Battery disposal facility

A battery processing and equipment technology, applied in the field of logistics sorting equipment, can solve problems such as battery pollution, affecting battery processing efficiency, and incapable of efficient battery cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

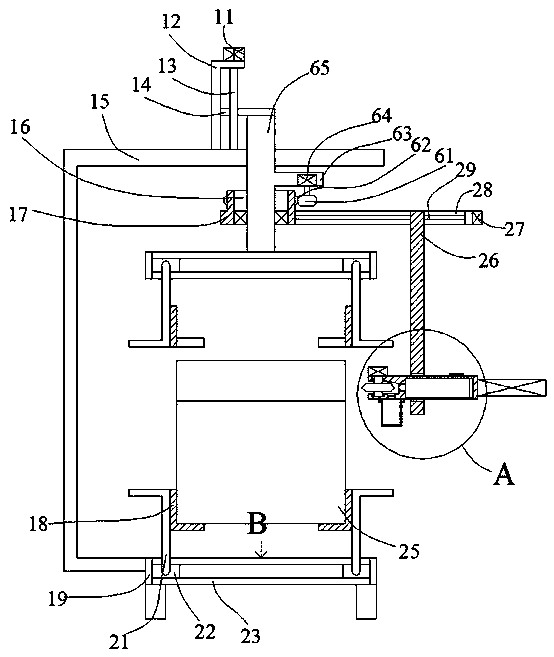

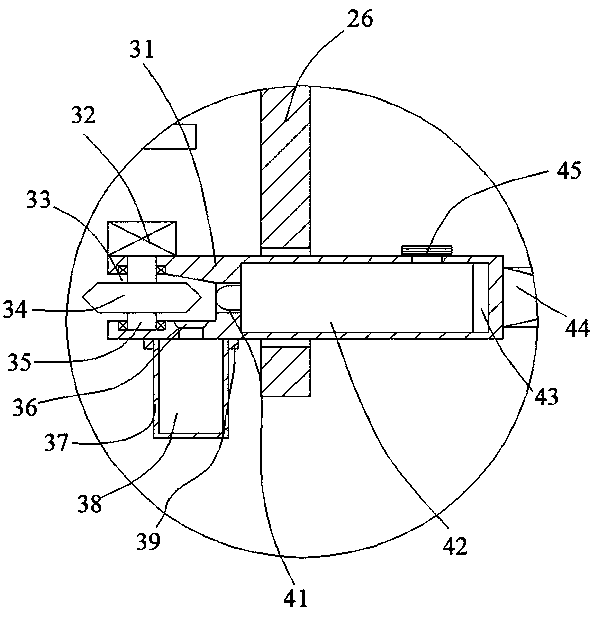

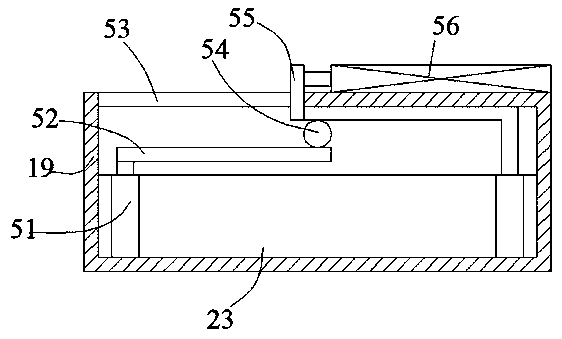

[0022] Such as Figure 1-Figure 3 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are consistent. A battery processing equipment of the present invention includes a support frame 15, a battery 25 to be cut is arranged on one side of the support frame 15, and a top support platform is fixed on the upper end of the support frame 15. 12. The upper end surface of the top supporting platform 12 is fixed with a top motor 11, and the lower side of the top motor 11 is connected with a motor matching rod 13, and the motor matching rod 13 is rotatably connected with the support frame 15. The outer surface of the motor matching rod 13 is screwed and connected with a lifting matching plate 14, and the lifting matching plate 14 is connected with the top support platform 12 by sliding fit. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com