Combined assembled bridge section based on core box body

An assembled and box-based technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor structural integrity and driving comfort, limitations in bridge deck width and landscape, and high construction technical requirements, and achieve overall Beautiful shape, transparent view under the bridge, good landscape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

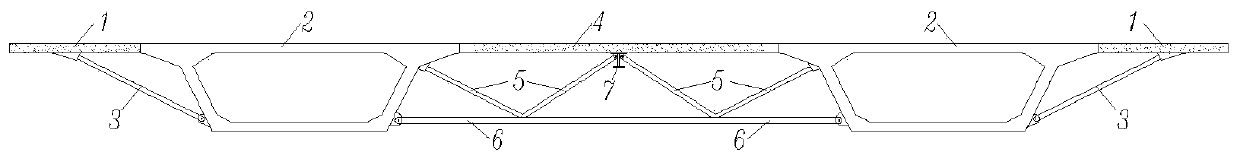

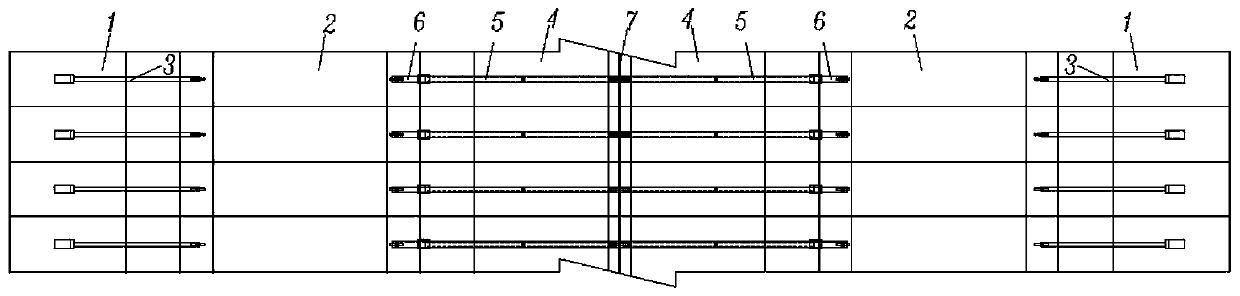

[0022] Attached below Figure 1-5 And the specific embodiment further illustrates the present invention.

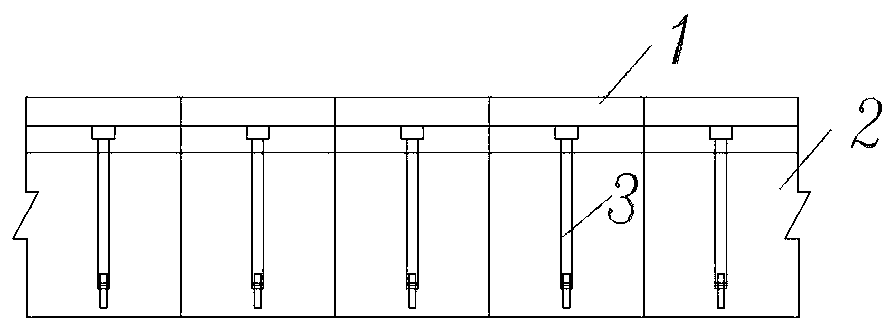

[0023] As shown in Figure 1: a composite assembled bridge section based on the core box, including the core box 2 on the left and right sides, the cast-in-place flange plates 1 on both sides, and the middle part is the cast-in-place bridge deck 4 between the core boxes, Flange diagonal struts 3 under the cantilever of the flange plates 1 on both sides, the cast-in-place bridge deck 4 between the core boxes connecting the two core boxes 2 in the middle, and the steel oblique web bars 5 and lower chords 6 below, the box core 2 is Prefabricated segmental assembly construction, cast-in-place core box 2 flange panels 1 on both sides and cast-in-place bridge deck 4 between core boxes in the middle part, and steel rods are used below the cast-in-place concrete for support. This embodiment is suitable for bridges with a relatively large width. Figure 2 shows the support of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com