Fatigue-resistant impact-resistant pull-off-resistant bidirectional buckling and pressing joint

A technology of fatigue resistance and compression joints, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing components, etc., can solve the problems of insufficient fatigue resistance and impact resistance, imperfect self-locking function, and low connection strength, etc., to achieve Save axial space size, improve pull-out resistance, and ensure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

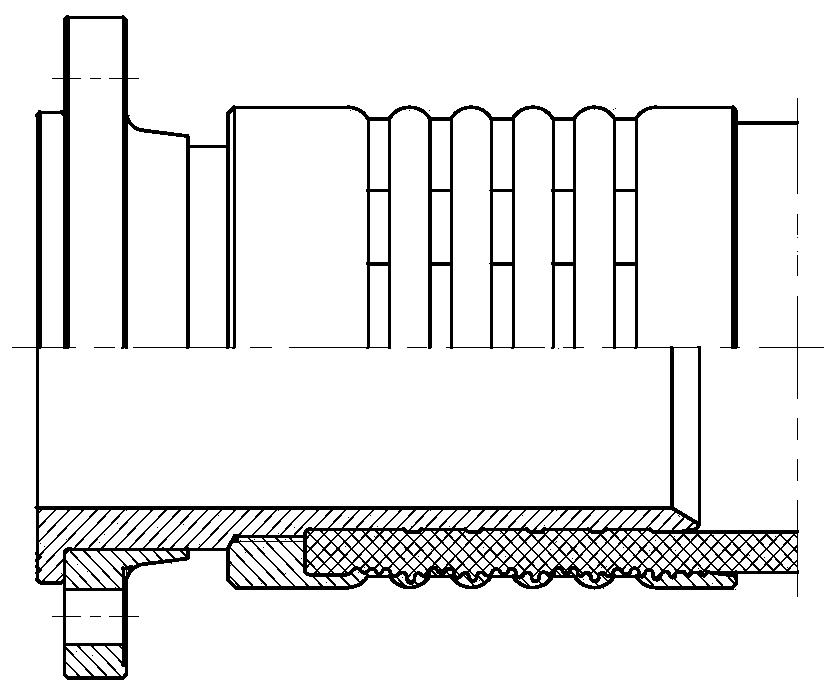

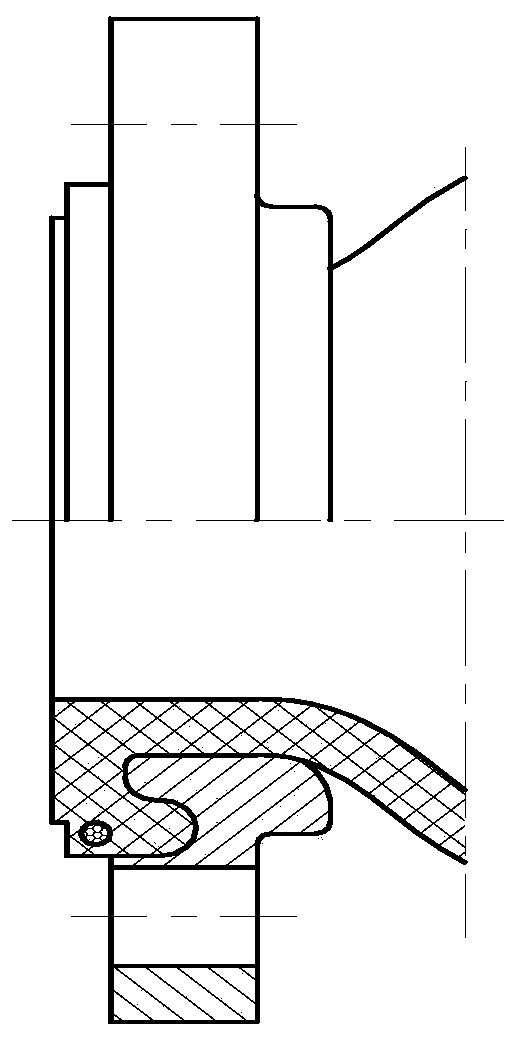

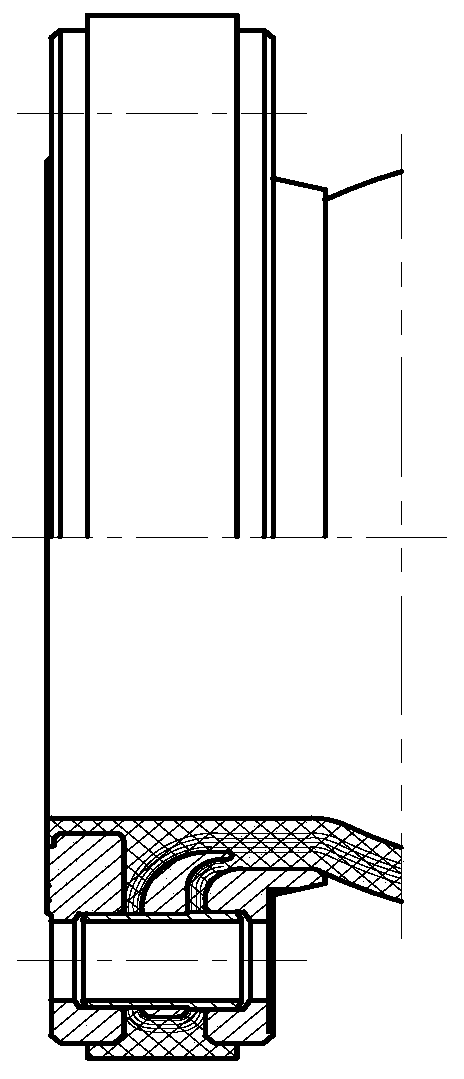

[0047] see Figure 6-10 As shown, a two-way crimp joint with fatigue resistance, impact resistance and pull-out resistance includes a crimp joint, a loose flange, and a flexible pipe body; the crimp joint includes an outer pressure ring and an inner pressure ring; the loose flange It is a flange plate structure, and the flexible pipe body includes an inner rubber layer, a skeleton layer, and an outer rubber layer sequentially from the inside to the outside, the buckle joint is located at the end of the flexible pipe body, the outer pressure ring, the inner The pressure ring is an annular sleeve structure, the outer pressure ring is overlaid on the inner rubber layer at the end of the flexible pipe body, and the annular depression provided at the end of the inner ring of the outer pressure ring is in contact with the end of the inner rubber layer. The ring-shaped boss set outside is fitted together to form a sealing structure between the buckle joint and the conveying medium in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com