Composite heavy metal passivator and acidic heavy metal contaminated soil treatment method

A heavy metal passivation agent and composite technology, applied in chemical instruments and methods, restoration of polluted soil, land preparation methods, etc., can solve the problems of poor passivation stability, damage to soil ecology, loss of fertility, etc. The effect of improving soil acidity and increasing pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

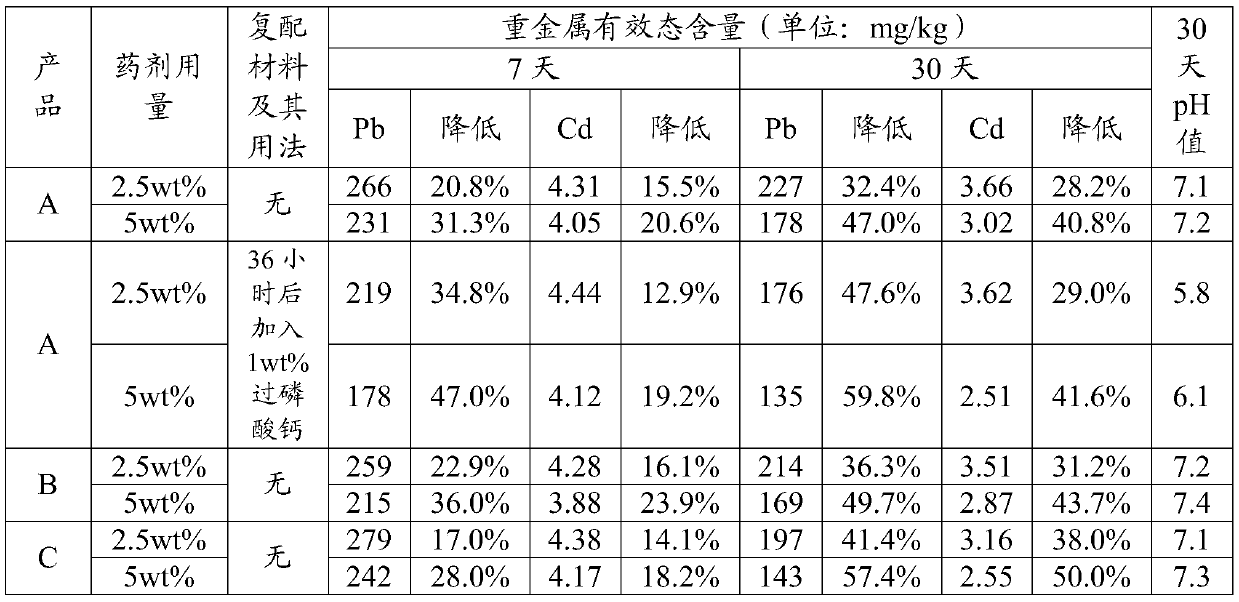

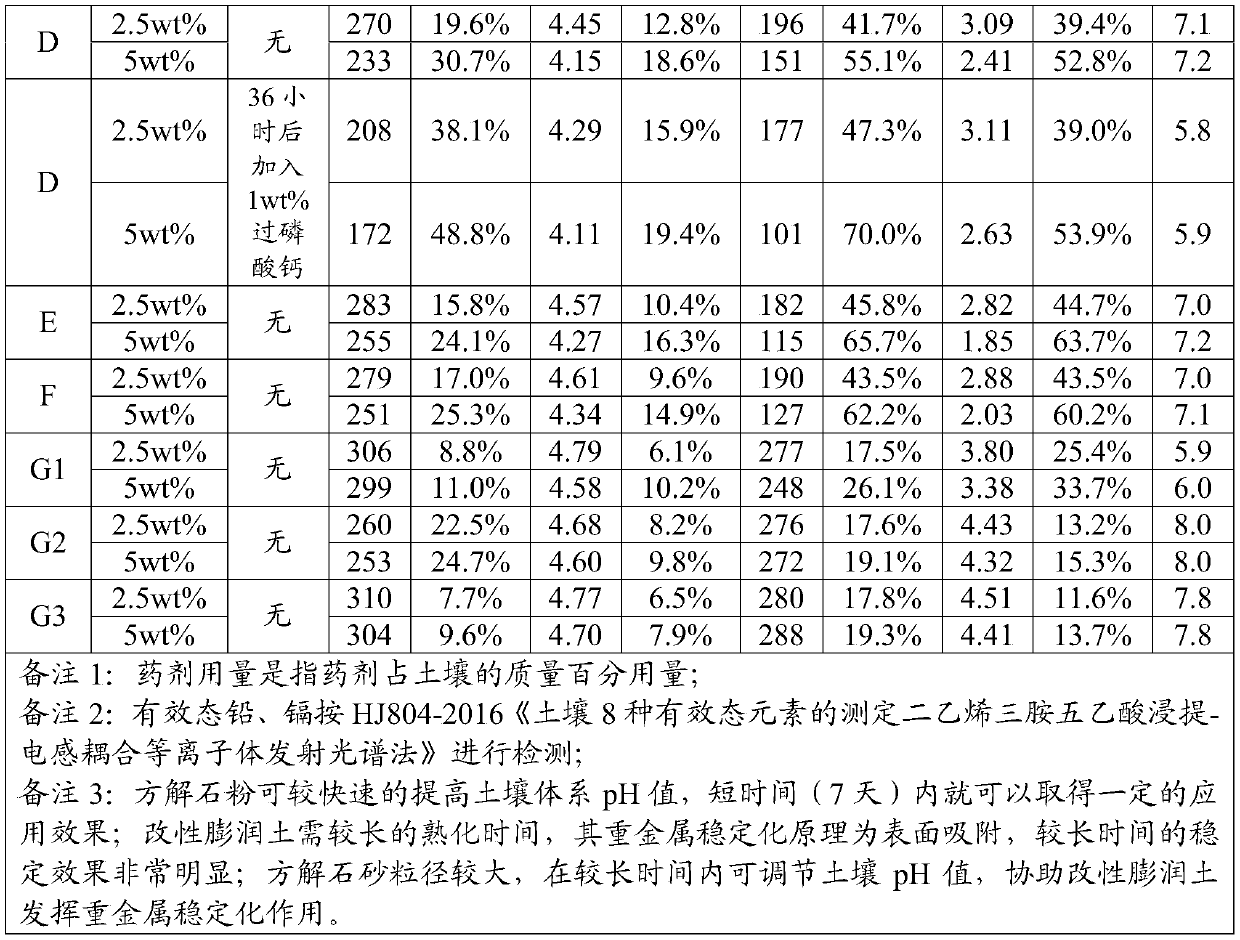

Examples

preparation example Construction

[0029] In the step of preparing the modified sodium bentonite provided by the present invention, the sodium bentonite is first burned to realize the activation of the sodium bentonite. Wherein, the cation exchange capacity (CEC) of the sodium-based bentonite is preferably ≥ 800mmol / kg; the proportion of particle size ≤ 200 mesh in the sodium-based bentonite is preferably ≥ 95wt%; the burning temperature is preferably 300-450°C, Specifically, it can be 300°C, 305°C, 310°C, 315°C, 320°C, 325°C, 330°C, 335°C, 340°C, 345°C, 350°C, 355°C, 360°C, 365°C, 370°C, 375°C , 380°C, 385°C, 390°C, 395°C, 400°C, 405°C, 410°C, 415°C, 420°C, 425°C, 430°C, 435°C, 440°C, 445°C or 450°C; The time is preferably 3~5h, specifically 3h, 3.1h, 3.2h, 3.3h, 3.4h, 3.5h, 3.6h, 3.7h, 3.8h, 3.9h, 4h, 4.1h, 4.2h, 4.3h , 4.4h, 4.5h, 4.6h, 4.7h, 4.8h, 4.9h or 5h. After burning, heat-activated sodium bentonite is obtained.

[0030] In the step of preparing the modified sodium-based bentonite provided by the p...

Embodiment 1

[0052] 1) Put the sodium-based bentonite in a muffle furnace and burn it at 300°C for 3 hours, then cool it down to 150°C naturally in the furnace, take it out and put it in a desiccator to cool down for later use.

[0053] 2) Add 250g of deionized water into a 500ml three-port reactor, start stirring, add 60g of sodium bentonite after burning treatment, and raise the temperature inside the reactor at a heating rate of 6-8°C / min to 50°C, dropwise add 10wt% hydrochloric acid aqueous solution thereinto, adjust the pH value of the solution to 3.0, keep the reaction for 2 hours, filter, wash until the filtrate is neutral, and dry.

[0054] 3) Add 250 g of deionized water into the reactor, start stirring, and add the dry bentonite from the reaction product of the previous step. While stirring, raise the temperature inside the reactor to 70°C at a rate of 6-8°C / min. After the temperature is stable, add 5.2g of octadecyltrimethylammonium chloride to it, keep it warm for 3 hours, and ...

Embodiment 2

[0057] 1) Put the sodium bentonite in a muffle furnace and burn it at 300°C for 5 hours, then cool it down to 150°C naturally in the furnace, take it out and put it in a desiccator to cool down for later use.

[0058] 2) Add 250g of deionized water into a 500ml three-port reactor, start stirring, add 60g of sodium bentonite after burning treatment, and raise the temperature inside the reactor at a heating rate of 6-8°C / min to 70°C, dropwise add 10wt% hydrochloric acid aqueous solution thereinto, adjust the pH value of the solution to 3.5, keep the reaction for 3 hours, filter, wash until the filtrate is neutral, and dry.

[0059] 3) Add 250 g of deionized water into the reactor, start stirring, and add the dry bentonite from the reaction product of the previous step. While stirring, raise the temperature inside the reactor to 90°C at a rate of 6-8°C / min. After the temperature stabilizes, add 5.2g of octadecyltrimethylammonium chloride to it, keep it warm for 5 hours, and filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com