Slow-release concrete water-retaining agent and preparation method thereof

A slow-release concrete technology, applied in the preparation of the slow-release concrete water-retaining agent, in the field of slow-release concrete water-retaining agent, can solve problems such as simple preparation process, achieve good cohesion, avoid phase separation, increase Effects of large hydraulic volumes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

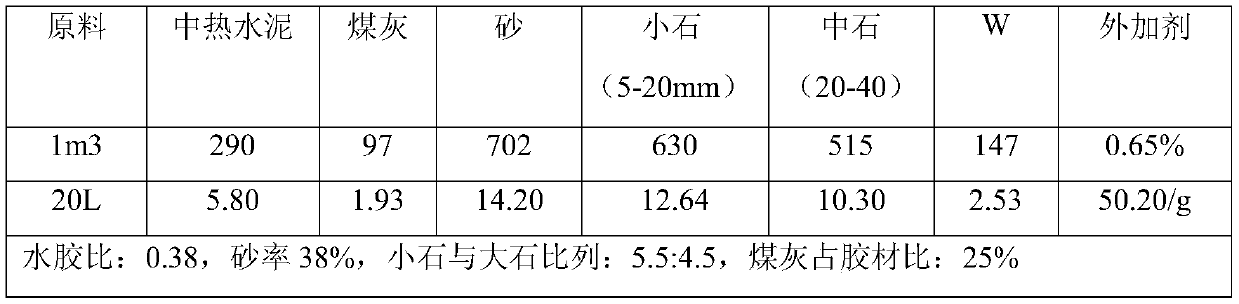

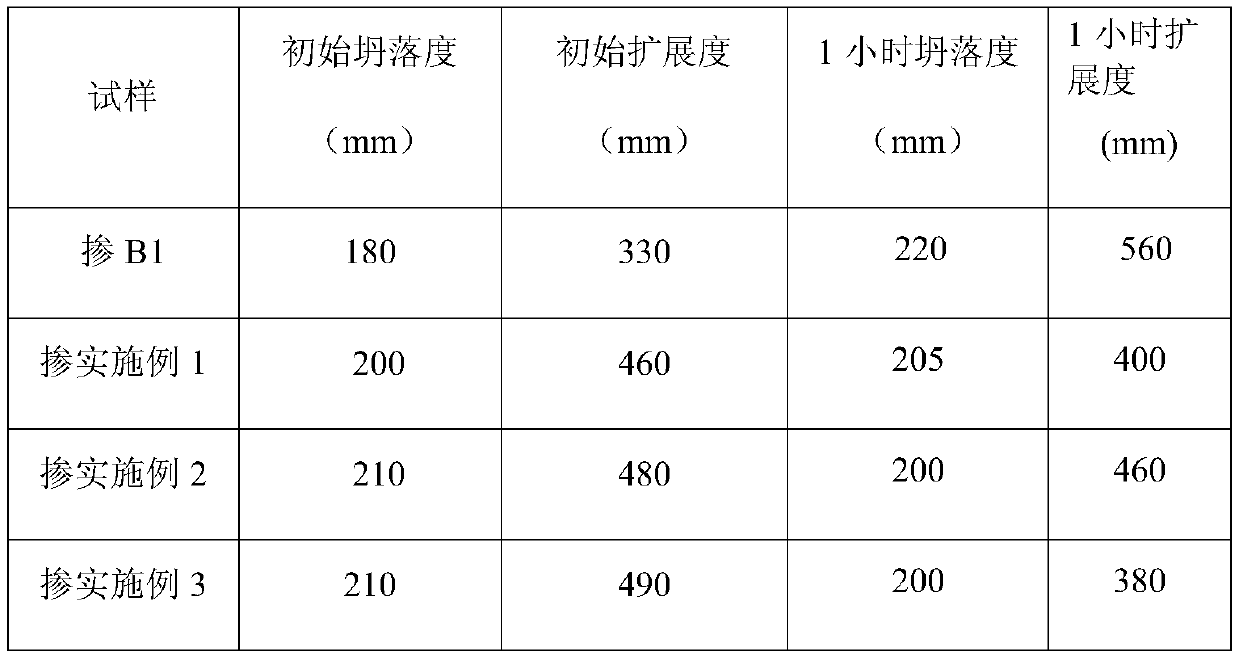

Embodiment 1

[0018] Embodiment 1: The slow-release concrete water-retaining agent of the present invention is made of the following components and raw materials in parts by weight: 31 parts of acrylamide monomers, slow-release monomers, namely hydroxyethyl methacrylate 16.2 parts of ester, 0.2 part of azobisisobutyronitrile as initiator, and 3100 parts of deionized water. The acrylamide monomer is a combination of 30 parts of acrylamide and 1 part of 2-acrylamide-2-methylpropanesulfonic acid. The preparation method of the slow-release concrete water-retaining agent includes the following process steps: ① Dissolve the acrylamide monomer and the slow-release monomer in 220 parts of deionized water according to the above-mentioned parts by mass, and pour the solution into a three-necked flask In the process, start stirring, heat up to 65°C, then add an initiator in a three-necked flask, (at 65°C) heat preservation reaction for 10 hours, add deionized water to dilute, and obtain a colorless an...

Embodiment 2

[0019] Embodiment 2: The slow-release concrete water-retaining agent of the present invention is made of the following components and raw materials in parts by weight: 31 parts of acrylamide monomers, slow-release monomers, namely hydroxypropyl methacrylate 20 parts of ester, 0.18 parts of azobisisobutylimidazoline hydrochloride as initiator, and 3400 parts of deionized water. The acrylamide monomer is a combination of 30 parts of acrylamide and 1 part of 2-acrylamide-2-methylpropanesulfonic acid. The preparation method of the slow-release concrete water-retaining agent includes the following process steps: ① Dissolve the acrylamide monomer and the slow-release monomer in 250 parts of deionized water according to the above-mentioned parts by mass, and pour the solution into a three-necked flask In the process, start stirring, heat up to 55°C, then add an initiator in a three-necked flask, (at 55°C) heat preservation reaction for 12 hours, add deionized water to dilute, and obt...

Embodiment 3

[0020] Example 3: The slow-release concrete water-retaining agent of the present invention is made from the following components and parts by weight of raw materials: 31 parts of acrylamide monomers, 17.2 parts of hydroxypropyl acrylate as slow-release monomers parts, the initiator is 0.21 parts of azobisisobutylamidine hydrochloride, and 3300 parts of deionized water. The acrylamide monomer is a combination of 30 parts of acrylamide and 1 part of 2-acrylamide-2-methylpropanesulfonic acid. The preparation method of the slow-release concrete water-retaining agent comprises the following process steps: ① Dissolve the acrylamide monomer and the slow-release monomer in 200 parts of deionized water according to the above-mentioned parts by mass, and pour the solution into a three-necked flask In the process, start stirring, heat up to 60°C, then add an initiator in a three-necked flask, (at 60°C) heat preservation reaction for 11 hours, add deionized water to dilute, and obtain a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com