Simulation method for assisting in design and inspection of lead-acid battery based on electrochemical principle

A lead-acid battery and simulation method technology, applied in electrochemical generators, fuel cells, fuel cell additives, etc., can solve the problems of wasting computing resources and high computing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

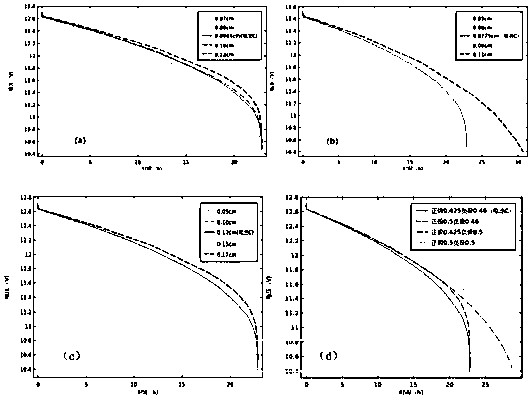

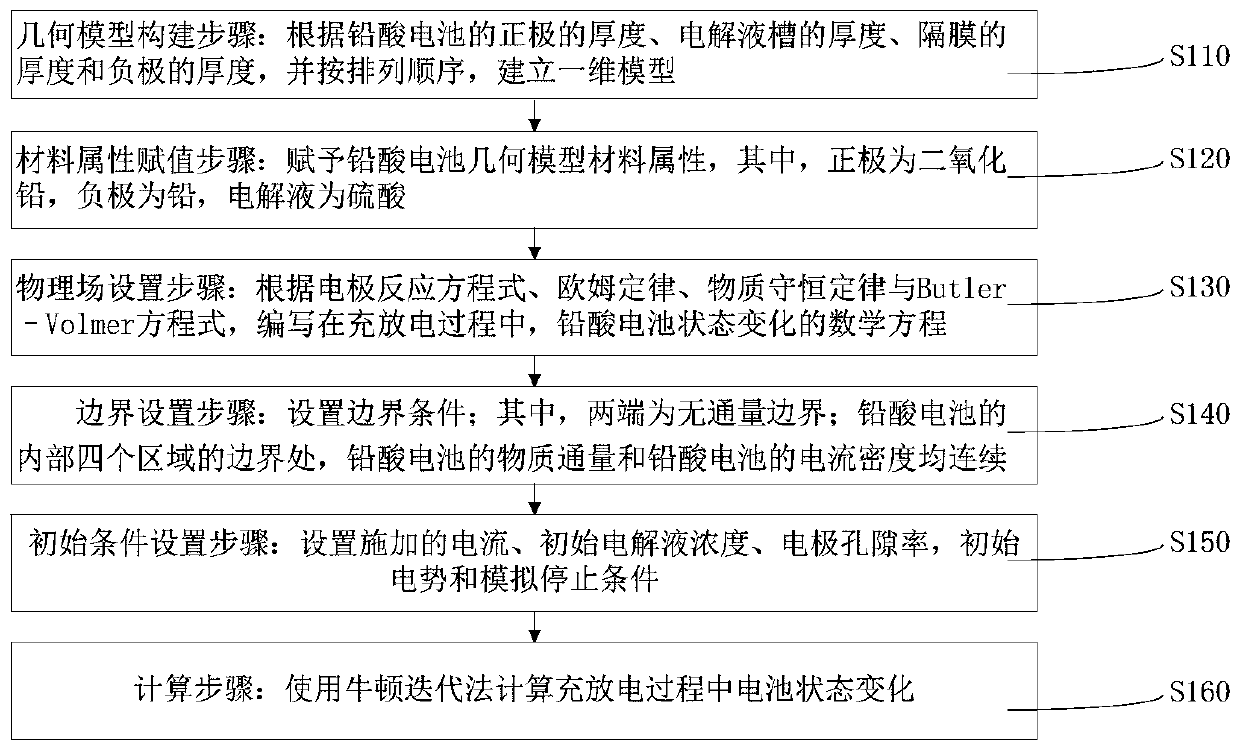

[0280] A simulation method for the design and inspection of auxiliary lead-acid batteries based on electrochemical principles, taking the capacity test of a flooded L2 lead-acid battery with a rated capacity of 60Ah (3A constant current discharge at 25°C to a voltage of 10.5V) as an example , including the following steps:

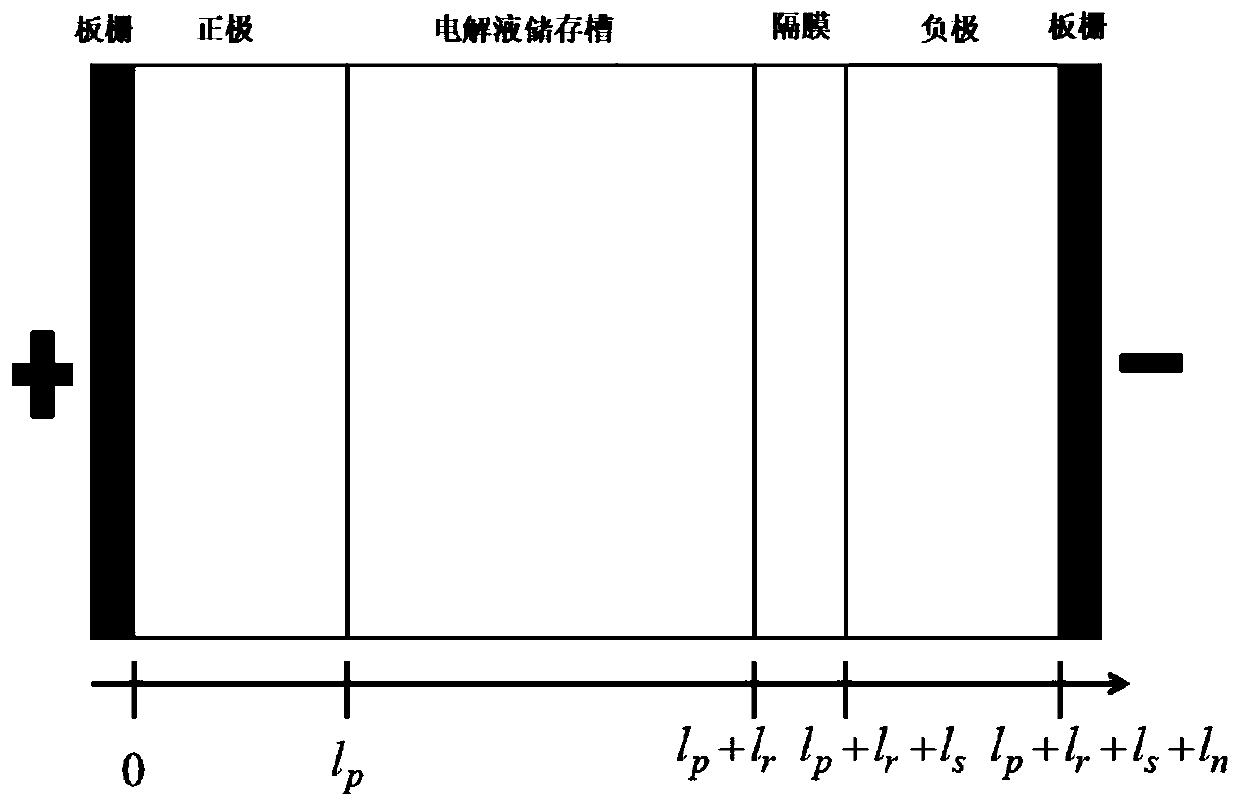

[0281] 1) Geometric model construction: such as Figure 7 According to the design parameters of the L2 type lead-acid battery, the thickness of the positive electrode is 0.0445cm, the thickness of the electrolyte tank is 0.32cm, the thickness of the diaphragm is 0.025cm, and the thickness of the negative electrode is 0.0434cm, and the one-dimensional model is established in sequence;

[0282] 2) Assignment of material properties: according to the composition of the battery, the material properties of the geometric model are assigned, and the positive electrode is PbO 2 , the conductivity is 80S / cm, the negative plate is Pb, and the conductivity is 47000S / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com