Method for improving temperature and humidity control precision of storage battery plate curing chamber

A plate solidification and humidity control technology, applied in non-electric variable control, control/adjustment system, and simultaneous control of multiple variables, etc., can solve the problem that the controlled temperature and humidity are easy to overshoot, affect the quality of the plate, and have poor adaptability, etc. problems, to achieve the effects of small overshoot, meeting consistency requirements, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

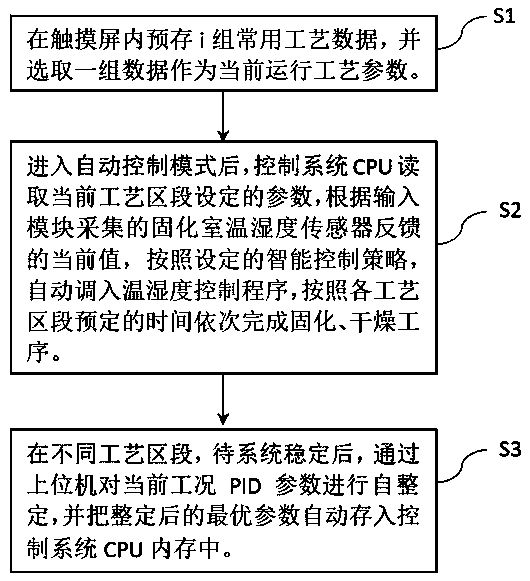

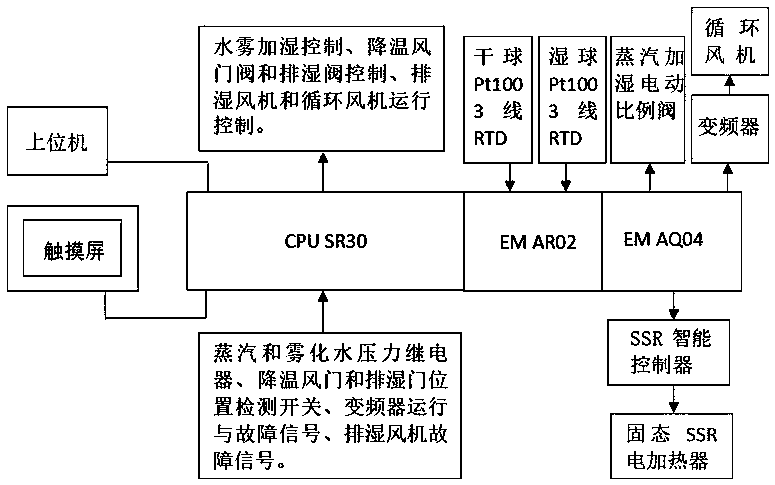

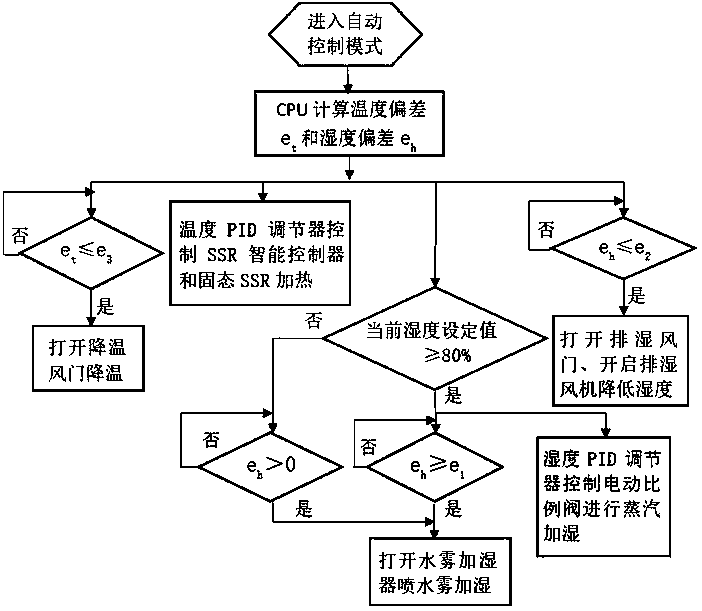

[0019] The battery plate curing process generally adopts a staged curing method. According to the basic situation of PbO oxidation in the plate curing, the curing is divided into several stages: the first stage is controlled within 15h. In this stage, a large amount of PbO is oxidized. Curing at low temperature and high humidity, followed by curing at high temperature and high humidity; the second stage is 8-10 hours, directly curing at medium temperature, and appropriately reducing relative humidity; the third stage is 10-15 hours, curing at medium temperature, and then lowering it appropriately Relative humidity; the fourth stage is 24-30h, which is a dry stage, and the relative humidity is kept low. Since the temperature and humidity setting values in the four stages are different, especially the humidity setting value changes gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com