Surface rust-proof treatment device for motor casing machining

A technology of anti-rust treatment and electric motors, which is applied in the direction of electromechanical devices, manufacturing motor generators, injection devices, etc., can solve the problems of poor rotation adjustment effect of the motor casing, long delay, and insufficient flexibility, etc., to ensure fixed connection Effect, guaranteed spraying effect, effect of shortening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

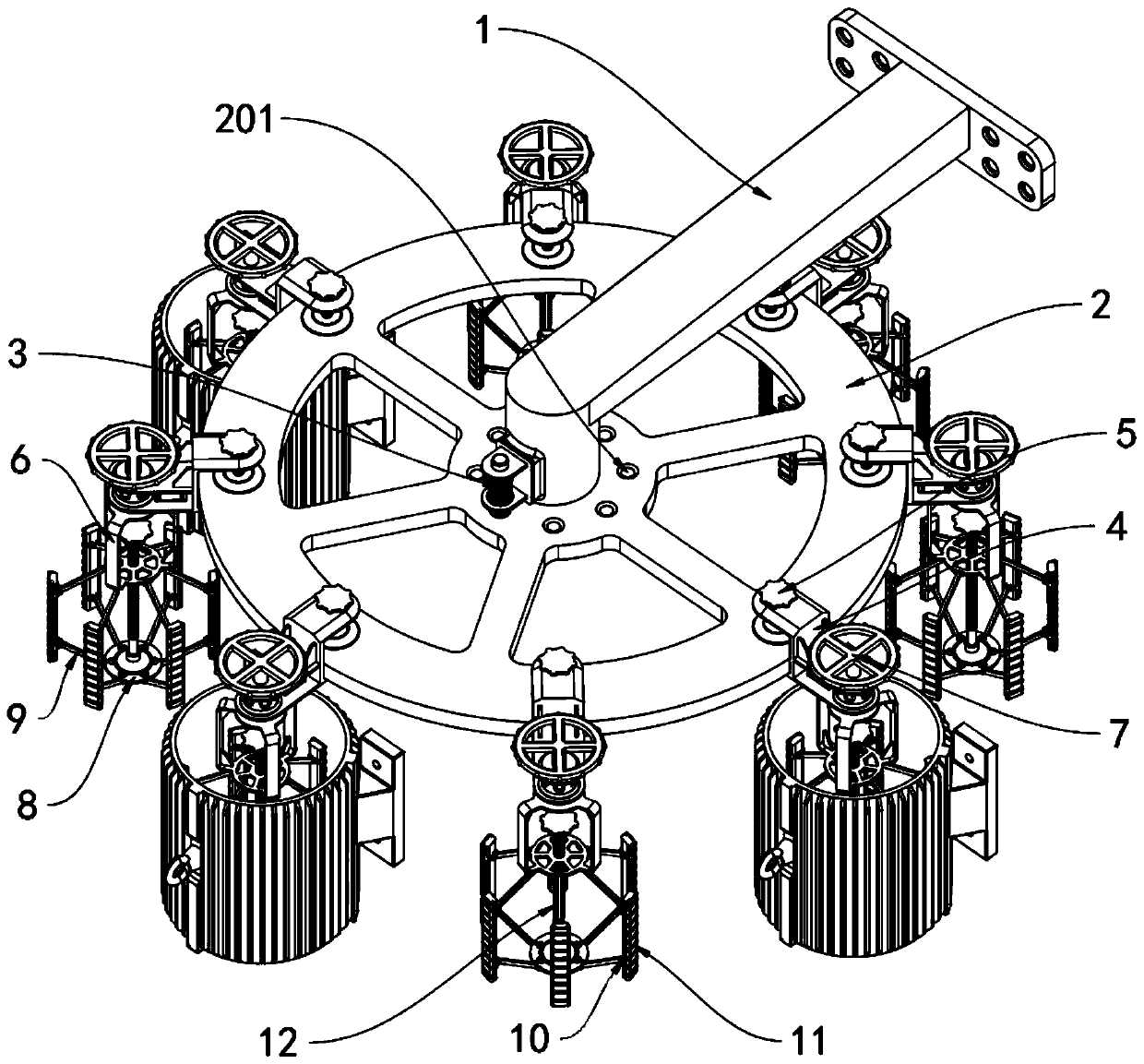

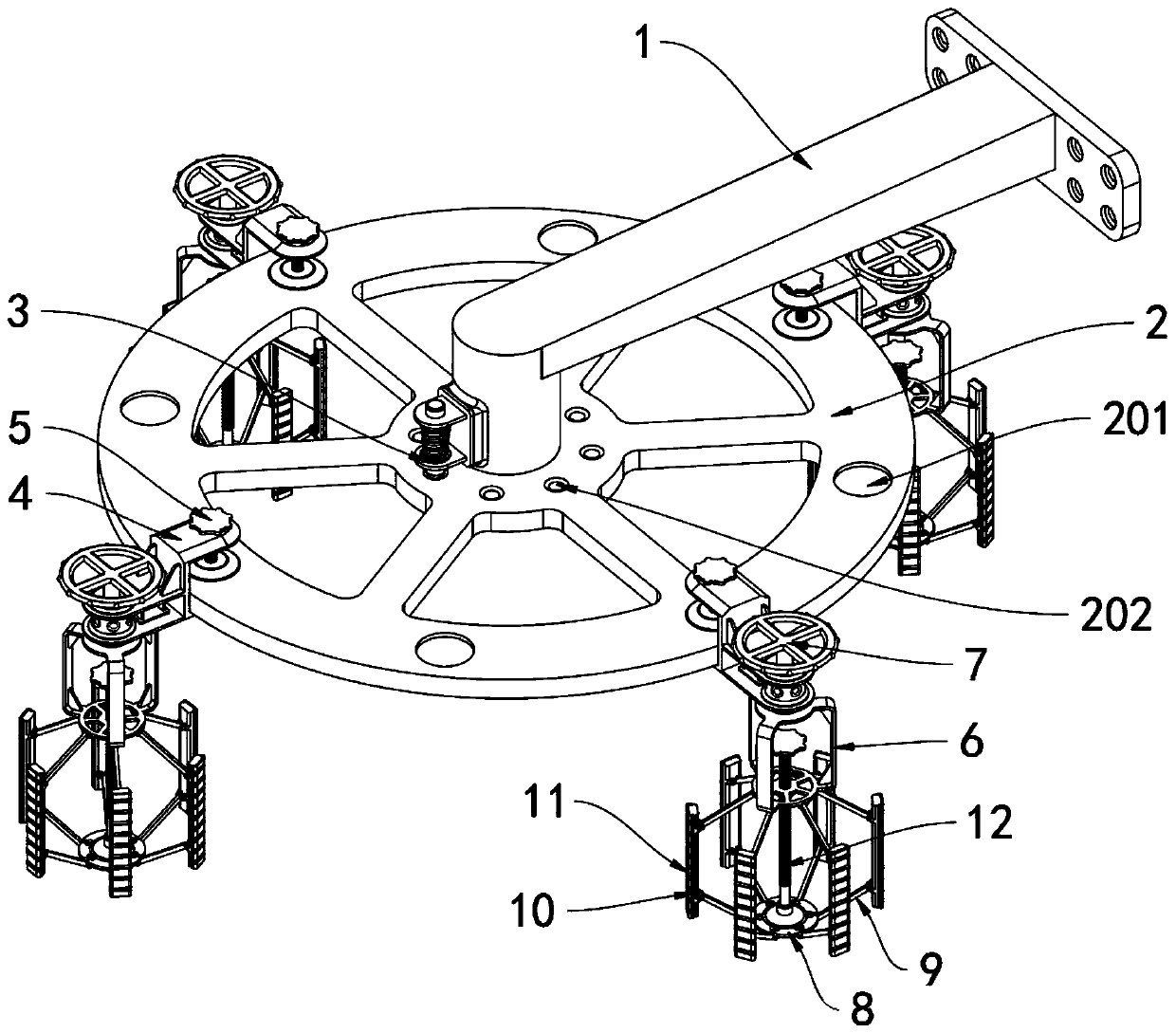

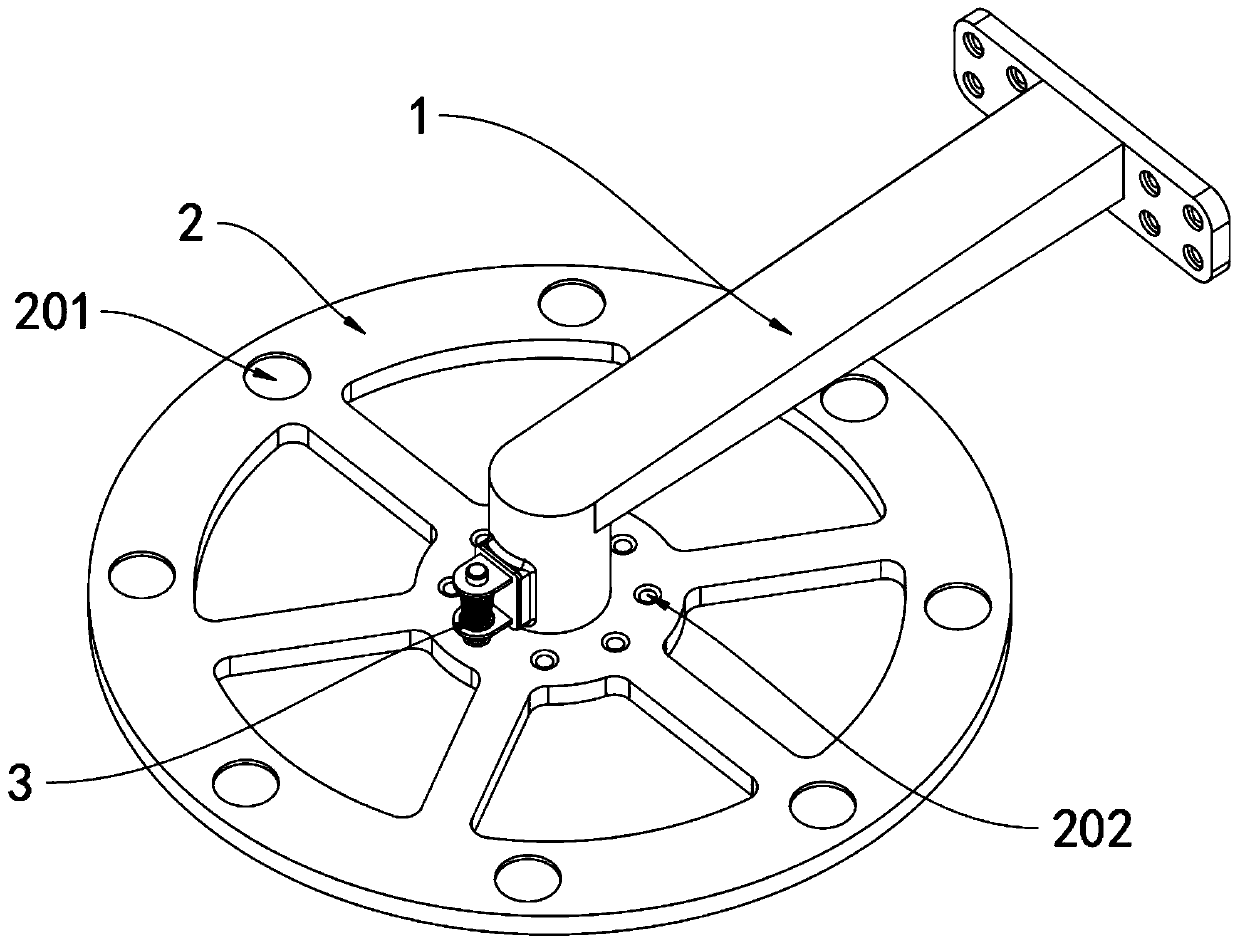

[0032] as attached figure 1 To attach Figure 10 Shown:

[0033]The invention provides a surface anti-rust treatment device for motor casing processing, which includes a receiving runner 2, a limit mechanism 3, a connecting piece 4, a receiving frame 6, a chassis 8, a rubber anti-skid pad 11 and an adjusting screw 12; the receiving runner 2 is connected to the bottom of the front end of the support frame 1, and the receiving runner 2 is a circular hollow structure; there are two limit mechanisms 3, and the limit mechanisms 3 are respectively located inside the connector 4 and on the outer wall of the support frame 1; the connector 4 There are many places, and the rear end of the connecting piece 4 is connected to the periphery of the receiving runner 2 in a circular shape through the clamping bolt 5; the receiving frame 6 is a hollow structure, and the top of the receiving frame 6 is connected to the front end of the connecting piece 4, and the receiving frame 6 passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com