Railway turnout snow melting locking frame heating mechanism

A technology of heating mechanism and locking frame, which is applied in track cleaning, construction, cleaning methods, etc., can solve the problems of low thermal efficiency, lack of snow removal, high labor intensity, etc., and achieve strong corrosion resistance, aging resistance, and convenience Installation and maintenance, the effect of increasing the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

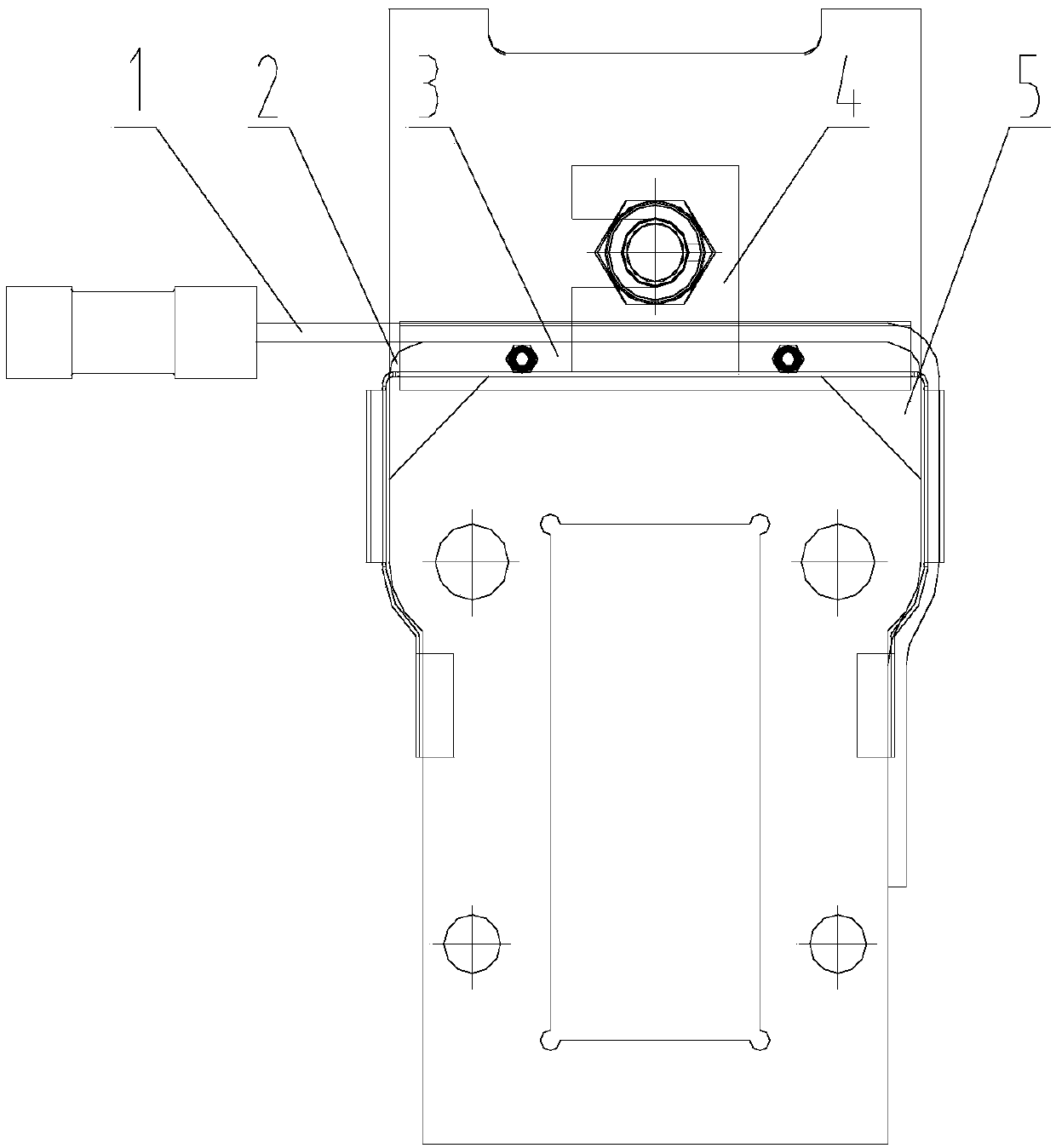

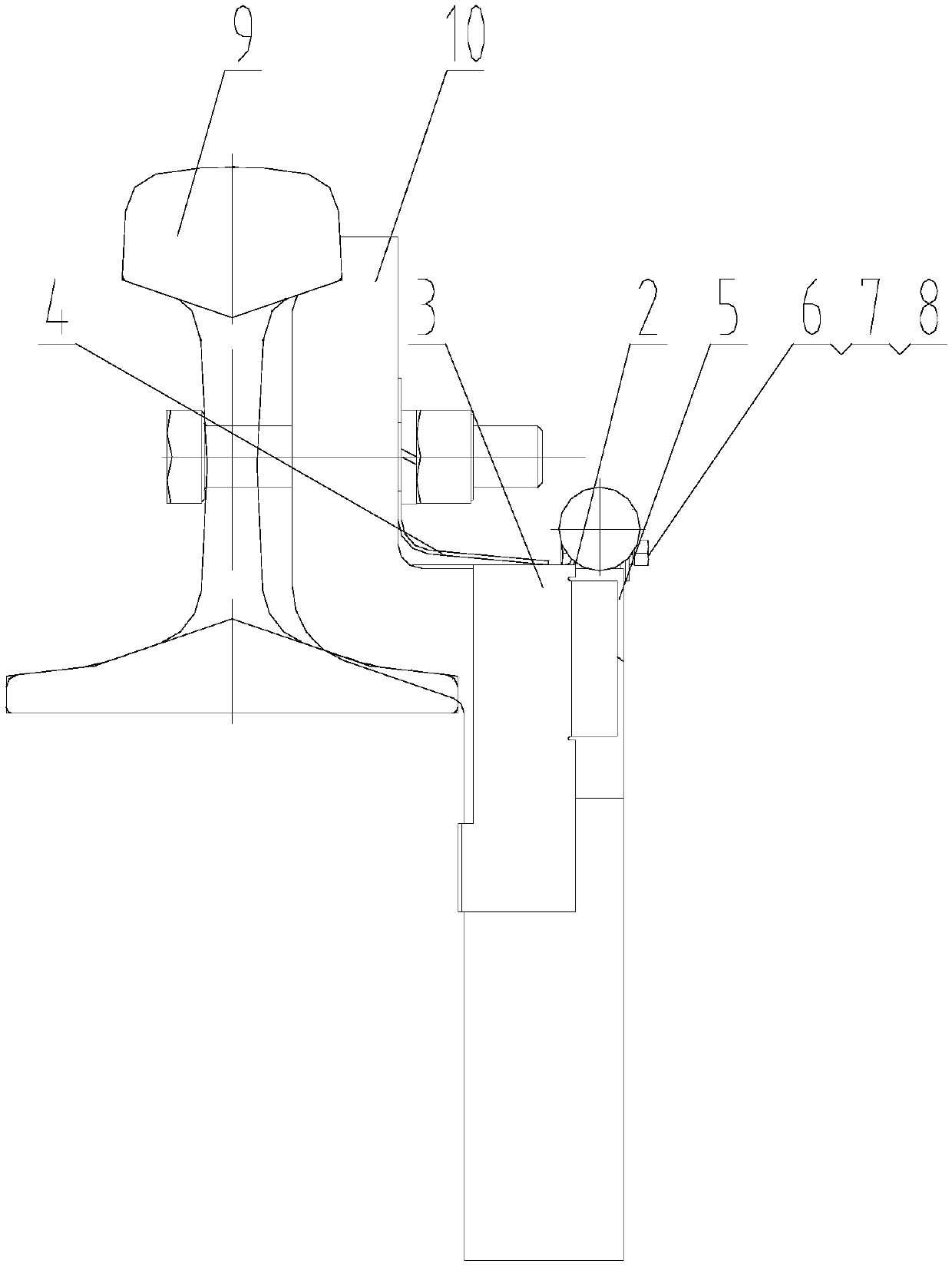

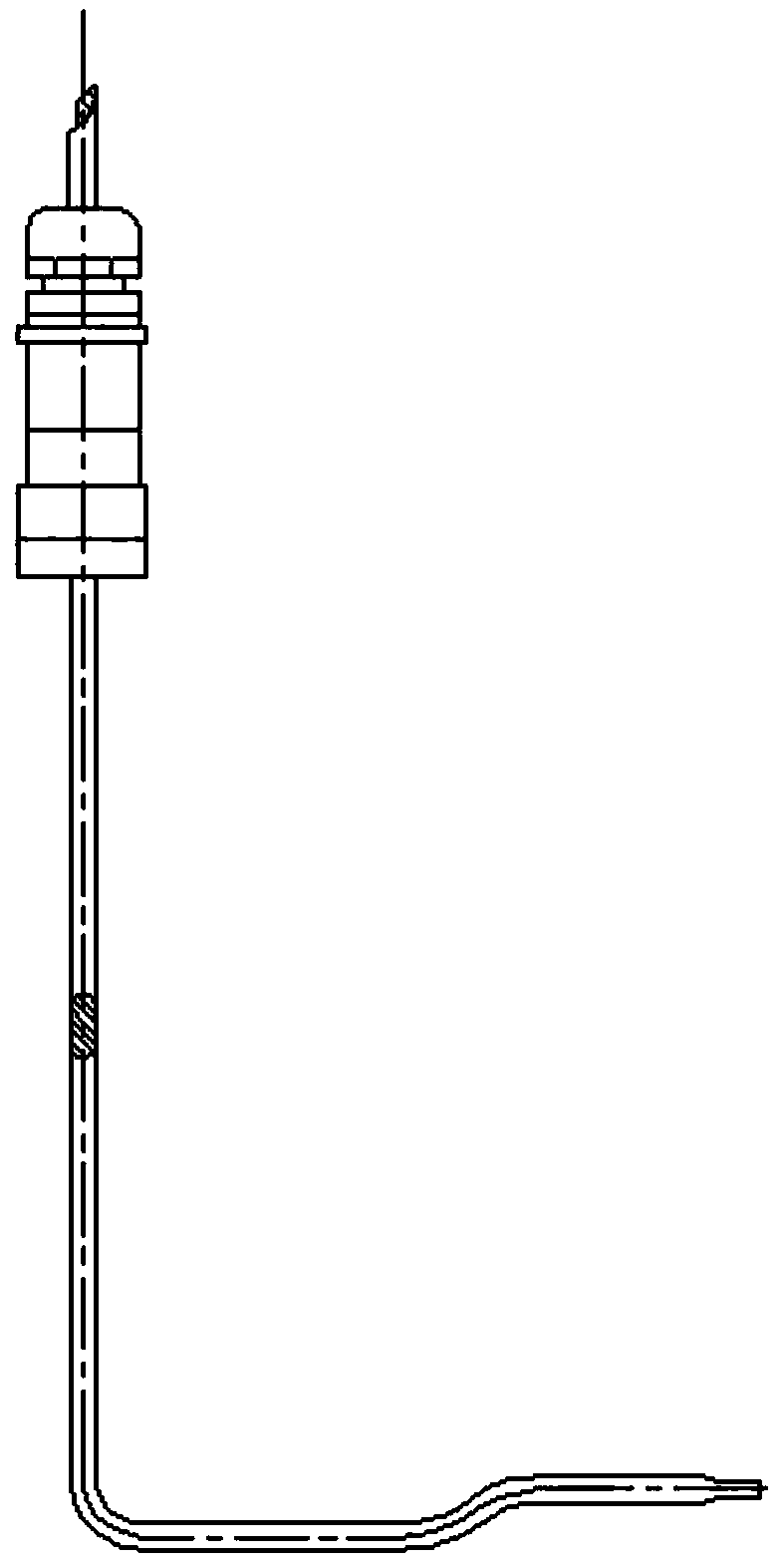

[0023] As shown in Figure 1, the present invention relates to a heating mechanism for a railway turnout snow melting locking frame, which is characterized in that it includes an L-shaped 180W electric heating element 1, an aluminum alloy heat conducting pad 2, an elastic clamp 3, an elastic pressing piece 4, Aluminum alloy triangular filling block 5, fastener group 6-8, railway turnout 9, locking frame 10; the locking frame 10 is connected with the railway turnout 9 through bolts and nuts, and the locking frame 10 has a On the extension table, the elastic fixture 3 is stuck on both sides of the extension table. The elastic fixture 3 is connected with the elastic pressing piece 4 and the aluminum alloy thermal pad 2 at the same time. One end of the elastic pressing piece 4 is fixed on the locking frame 10 and the railway switch 9 In the connected bolts and nuts, the L-shaped 180W electric heating element 1 is connected through the elastic pressing piece 4, and the fastener group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com