Ceramic photocuring slurry and preparation method thereof

A light-curing, ceramic technology, applied in the field of materials, can solve problems such as affecting the stability of the paste and printing stability, and achieve the effects of avoiding uneven printing performance, good storage stability, and high anti-settling properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

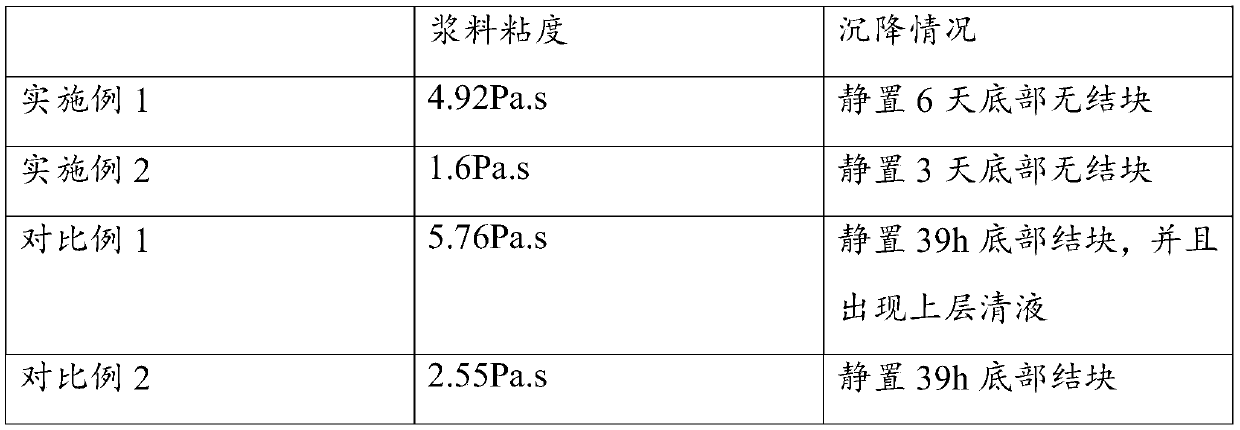

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a preparation method of ceramic light-cured slurry, including:

[0031] Weigh raw materials according to the following weight percentages: 50%-80% of ceramic powder, 0.05%-0.4% of the first dispersant, 18.2%-49.55% of resin and 0.4%-2.4% of the second dispersant;

[0032] modifying the surface of the ceramic powder with the first dispersant to obtain a modified ceramic powder;

[0033] The modified ceramic powder, resin and second dispersant are mixed to obtain.

[0034] In a preferred embodiment of the present invention, the step of modifying the surface of the ceramic powder with the first dispersant to obtain a modified ceramic powder specifically includes:

[0035] The first dispersant is added into the organic solvent, and after mixing well, the ceramic powder is added, ball milled and pre-dried to obtain a modified ceramic powder.

[0036] In the embodiment of the present invention, the specific type of organ...

Embodiment 1

[0045] Measure 160g of absolute ethanol in a beaker, add 0.2g of stearic acid, ultrasonically dissolve, then pour into a ball mill jar, add zirconia grinding medium, then add 200g of alumina ceramic powder, and mill in a ball mill at 240rpm for 3h , dried at 100°C after discharge to make modified ceramic powder;

[0046] Measure 30g propoxylated neopentyl glycol diacrylate in a ball mill jar, then weigh 2.5g BYK111 dispersant, add zirconia grinding medium, then mix evenly, then add 150g modified ceramic powder, and place it in a planetary ball mill , ball milled at 180rpm for 19h, then added 2g of high molecular weight dispersant Solsperse 39000, and then ball milled at 240rpm for 3.5h to obtain the product.

Embodiment 2

[0048] Measure 160g of absolute ethanol in a beaker, add 1g of lauric acid, ultrasonically dissolve it, then pour it into a ball mill jar, add zirconia grinding media, then add 200g of alumina ceramic powder, mill it in a ball mill at 240rpm for 3h, and get out After drying at 100°C, the modified ceramic powder is made;

[0049] Measure 30g of cyclotrimethylolpropane methylal acrylate in a ball mill jar, then weigh 4.6g of Disper655 dispersant, add zirconia grinding medium, then mix evenly, then add 150g of modified ceramic powder, place on planetary In a type ball mill, ball mill at a speed of 180 rpm for 19 hours, then add 1.1 g of high molecular weight dispersant Solsperse 39000, and then ball mill at a speed of 240 rpm for 3.5 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com