Control method of electric toothbrush

An electric toothbrush and control method technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems that consumers cannot adapt, the elderly and children find it difficult to use electric toothbrushes, and cannot realize manual toothbrush ready-to-use, etc. Achieve the effect of improving user experience and protecting dental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

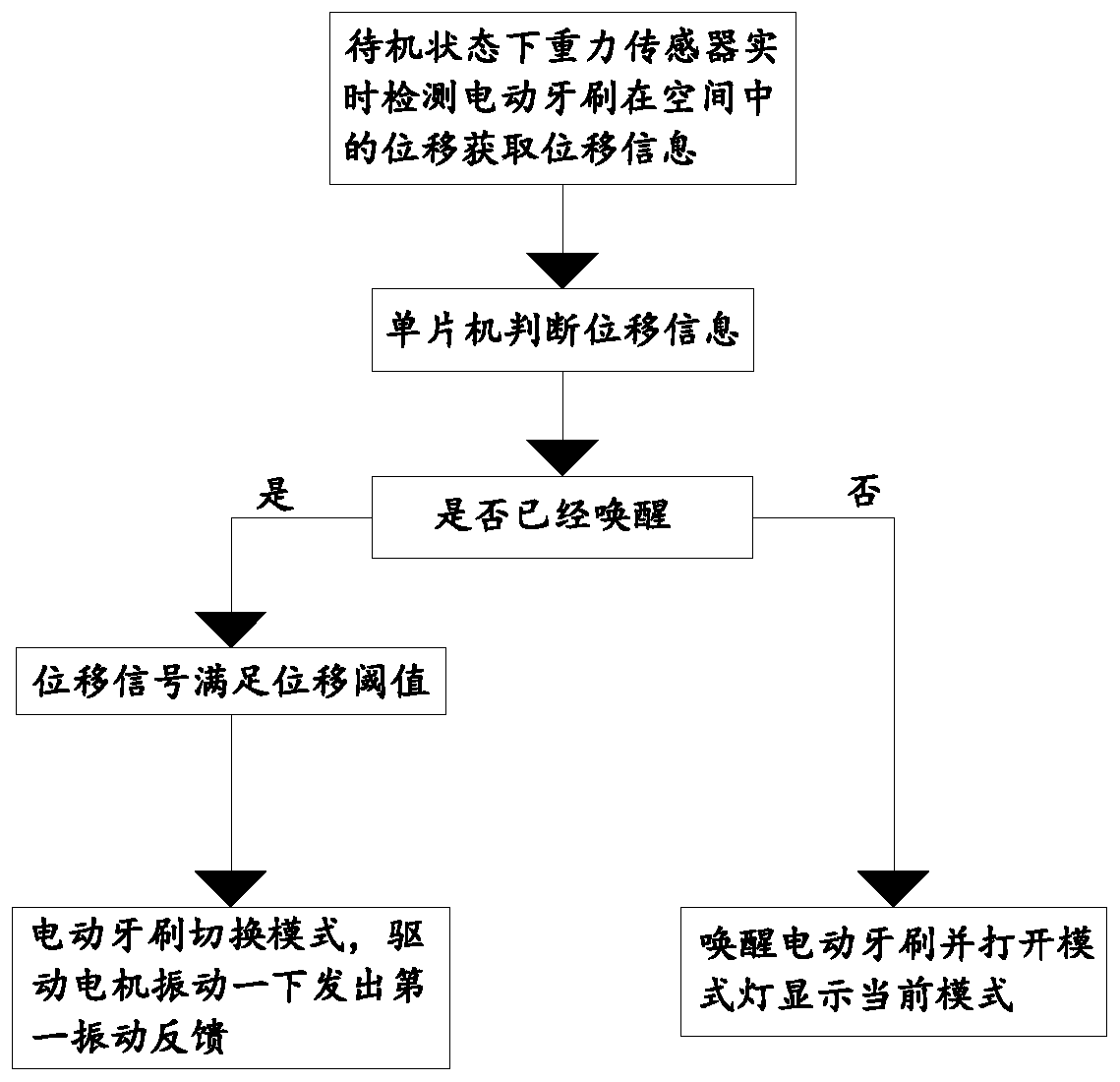

[0070] Embodiment one: if figure 2 As shown, when the electric toothbrush is in the standby state, the gravity sensor 3 of the present invention detects and acquires the displacement signal in real time, and sends it to the single-chip microcomputer 2, and the single-chip microcomputer 2 controls the electric toothbrush to enter the wake-up state, and turns on the mode light to display the position of the electric toothbrush. Current mode; after entering the wake-up state, the gravity sensor 3 continues to detect the displacement information of the electric toothbrush in real time and sends a displacement signal to the single-chip microcomputer 2. When the displacement signal received by the single-chip microcomputer 2 satisfies the set displacement threshold, the single-chip microcomputer 2. Control the electric toothbrush to switch modes, and control the drive motor 5 to send the first vibration feedback, and turn on the mode light to display the current mode.

Embodiment 2

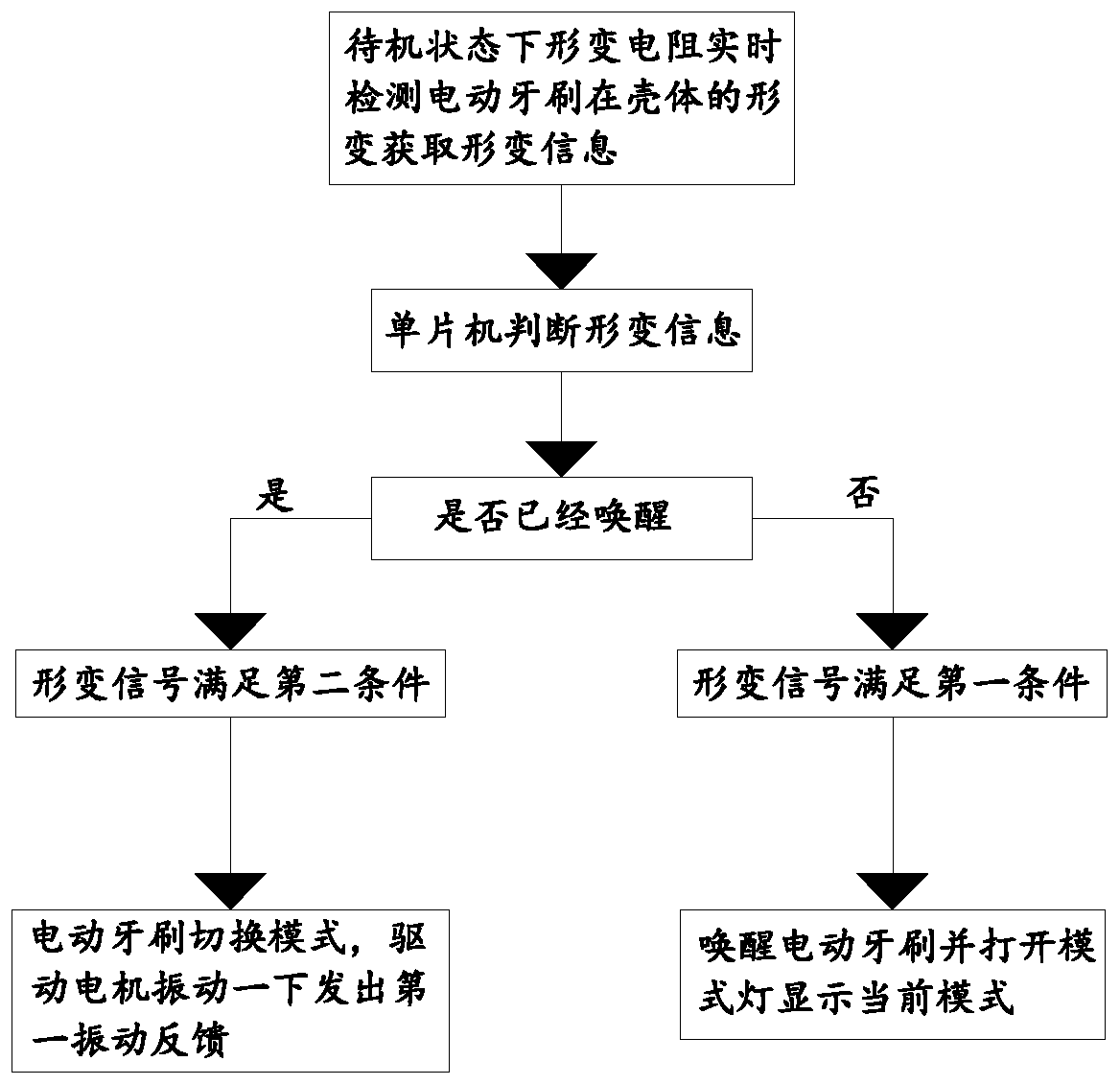

[0071] Embodiment two: if image 3 As shown, the deformation resistor 9 of the present invention detects and acquires the deformation signal in real time when the electric toothbrush is in a standby state, and sends it to the single-chip microcomputer 2. When the deformation signal received by the single-chip microcomputer 2 satisfies the first condition set, the The single-chip microcomputer 2 controls the electric toothbrush to enter the wake-up state, and turns on the mode light to display the current mode; after entering the wake-up state, the deformation resistor 9 detects the deformation information on the electric toothbrush housing in real time and converts it into a deformation signal and sends it to the single-chip microcomputer 2. 2. When it is judged that the deformation signal satisfies the set second condition, control the electric toothbrush to switch modes, and control the drive motor 5 to send the first vibration feedback, and turn on the mode light to display ...

Embodiment 3

[0074] Embodiment 3: The gravity sensor 3 of the present invention detects and obtains the displacement signal in real time when the electric toothbrush is in the standby state, and sends it to the single-chip microcomputer 2. When the single-chip microcomputer 2 receives the displacement signal and meets the displacement threshold, it controls the electric toothbrush Enter the wake-up state, and turn on the mode light to display the current mode of the electric toothbrush; after the electric toothbrush enters the wake-up state, the gravity sensor 3 detects the displacement information of the electric toothbrush immediately, and sends the displacement signal to the single-chip microcomputer 2, and the single-chip microcomputer 2 immediately Judging whether the displacement signal meets the set displacement threshold, if the displacement signal satisfies the displacement threshold, the single-chip microcomputer 2 controls the electric toothbrush to switch modes immediately after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com