Flux-cored wire for submerged arc welding, and material for submerged arc welding

A technology of submerged arc welding and welding wire, which is applied in welding/cutting medium/material, welding medium, welding equipment, etc. It can solve the problems of unclear low temperature toughness and difficulty in ensuring impact performance, and achieve excellent low temperature toughness, high strength, and excellent welding. operational effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

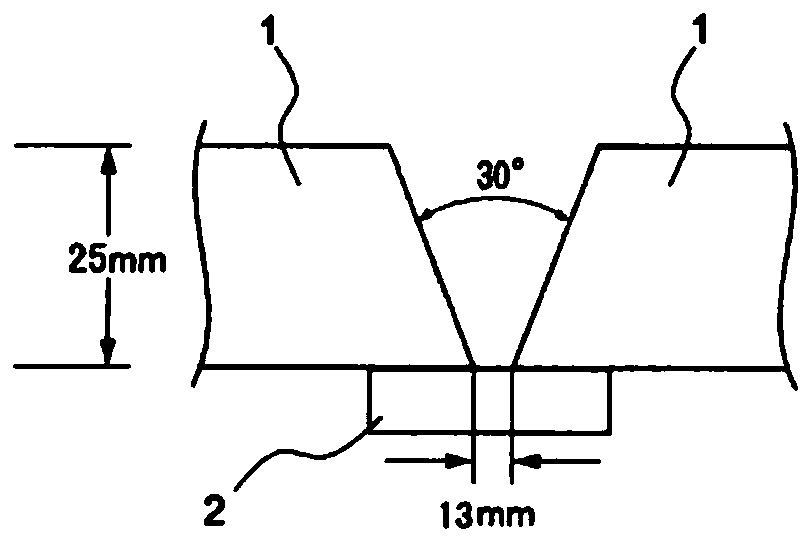

Image

Examples

Embodiment

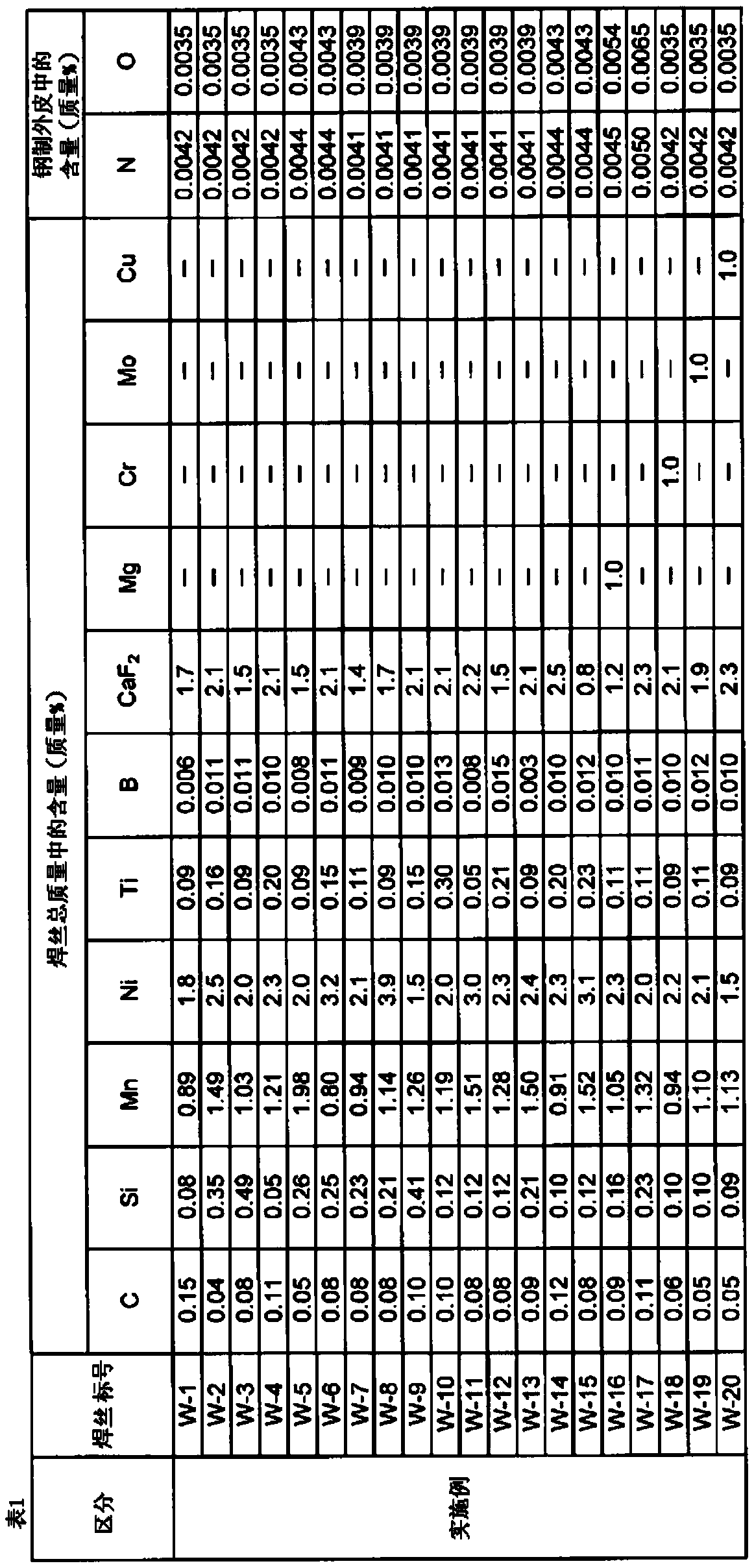

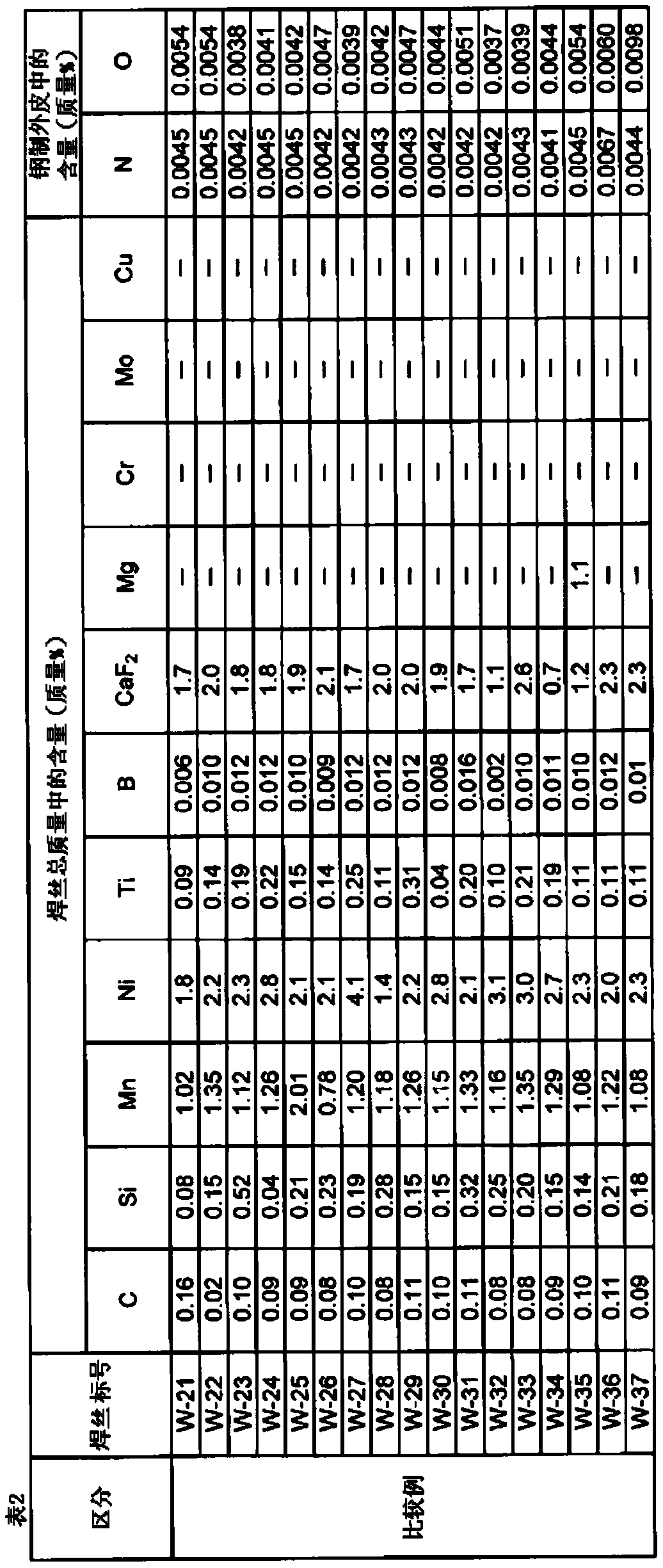

[0069] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in more detail, this invention is not limited to this.

[0070] In Table 1 and Table 2 below, the chemical composition (% by mass) of the flux-cored wire used in this test is shown. Also, in the chemical component composition in the total mass of the welding wire, the balance is Fe and unavoidable impurities. In addition, "-" in each component amount of Mg, Cr, Mo, and Cu means that each component amount is an amount equal to or less than the impurity level. In addition, the respective component amounts of N and O are the contents in the steel sheath (in the total mass of the steel sheath).

[0071] In addition, in the following Table 3, the chemical component composition (mass %) of the sintered-type flux (combined sintered-type flux) used for this test is shown. In addition, the basicity (BA) of the sintered type flux is calculated by the following formula (1). H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com