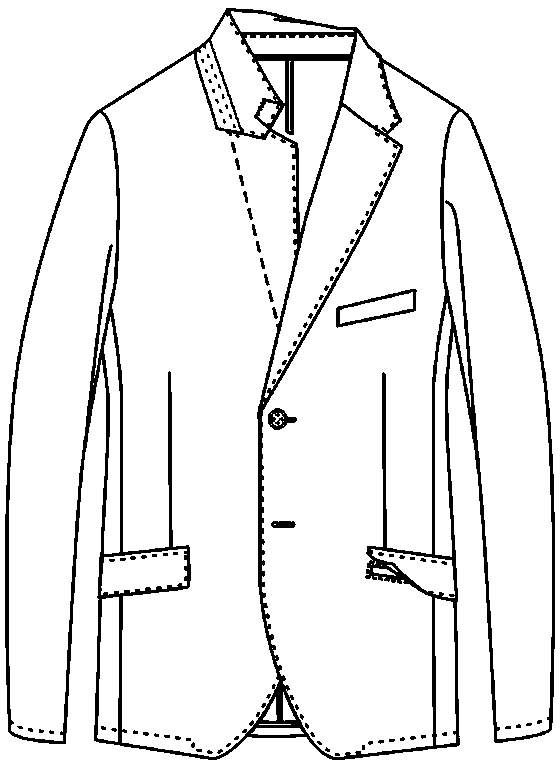

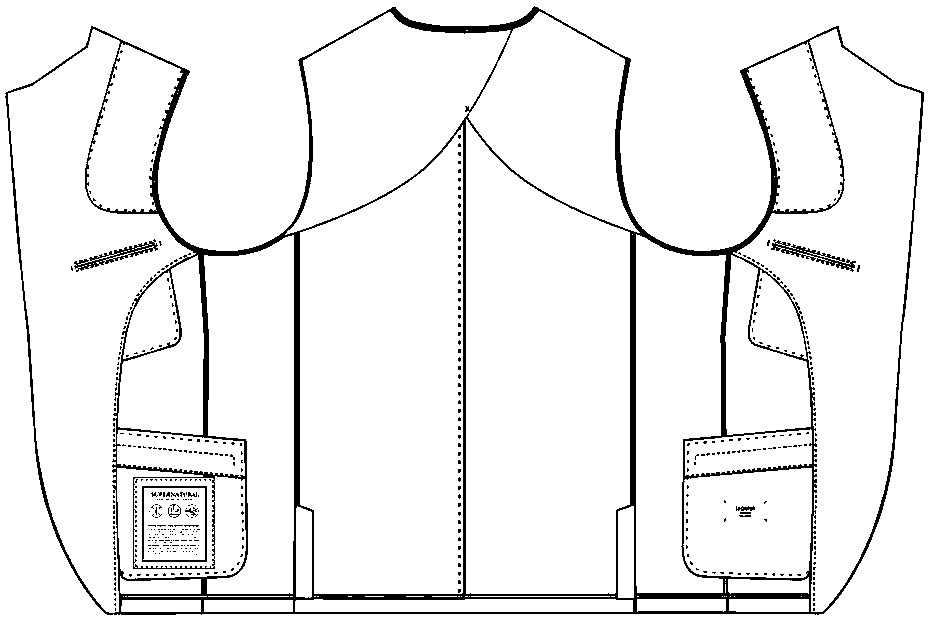

Manufacturing process of portable elastic single suit easy to manage

A production process and portable technology, applied in the direction of clothing, clothing, jackets, etc., can solve the problems of destroying the characteristics of the fabric, difficult to manage, and difficult to coordinate and unify the elasticity, and achieve the effect of high comfortable feel, easy to carry, and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A manufacturing process of a portable and easy-care elastic single suit, comprising the following steps:

[0031] (1) System design: study the improvement points of raw materials, design, structure, process and related manufacturing links;

[0032] (2) Fiber selection: choose high-woven, high-viscosity spandex covered yarn, which is composed of polyester fiber, viscose fiber and spandex. The ratio of polyester fiber, viscose fiber and spandex is 83.6:9.7:6.7, which makes the finished fabric have elasticity and delicate touch.

[0033] (3) Weaving of raw materials: It is made of high-density 42-needle knitting machinery; it is guaranteed to achieve the effect of fine imitation of pure natural fabrics and fabric skeleton. The grey fabric-dyed weaving process prepares the first base color for printing and dyeing, and increases the layering of the finished color.

[0034] (4) Printing and dyeing of raw materials: using high-precision high-speed digital printing and dyeing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com