Repair method of the prefabricated module at the bottom of the suspended cylinder of Maerz lime kiln

A repair method and technology of hanging cylinders, applied in the direction of lining repair, furnace control devices, furnaces, etc., can solve the problems of hanging refractory material falling off the outer wall of the hanging cylinder, unsatisfactory use effect, and falling off of prefabricated modules, so as to increase thermal shock stability, The effect of increasing strength and avoiding production stop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

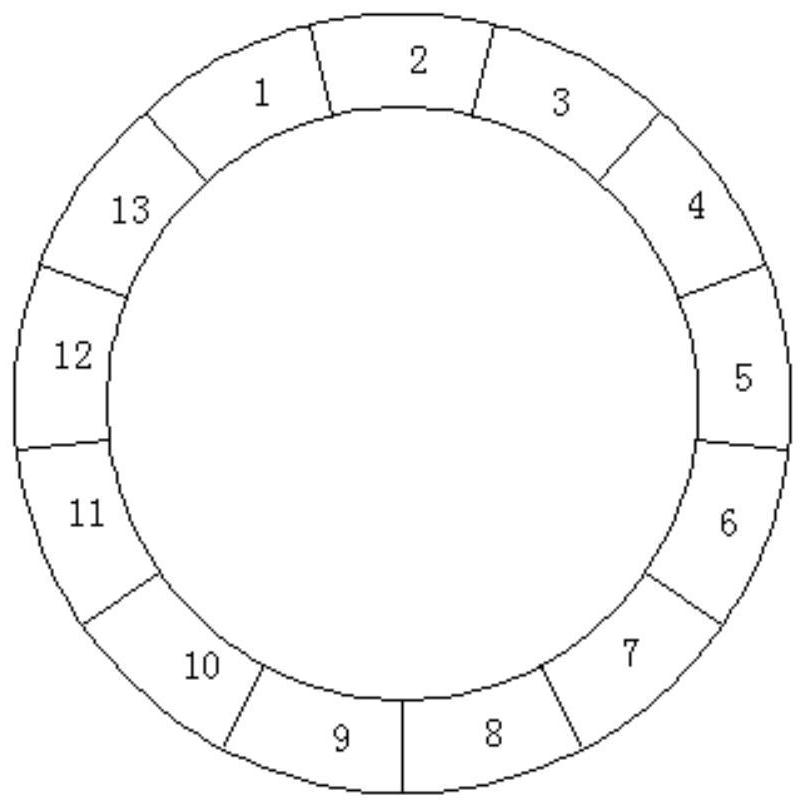

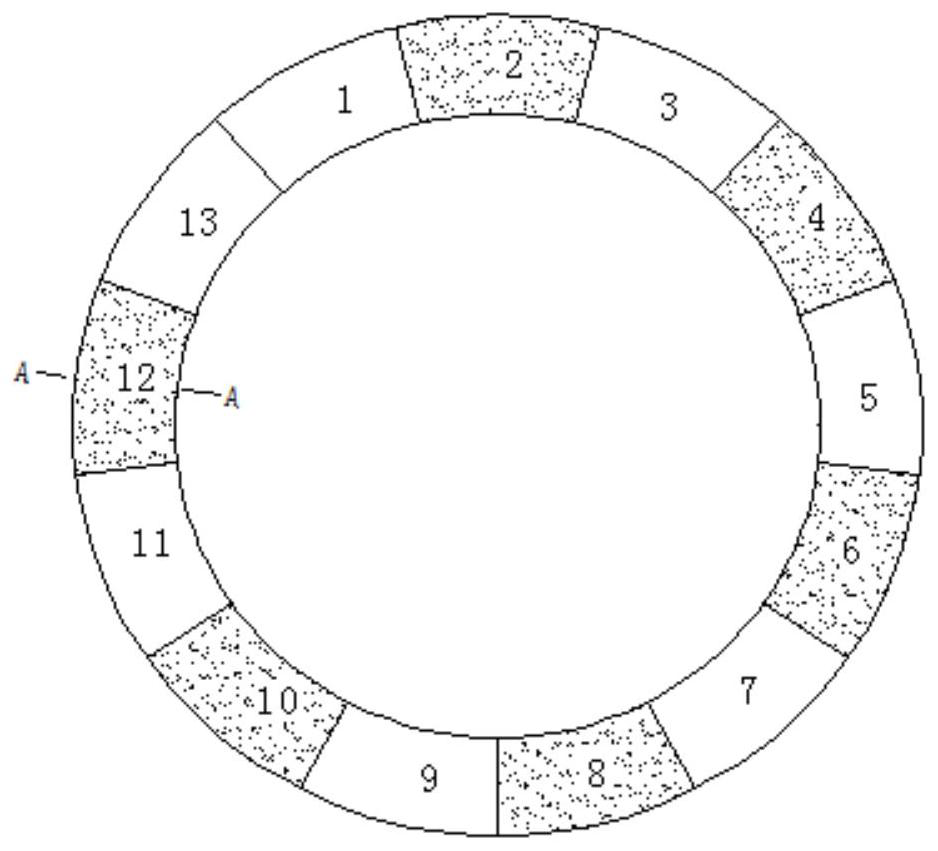

[0038] This embodiment provides a method for repairing the prefabricated module at the bottom of the hanging cylinder of the Maerz lime kiln, wherein the prefabricated module at the bottom of the hanging cylinder of the Maerz lime kiln is a prefabricated module imported from abroad, and there are 52 pieces in total. The repair method provided in this embodiment In the first step, 52 prefabricated modules are divided into 13 unit blocks according to 4 prefabricated modules as a unit block, such as figure 1 As shown, the 13 unit blocks are respectively named as unit block 1, unit block 2, unit block 3, unit block 4, unit block 5, unit block 6, unit block 7, unit block 8, unit block 9, and unit block 10 , unit plate 11, unit plate 12, unit plate 13; the repair method that this embodiment provides specifically comprises the following steps:

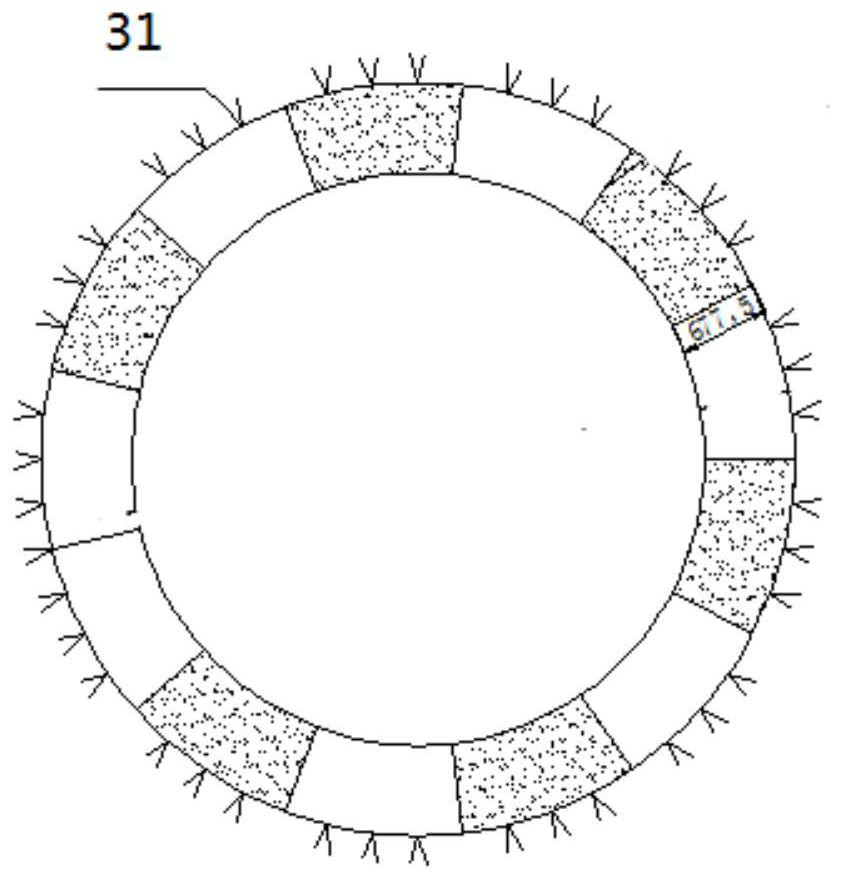

[0039] 1) Remove the imported prefabricated modules of the damaged unit plates 2, 4, 6, 8, 10 and 12 at the bottom of the suspension cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com