Feed supply system for pig farm

A supply system and pig farm technology, applied in the field of animal breeding equipment, can solve the problems affecting the quality of pork, the small amount of breeding, and the adverse effects on pig health, so as to eliminate potential safety hazards, improve precise control, and improve pork quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

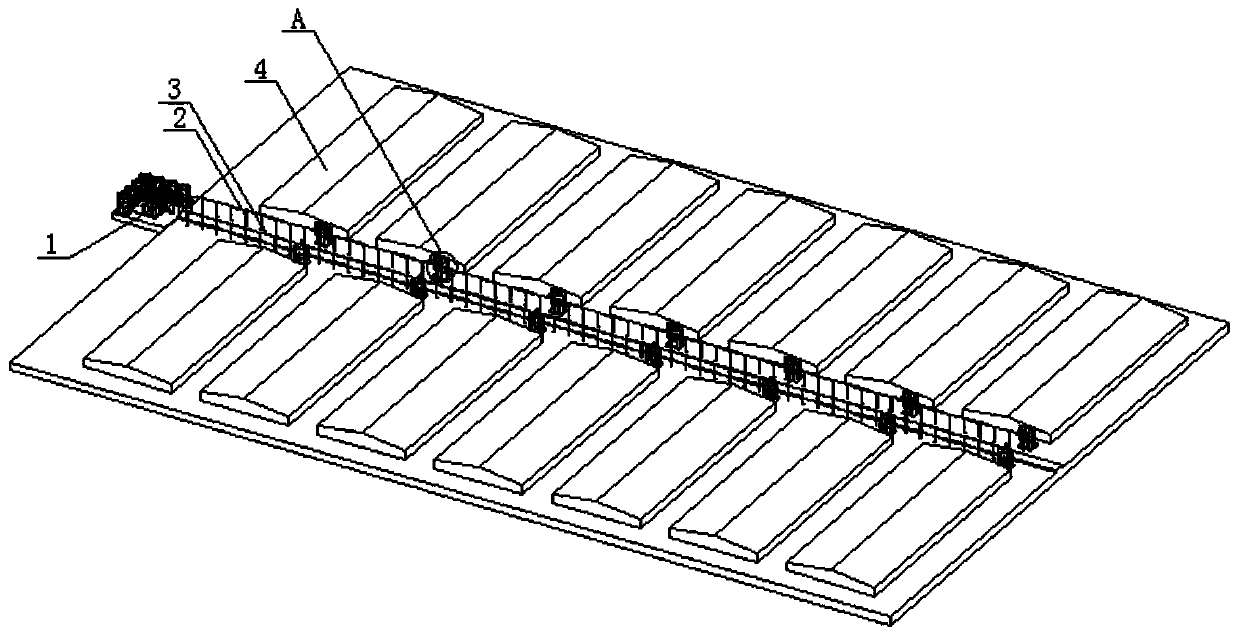

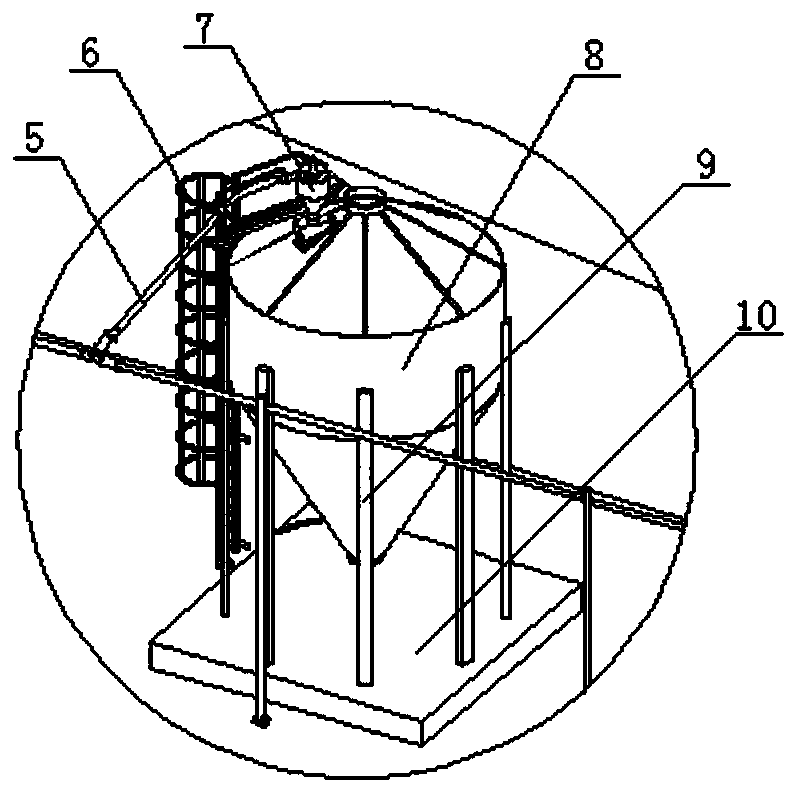

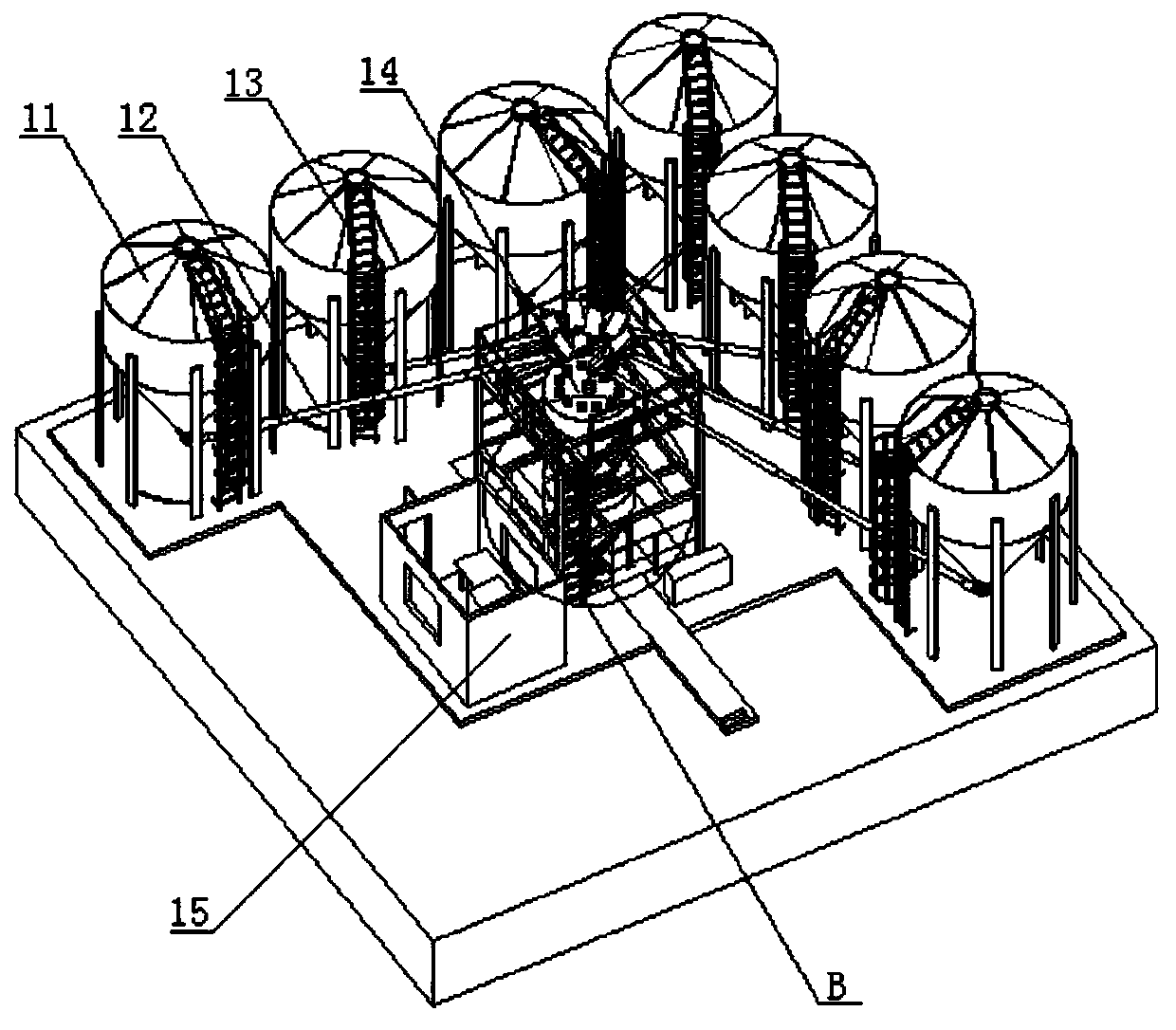

[0022] In order to make the description more clear, in combination with the accompanying drawings of the description Figure 1 to Figure 4 , a feed supply system for pig farms of the present invention is further described.

[0023] A feed supply system for pig farms, comprising a batching part 1, the batching part 1 includes a feed bin 11 and a control room 15, and is characterized in that: an auger 12 is arranged at the bottom of the feed bin 11, and one end of the auger 12 is is the feed end, and the end of the auger 12 far from the feed end is the discharge end, the feed end of the auger 12 is fixedly connected with the bottom of the silo 11, the auger 12 extends obliquely upward, and the The batching scale 14 is arranged below the discharge end of the auger 12, and the batching scale 14 is provided with a warehouse 18 to be delivered, and a booster pump 16 is arranged on the side below the warehouse 18 to be delivered. One side of the booster pump 16 is provided with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com