Fireproof cable and production process thereof

A fire-resistant cable and production process technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve problems such as limited fire resistance, fire, and affecting use safety, so as to save labor costs, reduce production costs, and stabilize fire performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

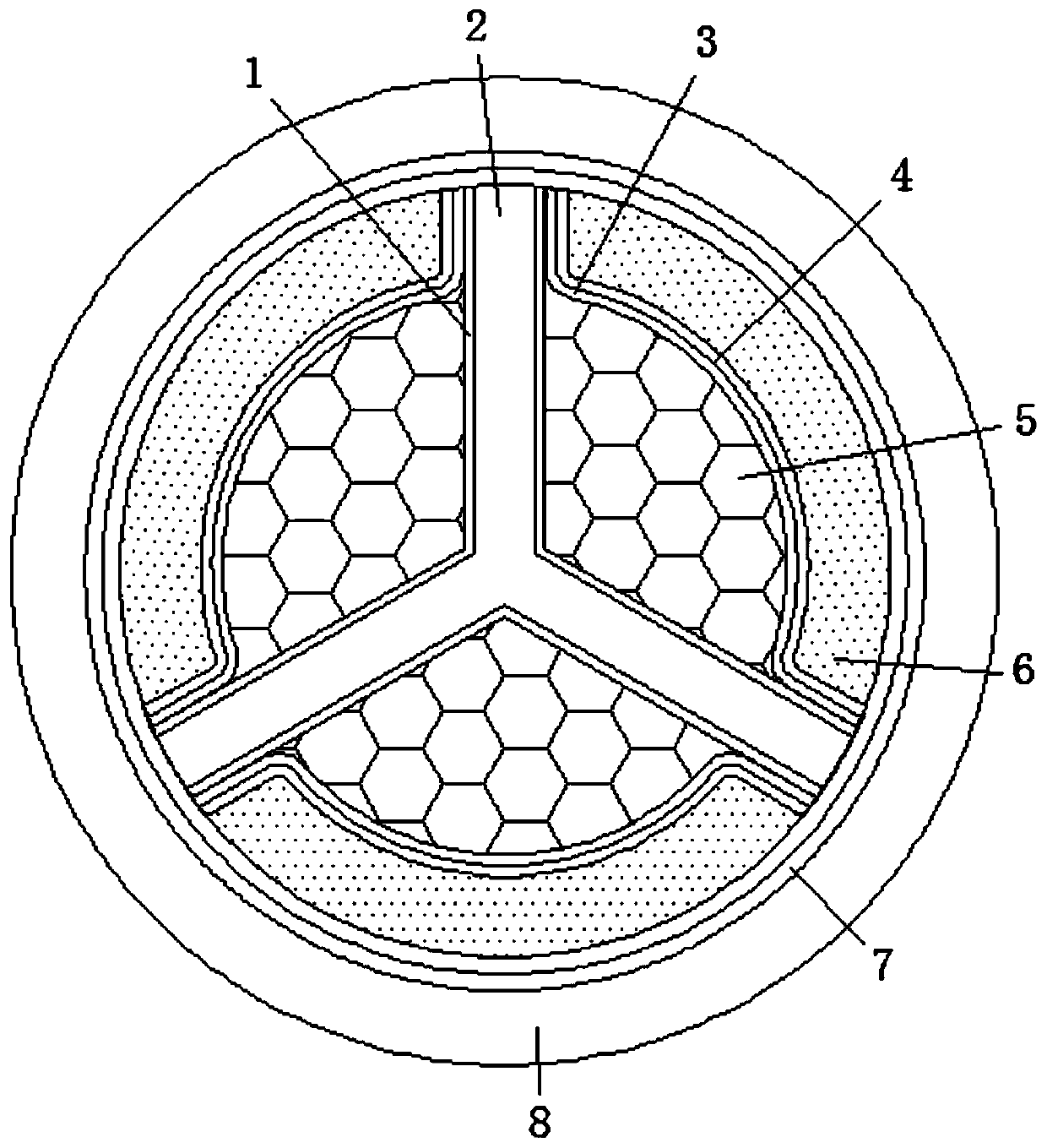

[0033] see figure 1 As shown, it is a structural schematic diagram of a fireproof cable provided in this embodiment, which specifically includes: from inside to outside, it includes a fireproof skeleton 2, an insulating and heat insulating layer 1, a conductive core 5, a shielding layer 3, an insulating coating 4, Refractory filling layer 6, mica tape layer 7 and protective cover 8; wherein:

[0034] The refractory skeleton 2 is provided with at least three clamping grooves in an annular array; the insulating and heat insulating layer 1 is coated on the inner wall of the clamping groove; the conductive core 5 is filled in the clamping groove, and there are multiple conductive cores in each clamping groove 5. The shielding layer 3 is covered on the outside of the conductive core 5 and bonded to the refractory frame 2; the insulating coating 4 is bonded to the outside of the shielding layer 3, and the refractory filling layer 6 is filled in the clamping groove and matched with t...

Embodiment 2

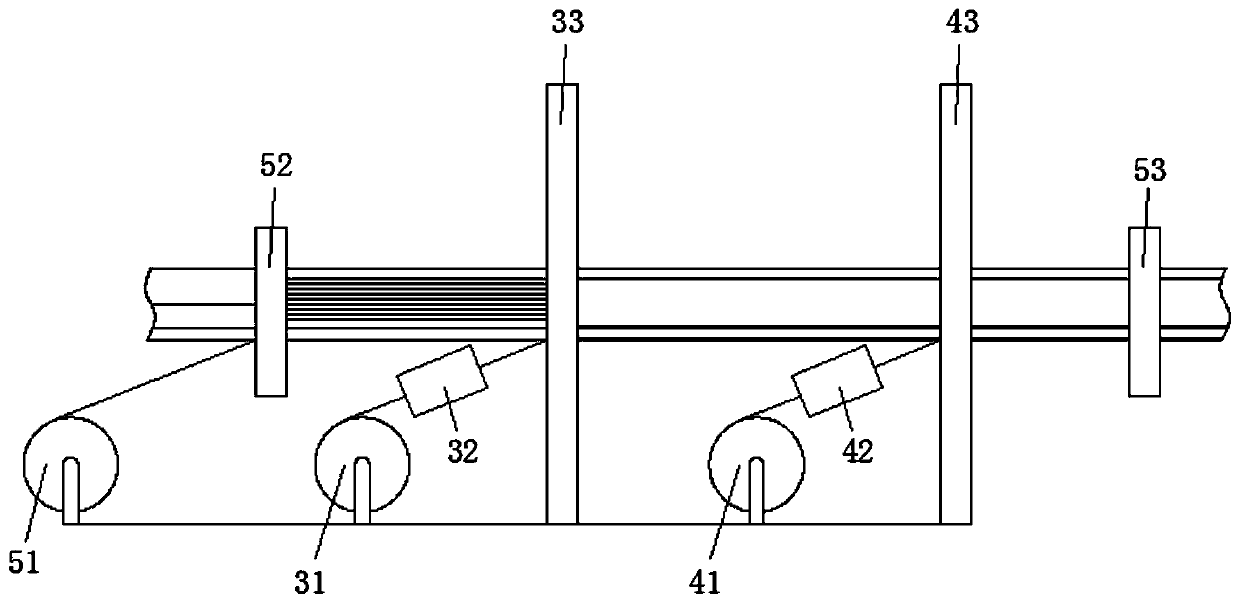

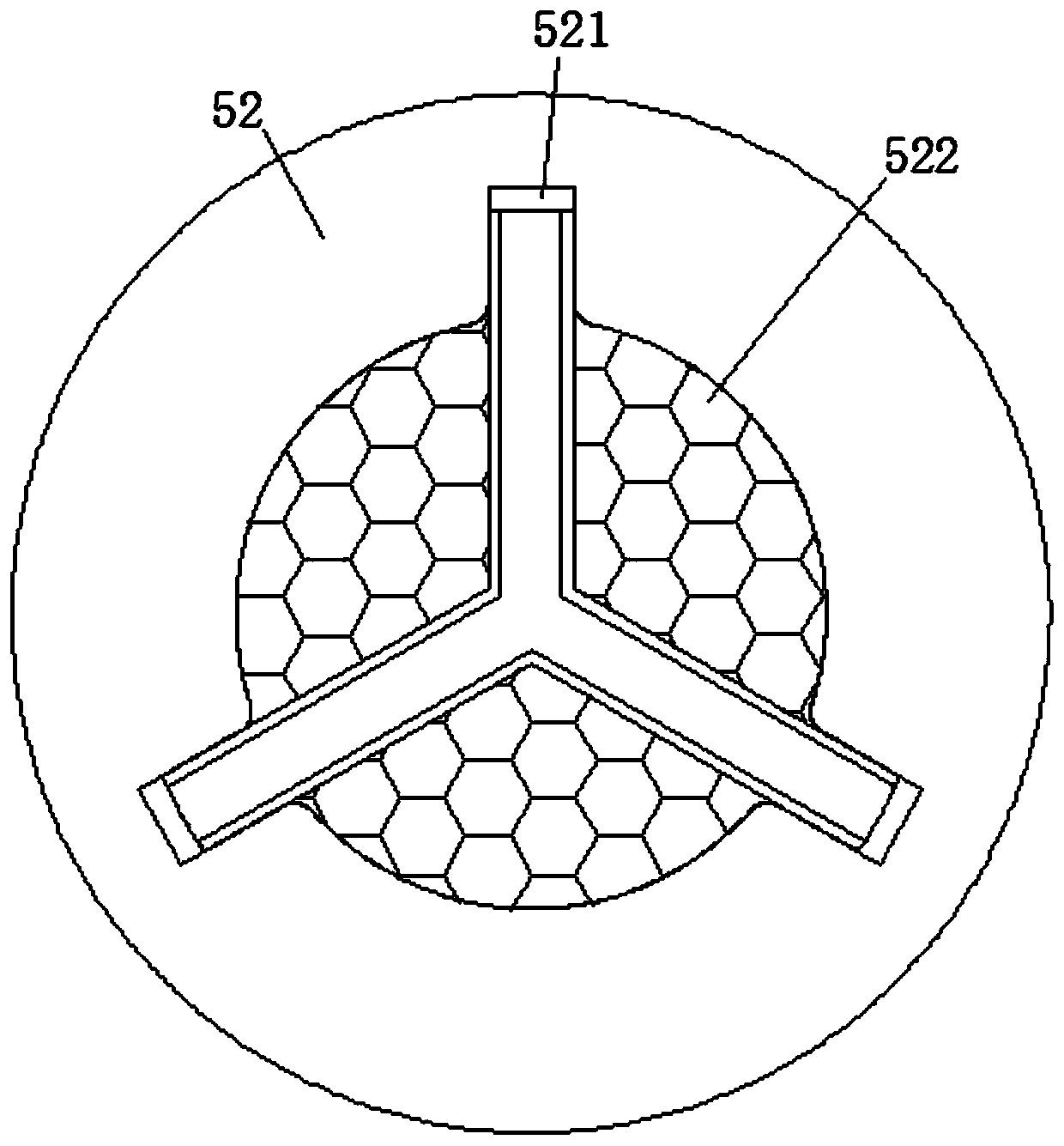

[0040] see Figure 2-7 As shown, it is a structural diagram of equipment used in the production process of a fireproof cable provided in this embodiment, and the final produced fireproof cable is the fireproof cable disclosed in the embodiment, which specifically includes the following production steps:

[0041] S1. Wire-drawing forming of the conductive core 5 (not shown in the figure): wire-drawing the metal blank with a forming die to form the conductive core 5 with a diameter meeting the requirement.

[0042] S2. Composite molding of the conductive core 5 and the refractory skeleton 2: the refractory skeleton 2 is formed based on an extruder (not shown in the figure), and a plurality of conductive cores 5 and the refractory skeleton 2 are introduced into the wire production system to obtain a composite type wire.

[0043]Wherein: the wire production system is provided with a feeding mechanism, an assembling mechanism and a discharging mechanism sequentially along the forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com