Camera module and terminal equipment

A technology of camera module and terminal equipment, which is applied in the field of cameras, can solve problems such as camera running out of focus, unclear pictures taken by customers, UV glue penetration, etc., to reduce the defective rate of production and assembly, reduce the processing process, and reduce production costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing this is further described.

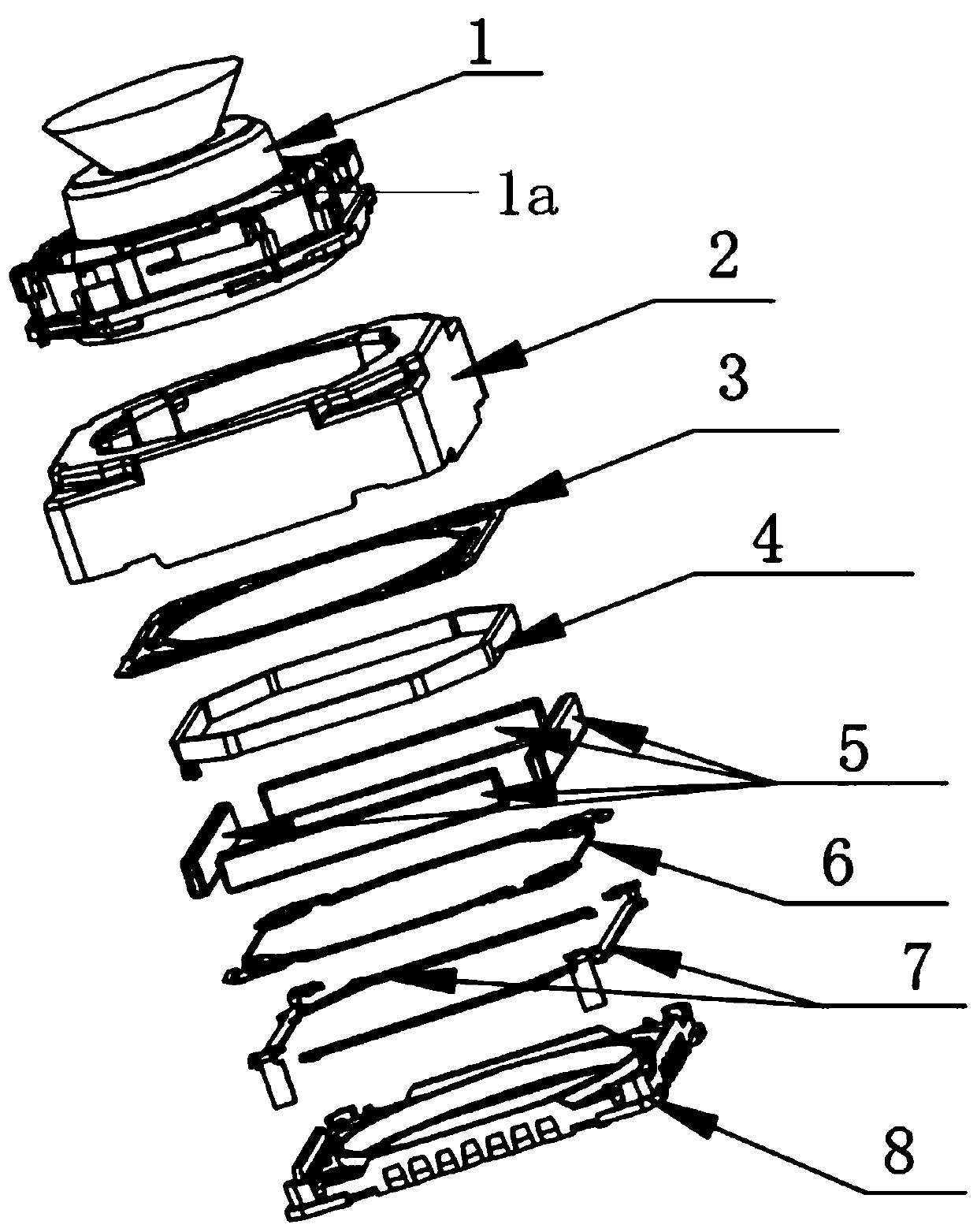

[0024] Such as figure 1 As shown, in this embodiment, a camera module includes a lens 1, a motor housing 2, a motor upper shrapnel 3, a drive coil 4, a drive magnet group 5, a motor lower shrapnel 6, a motor PIN terminal 7 and a motor base 8 , the connection relationship of the above components is as follows:

[0025] The lens 1 is fitted in the motor housing 2 so that it can move up and down. The elastic piece 3 on the motor is arranged between the stepped surface 1 a in the middle of the lens 1 and the inner top wall of the motor housing 2 , and the elastic piece 3 on the motor is connected to the lens 1 and the motor housing 2 respectively. The driving coil 4 is wound on the lens 1, and the driving coil 4 is used for electrical connection with the control circuit board; the control circuit board controls the driving current input to the driving coil 4 to control the driving magnet group 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com