Reaction device for Suzuki coupling reaction

A technology of reaction device and coupling reaction, applied in the direction of feeding device, chemical/physical/physicochemical fixed reactor, chemical instrument and method, etc., can solve incomplete reaction, insufficient stirring, double-layer glass reactor Does not have the problem of solid-liquid separation function, etc., to achieve the effect of improving production efficiency, improving mixing uniformity, and obvious environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

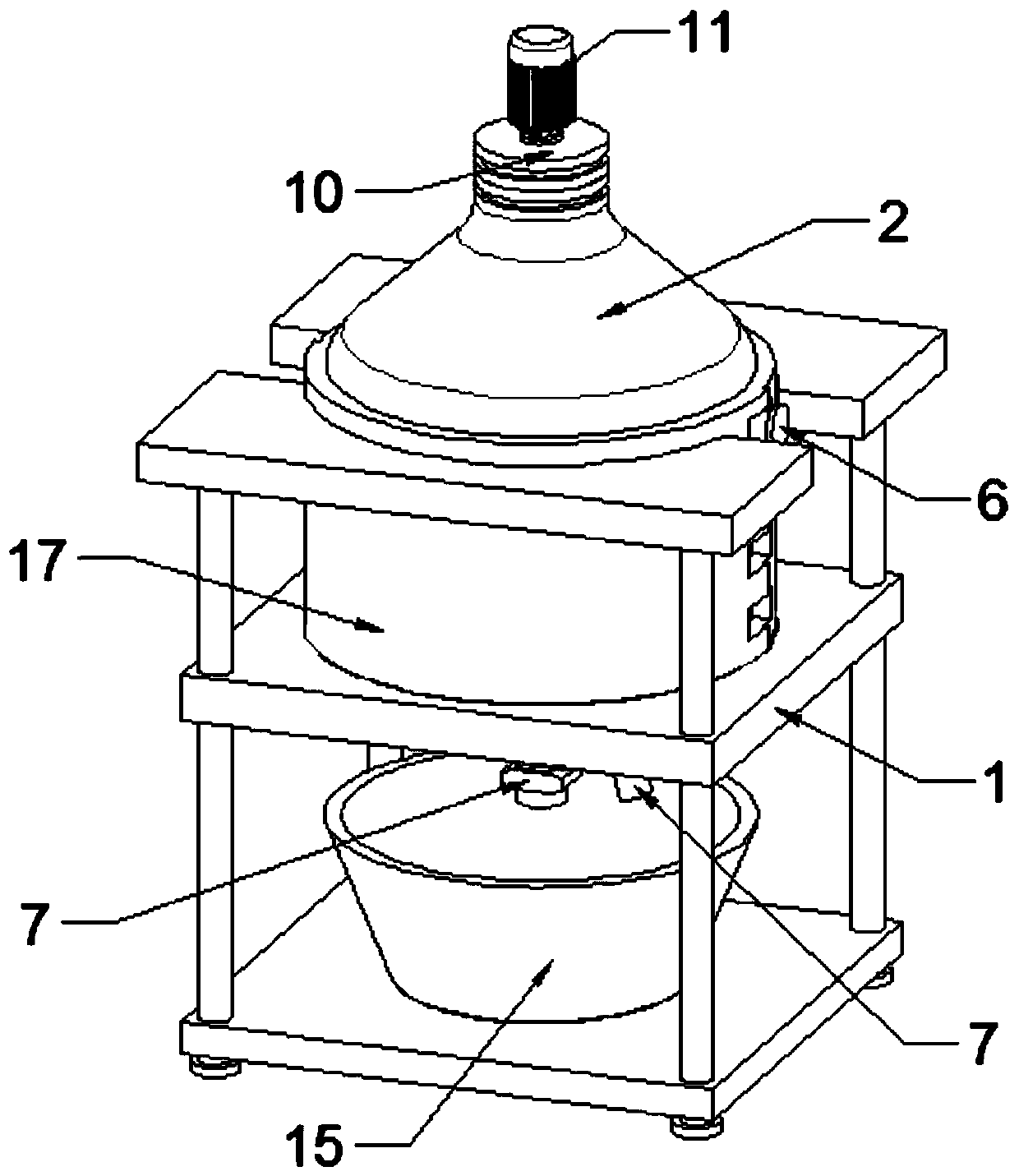

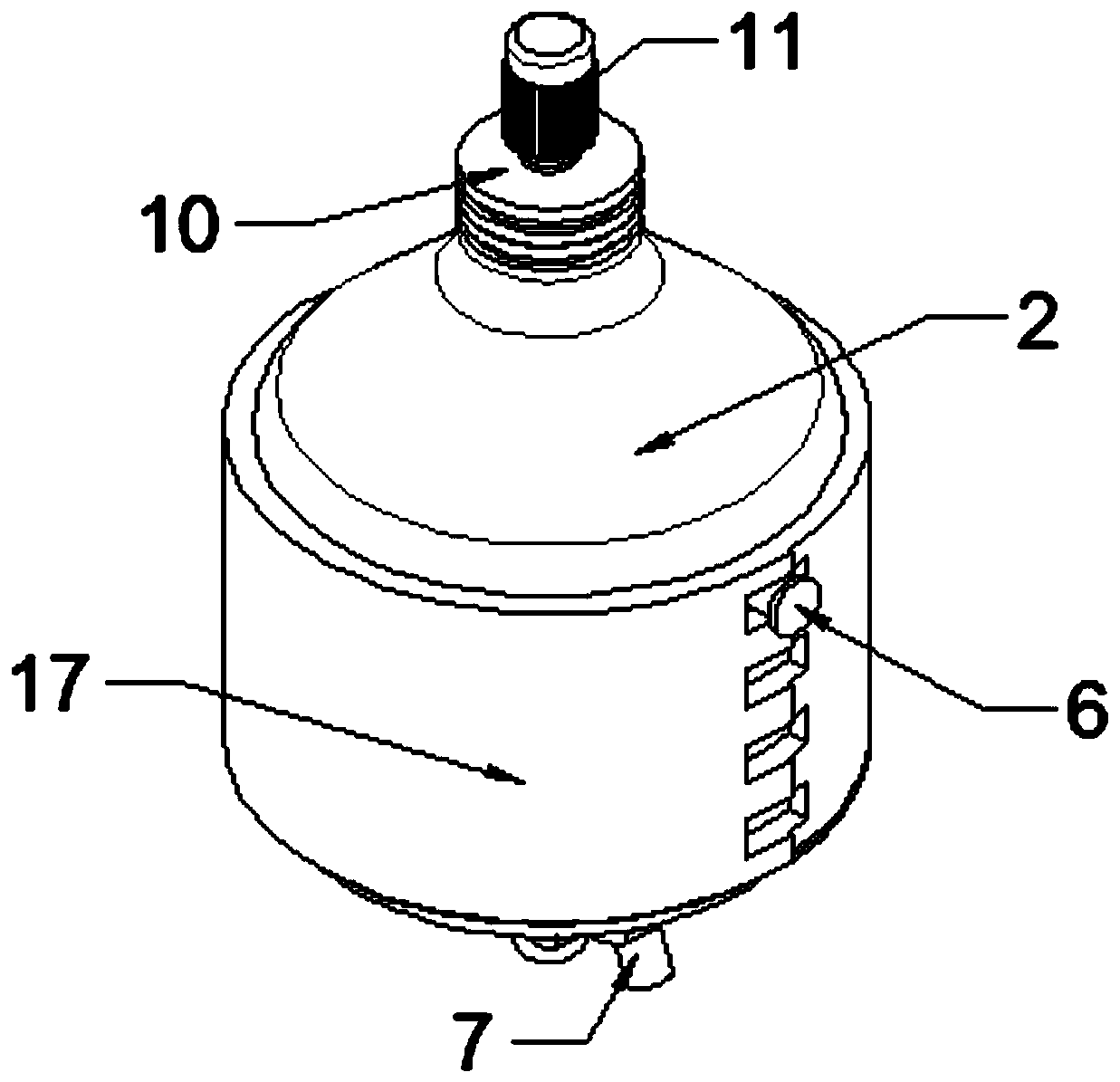

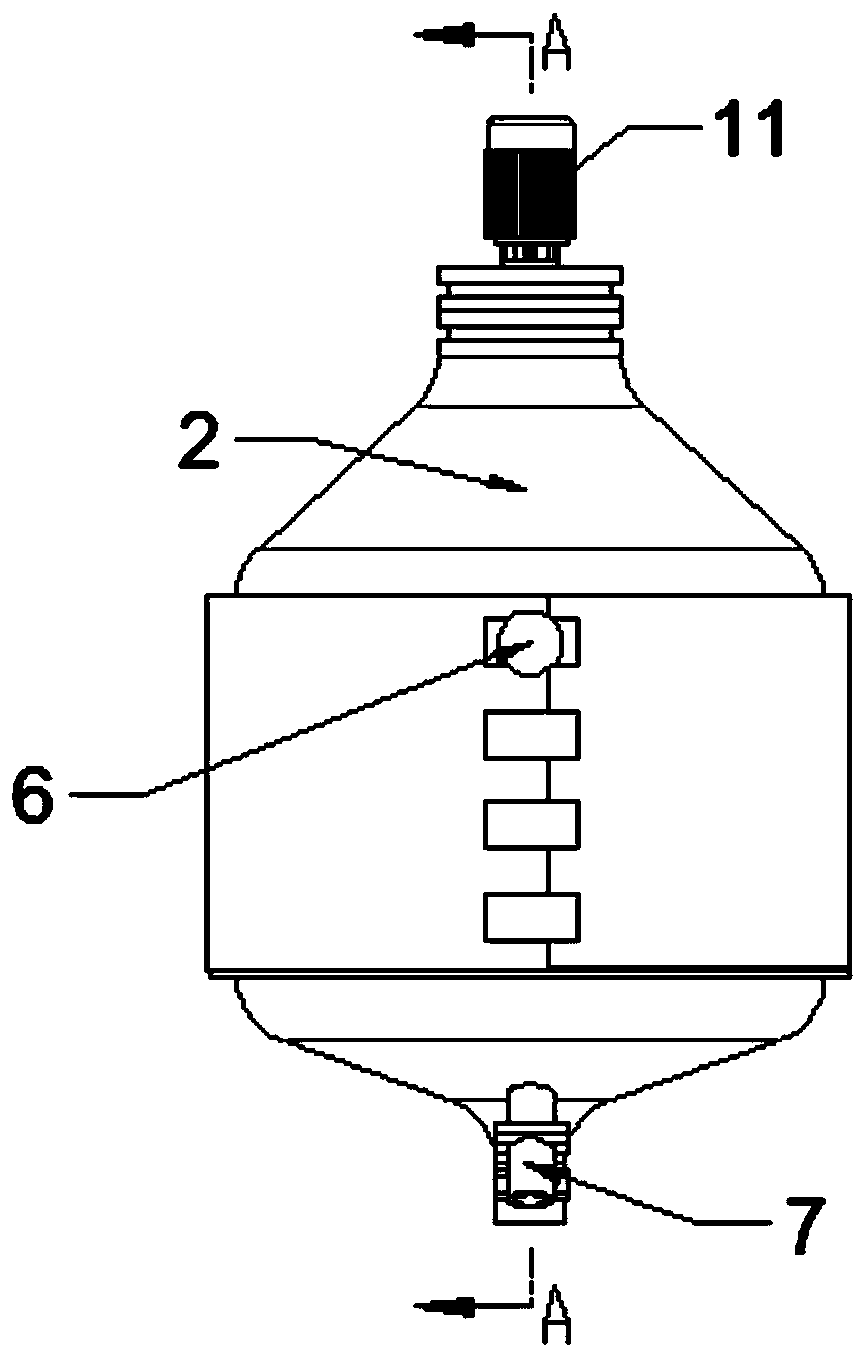

[0032] Such as Figure 1-Figure 7 Shown, a kind of reaction device that is used for Suzuki coupling reaction comprises support frame 1, the reaction kettle body 2 that is installed on the support frame 1 and the liner 3 that is located in the reaction kettle body 2, described liner 3 and The reactor body 2 is provided with a hollow cavity 4, the bottom of the reactor body 2 is provided with a liquid inlet 5 communicating with the hollow cavity 4, and the side of the reactor body 2 top is provided with a liquid inlet 5 connected with the hollow cavity 4. Through the liquid outlet 6, in the interlayer between the reactor body 2 and the inner tank 3, heating or freezing is adopted to make the material react more fully and complete the entire production process. The bottom of the inner tank 3 At least two outlets 7 are provided, wherein one end of the outlet 7 near the inner tank 3 is provided with a filter screen 8, the reaction process and the separation process are coupled in o...

Embodiment 2

[0039] Embodiment 2: as Figure 1-Figure 7 shown

[0040] At present, the inner liner of the double-layer glass reactor produced by many domestic production enterprises is smooth, which results in low mixing uniformity of the material. The original glass inner liner is smooth, and it is easy to produce synchronous rotation of the material and the stirring paddle during mechanical stirring. The efficiency is low, because the inner tank is smooth, the materials are not subject to resistance, and the materials react slowly with each other. Therefore, there is an urgent need for an improved technology to solve the problems in the prior art.

[0041] The spoiler baffle assembly 9 includes a first set of spoiler baffles 901 and a second set of spoiler baffles 902 , and the first set of spoiler baffles 901 and the second set of spoiler baffles 902 are arranged alternately up and down.

Embodiment 3

[0042] Embodiment 3: as Figure 1-Figure 7 shown

[0043]The agitator is usually inserted vertically into the kettle from the center of the top of the kettle, the strength of the top of the kettle is low, and the stirring stability is very poor.

[0044] A supporting seat assembly 14 is arranged on the inner wall of the inner container 3, and the top end of the supporting seat assembly 14 is in conflict with one end of the stirring shaft 13. By setting the supporting seat assembly 14 at the bottom of the inner container 3, the stability of the stirring device is improved.

[0045] In this embodiment, the support seat assembly 14 includes support feet 141 integrally formed on the inner container 3, the support feet 141 are distributed along the side of the outlet 7 of the center line of the inner container 3, and the support feet 141 A supporting block 142 is arranged on the top of the foot 141 , and the stirring shaft 13 is arranged on the supporting block 142 , and the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com