Diagnosis Method of Mold State for Fastener Forming Machine

A state diagnosis, molding machine technology, applied in the direction of nuclear method, neural learning method, registering/instructing the work of the machine, etc., can solve the problem that the processing machine cannot immediately detect the processing quality, save data processing time, and detect early. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

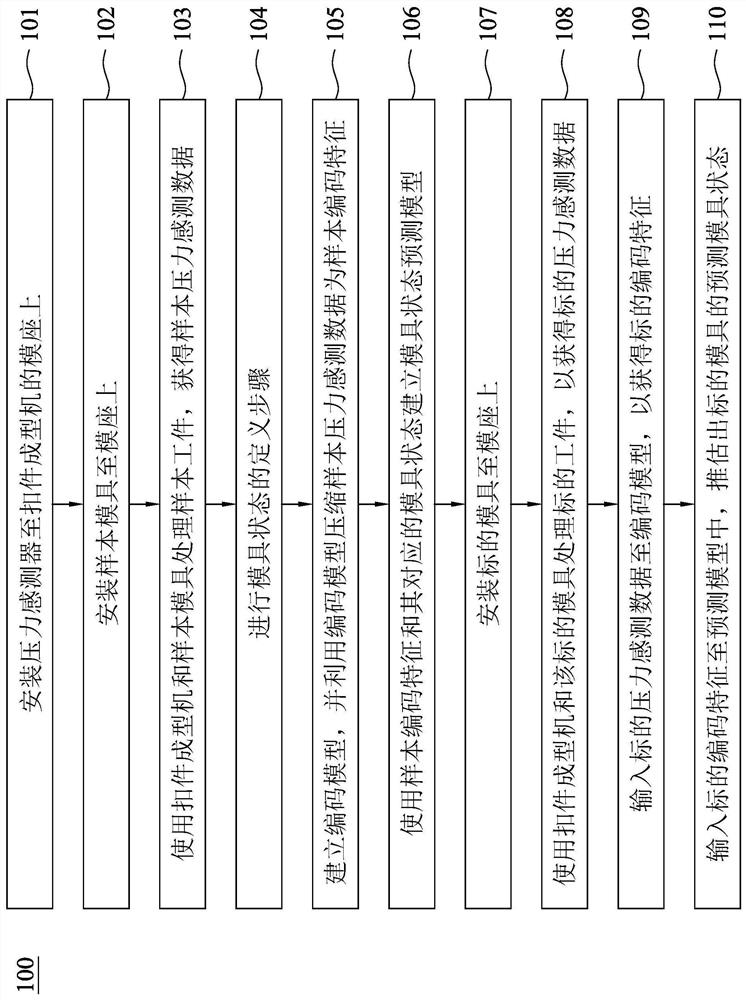

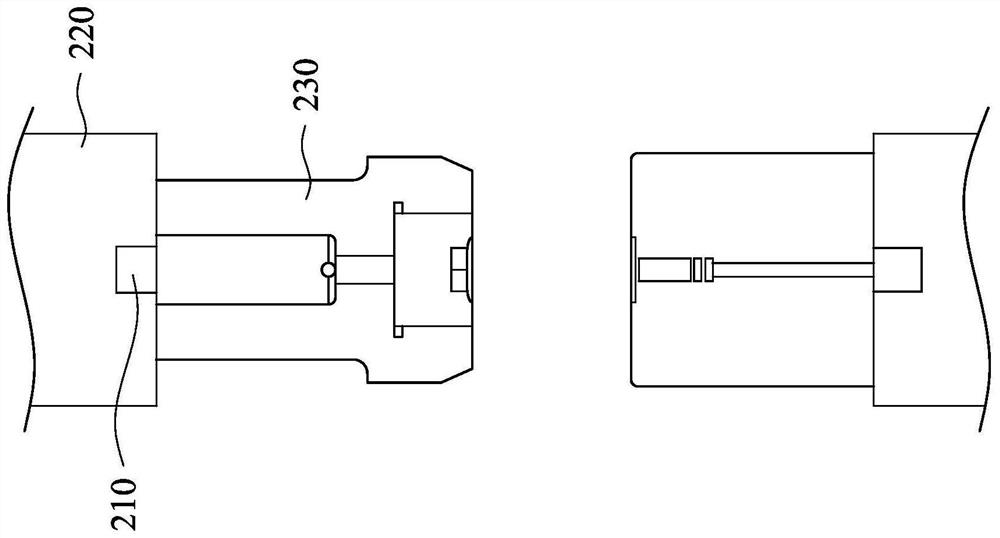

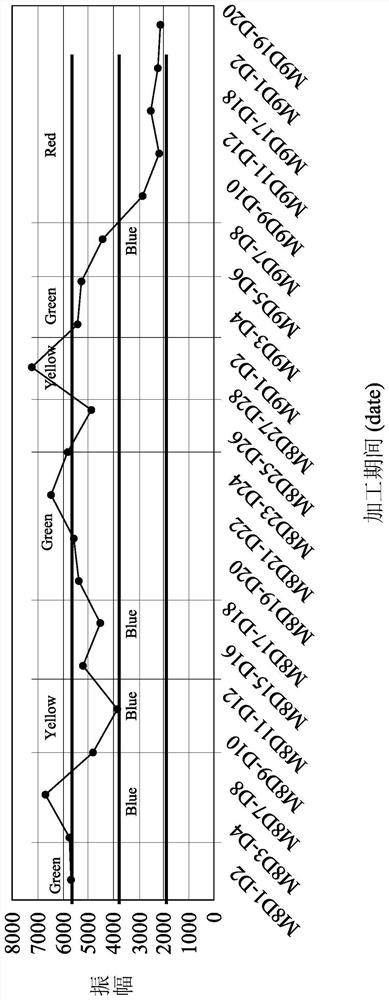

[0022] Please also refer to figure 1 and figure 2 , figure 1 It is a schematic flowchart illustrating a method for diagnosing the mold state of a fastener forming machine according to an embodiment of the present invention, figure 2 It is a partial device schematic diagram illustrating a fastener forming machine according to an embodiment of the present invention. The mold state diagnosis method 100 of this embodiment mainly includes the following steps. Firstly, step 101 is performed to install at least one pressure sensor 210 on the mold base 220 of the fastener forming machine. Next, step 102 is performed to install the sample mold 230 on the mold base 220 of the fastener forming machine. Then, step 103 is performed to process a plurality of sample workpieces by using the fastener forming machine and the sample mold 230 to obtain multiple sets of sample pressure sensing data. In some embodiments, the sample pressure sensing data is a forging force waveform change gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com