A kind of 3D electrospinning method and its equipment

A kind of electrostatic spinning and 3D technology, which is applied in the direction of processing and manufacturing, additive processing, liquid material additive processing, etc., can solve the problems of uneven thickness and aperture, slow molding, long time required, etc., achieve strength and toughness, and speed up production rate , Increase the effect of foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A 3D electrostatic spinning method, comprising the following steps:

[0039] S1, making the polymer spinning liquid foam through a bubble generating device, and adding an ionic compound to the polymer spinning liquid;

[0040] S2, applying an electrostatic field to the foam, the electrostatic field is provided by a constant voltage source, and the electrostatic field is used to provide an electric field force to guide the foam to flow into the operating cabin;

[0041] S3, store the foam in the operating cabin, and operate the operating cabin under negative pressure to burst the foam;

[0042] S4, obtaining a 3D electrospun fabric.

[0043] Further, in step S2, the magnitude of the electrostatic field is controlled to control the thickness of the foam layer.

Embodiment 2

[0045] A 3D electrospinning method,

[0046] The difference between this embodiment and embodiment one is:

[0047] The electrostatic field is provided by an AC source, and the magnitude of the electrostatic field is controlled to control the shape of the foam layer.

Embodiment 3

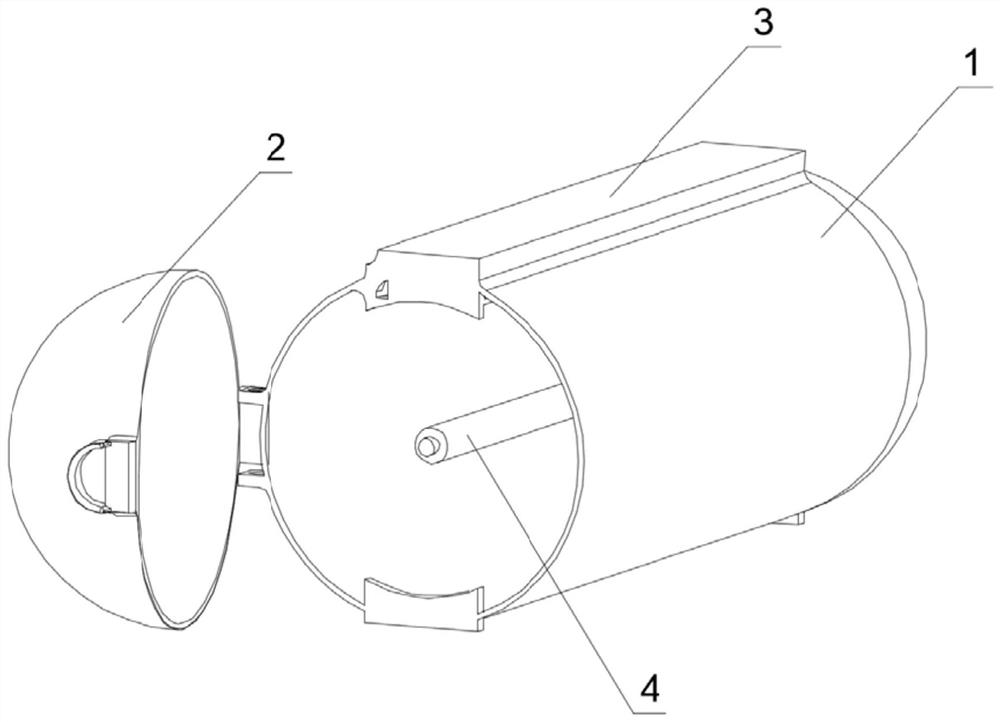

[0049] Provide a kind of 3D electrospinning equipment of described method, described equipment comprises:

[0050] A cylinder 1, the cylinder 1 is provided with an openable and closable sealing cover 2, and the cylinder 1 is connected to a corresponding negative pressure generating device (not shown);

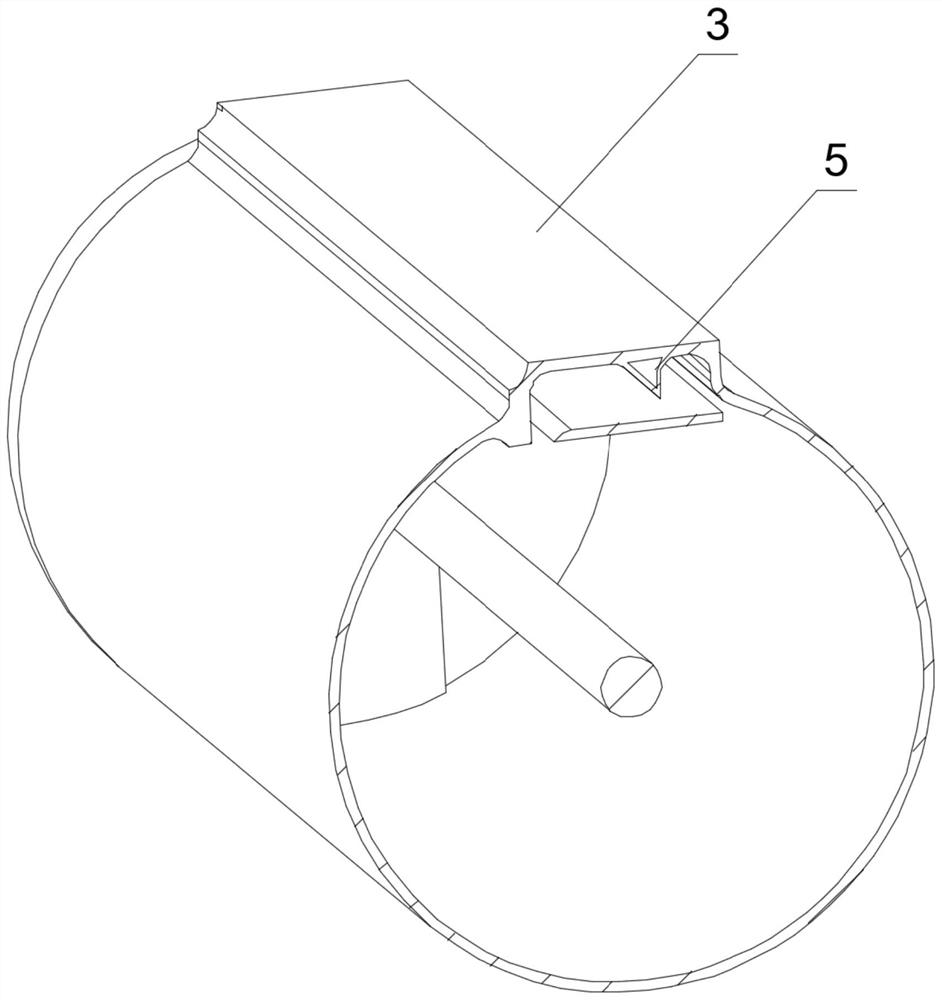

[0051] The functional cavity 3 is arranged on the side wall of the cylinder body 1, and communicates with the cylinder body 1 through a corresponding communication groove, wherein the functional cavity is provided with:

[0052] The bubble generator 5 is connected to the corresponding gas source and the polymer textile liquid source, the bubble end of the bubble generator 5 faces the inside of the cylinder 1, and the angle of the bubble end of the bubble generator is adjustable;

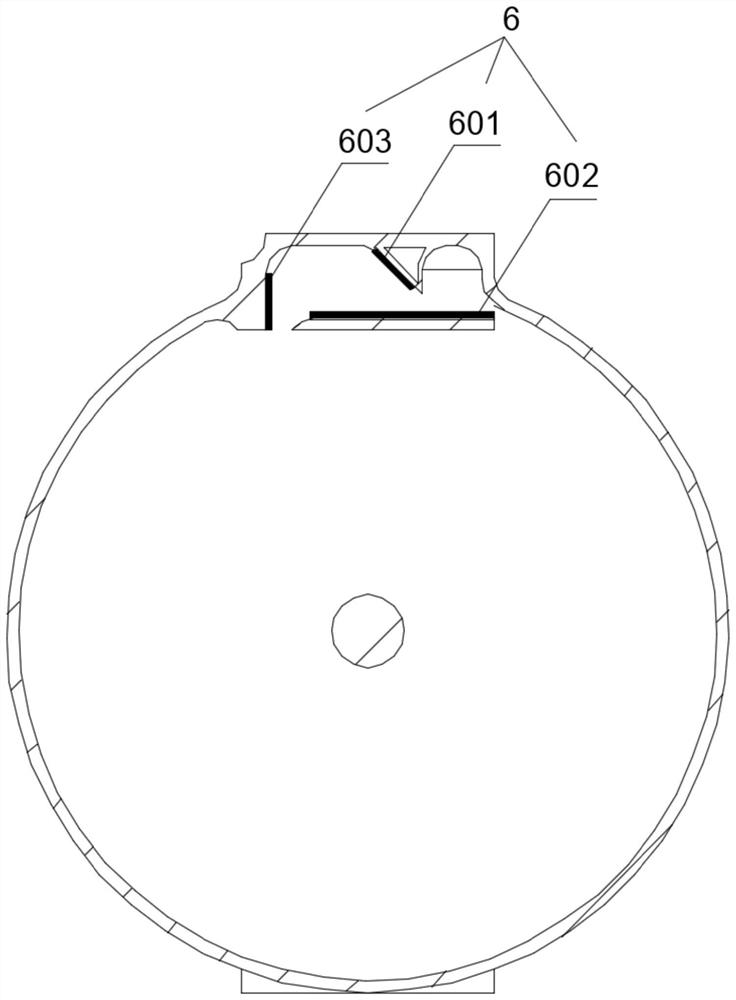

[0053] A plurality of electrode plates 6 are connected to the power supply, wherein at least one electrode plate 6 is arranged adjacent to the communicating groove.

[0054] Further, the cylinder bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com