All-steel truck tread rubber material and preparation method thereof

A technology for trucks and tread rubber, applied in special tires, vehicle parts, tire parts, etc., can solve the problems of high rubber viscosity and strength requirements, difficulty in realizing all-steel tires, and large load on all-steel tires. Improved wet grip and cut resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

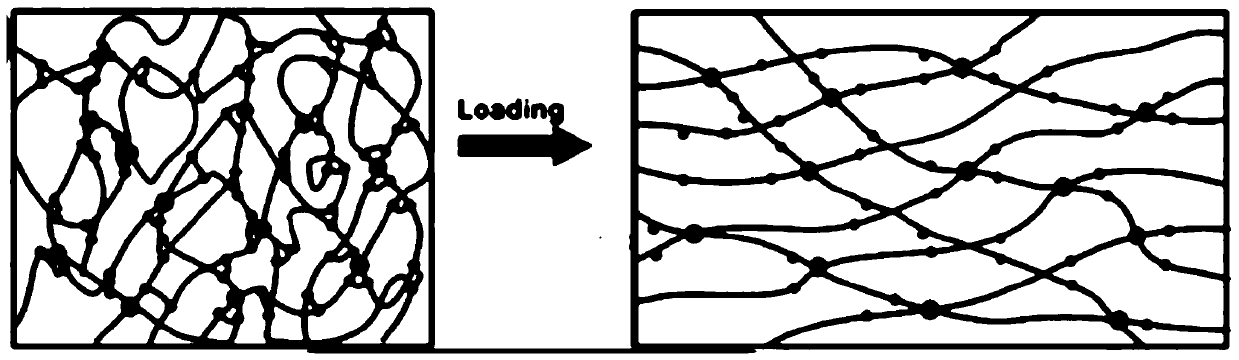

Method used

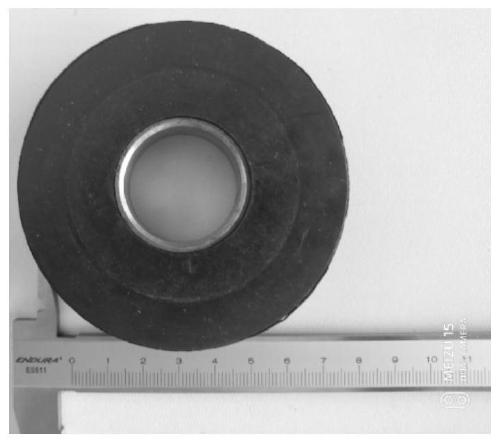

Image

Examples

Embodiment 1

[0021] An all-steel truck tread compound, said compound comprising 70 parts by weight of natural rubber, 30 parts of epoxidized natural rubber ENR, 1-6 parts of zinc acrylate ZDA, 45 parts of carbon black N1154, zinc oxide 4 parts, 1.5 parts of stearic acid, 2.8 parts of antioxidant 6PPD, 3 parts of microcrystalline wax, 1.7 parts of oil-extended sulfur, 0.9 parts of accelerator NS, 1.2 parts of accelerator DPG, and 0.18 parts of anti-scorch agent CTP.

[0022] The preparation method of the above-mentioned all-steel truck tread compound is carried out according to the following steps:

[0023] (a) Proportionally mix 1 / 3 of the total amount of epoxidized natural rubber ENR with zinc acrylate ZDA in an open mill and pre-disperse for 2 minutes; then put natural rubber and all epoxidized natural rubber ENR into Carry out mastication in the internal mixer for 20-40s, the mixing temperature is 40°C, the speed is 55-30rpm, first fast and then slow, and the pressure of the top bolt is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com