Phosphating treatment device for split pin

A processing device and phosphating pool technology, which is applied in the coating process of metal materials, etc., can solve problems such as inconsistent concentration, influence on enterprise production, and uneven phosphating, so as to prevent uneven concentration, facilitate placement and collection, and improve phosphorus concentration. The effect of chemical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

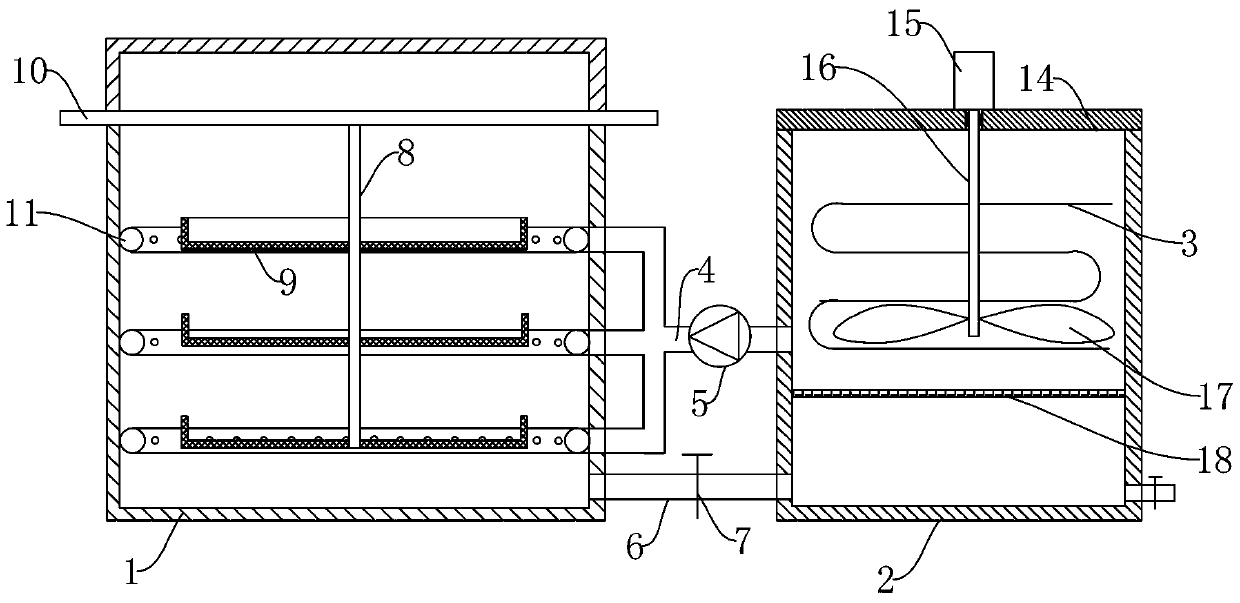

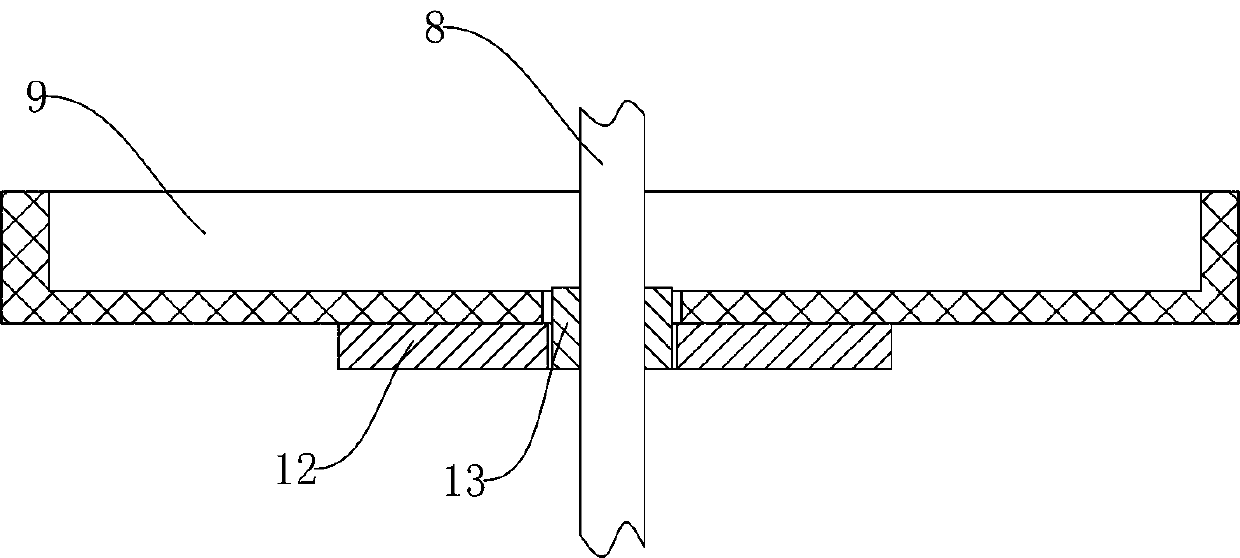

[0010] Such as figure 1 As shown, a cotter pin phosphating treatment device includes a phosphating tank 1 and a liquid storage tank 2, a heating coil 3 is arranged in the liquid storage tank 2, a sewage outlet is provided at the bottom, a valve is provided on the sewage outlet, and the liquid storage tank 2 communicate with the phosphating tank 1 through the liquid inlet pipe 4, the liquid inlet pipe 4 is provided with a water pump 5, the bottom of the phosphating tank 1 is connected with the liquid storage tank 2 through the liquid return pipe 6, and the liquid return pipe 6 is provided with a valve 7, A storage rack is provided in the phosphating tank 1, and the storage rack includes a support rod 8 and several layers of storage boxes 9 arranged on the support rod 8. The storage box 9 is a screen structure, and the storage box 9 is arranged along the height of the support rod 8. The upper end of the support rod 8 is provided with a limiting plate 10 , and the limiting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com