Design product structure and method for manufacturing 5G circuit board

A circuit board manufacturing and design method technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit, etc., can solve problems such as pressing bonding force and lack of signal conductivity of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

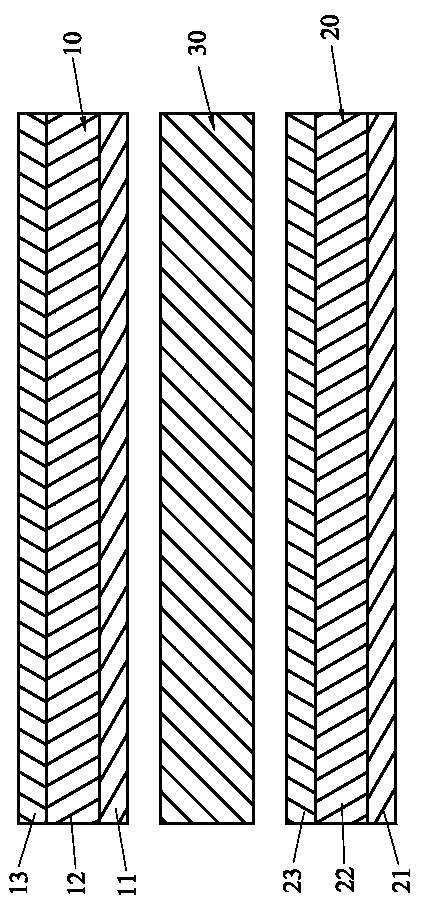

[0026] The present invention discloses a design product structure for 5G circuit board manufacturing, such as image 3 As shown, it includes an upper core board 10 , a lower core board 20 and a connection curing sheet 30 .

[0027] The upper core board 10 includes a first lower copper foil layer 11, a first cured sheet 12, and a first upper copper foil layer 13 that are laminated and fixed together from bottom to top; the lower core board 20 includes a bottom-up The second lower copper foil layer 21, the second cured sheet 22, and the second upper copper foil layer 23 are stacked and fixed together; the connected cured sheet 30 is sandwiched between the upper core board 10 and the lower core board 20, and the second Both the lower copper foil layer 11 and the second upper copper foil layer 23 are reversed copper foils, and are attached and fixed to the upper and lower surfaces of the connection curing sheet 30 respectively.

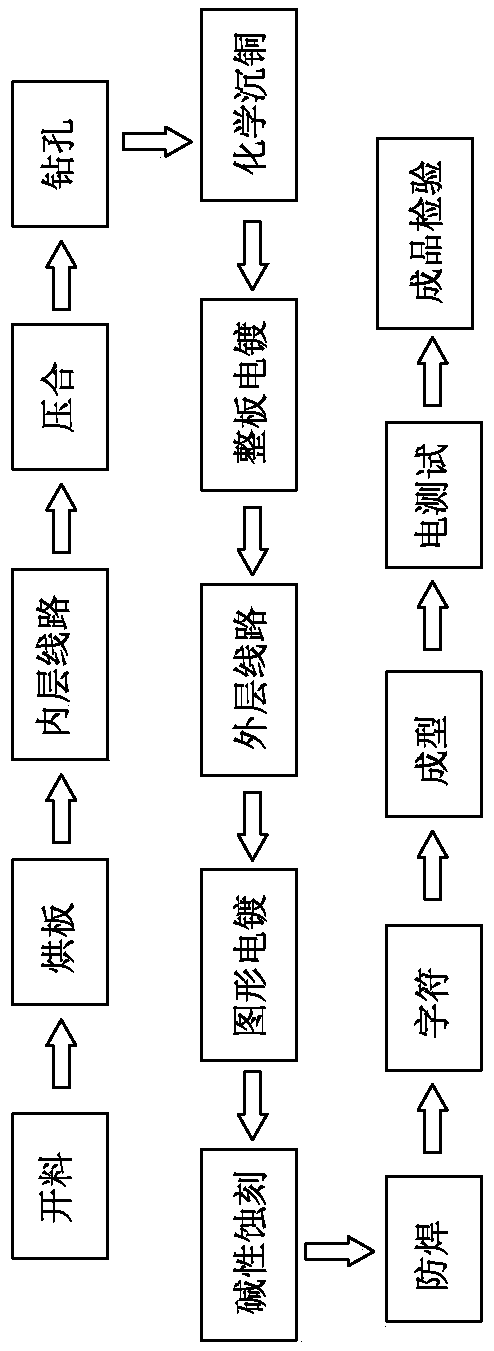

[0028] Such as figure 1 As shown, the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com