Drilling and tunneling type full-sleeve combination

A technology of full casing and casing, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as large deviation of protective layer thickness, easy collapse of holes, and easy deviation of rear-inserted steel cages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the embodiments described in the accompanying drawings.

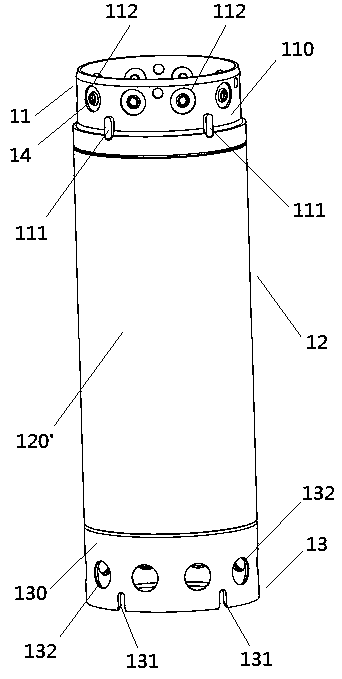

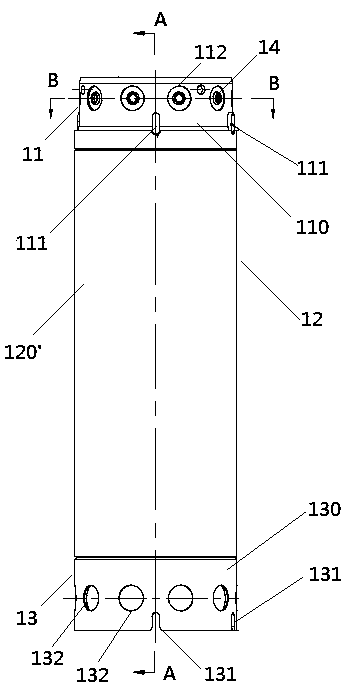

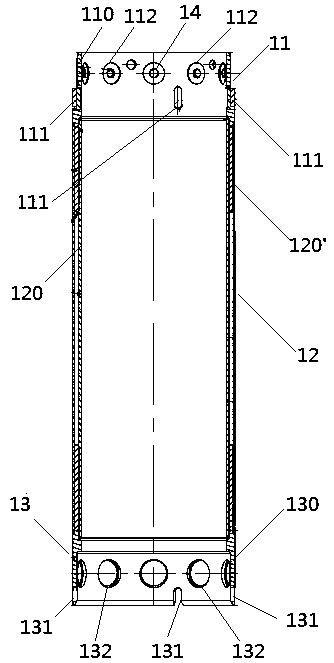

[0043] Such as Figure 1-13 As shown, a drilling-type complete casing combination is composed of multiple unit casings and bottom casings. Each unit casing includes a casing body 12, an outer joint 11, an inner joint 13, a locking disc 14, and a locking cover 15. Bottom casing included. Bottom pipe body 16, outer joint 11, locking disc 14, locking cover 15, tool rest seat 17 and a plurality of cutting tool bodies 18, casing body 12 comprises inner tubular body 120 and outer tubular body 120'; outer joint 11 comprises outer Joint ring 110, positioning block 111 positioned at the lower end of the outer wall of the outer joint ring and a plurality of outer head counterbores 112 arranged on the outer joint ring; the inner joint 13 includes an inner joint ring 130, a positioning groove 131 positioned at the lower end of the outer wall of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com