upper part, and the friction force between the fiber protection sliding sleeve and the rubber strip or the frosted surface is large, which can realize the sliding resistance cooperation between the fiber protection sliding sleeve and the optical cable fixing member in the direction of the insertion sleeve. When the fiber protection sliding sleeve is extended, the operator needs to exert force to overcome the friction between the fiber protection sliding sleeve and the optical cable fixing member, so that the fiber protection sliding sleeve can be extended or retracted into the...

Embodiment 3

[0113] Embodiment 3 of the optical fiber connector in the present invention: The difference from the above-mentioned embodiments is that the size of the largest outline of the fiber protective sliding sleeve in this embodiment is larger than that of the optical cable fixing member, and the optical cable fixing member is inserted and sleeved on the fiber protection. in sliding sleeve. A slider is arranged on the outer surface of the optical cable fixing piece, and a guide groove is arranged on the inner wall surface of the fiber protection sliding sleeve. In other embodiments, the cross sections of the fiber protection sliding sleeve and the optical cable fixing member are both rectangular or circular, and the fiber protection sliding sleeve and the optical cable fixing member are guided and matched by the inner and outer surfaces of the fiber protection sliding sleeve and the optical cable fixing member.

[0114] Embodiment 4 of the optical fiber connector in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com