A permanent magnet type magnetic screw

A magnetic screw and permanent magnet technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problems of large amount of materials, complex assembly structure, etc., and achieve the effects of not easy demagnetization, simplified installation process, and large coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

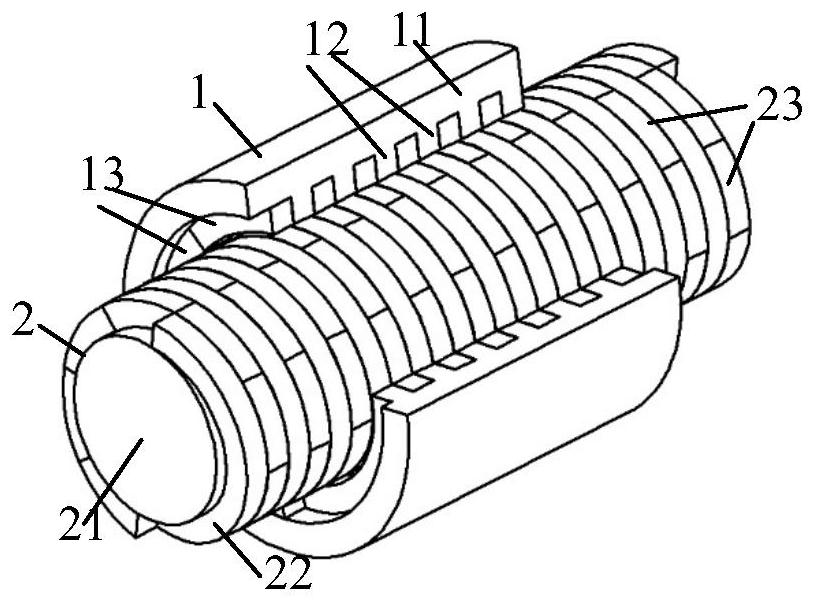

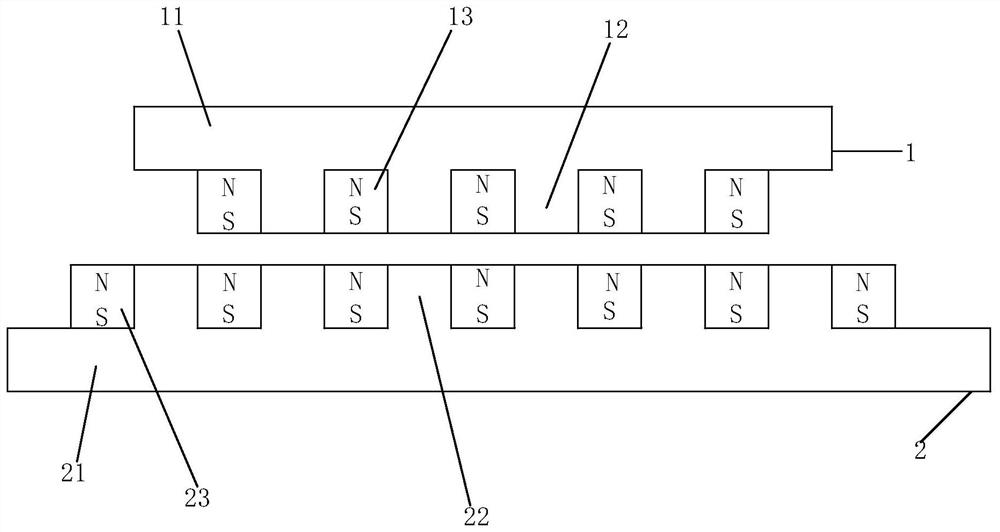

[0018] The permanent magnet type magnetic screw rod proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0019] The core idea of the present invention is that the permanent magnet type magnetic screw provided by the present invention reduces the amount of magnetic materials, and has the advantages of automatic overload protection, small friction loss and high reliability of the traditional magnetic screw. The permanent magnet type magnetic screw rod provided by the present invention can convert the linear motion with high thrust and low linear velocity into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com