A method for improving the production efficiency of copper or aluminum wire

A manufacturing efficiency, aluminum metal technology, applied in the field of improving the production efficiency of copper or aluminum metal wire, can solve the problems of affecting the back-twisting treatment, failure to clamp, and many torsion angles, so as to improve the production and manufacturing efficiency and improve the overall Efficiency, the effect of improving the clamping tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

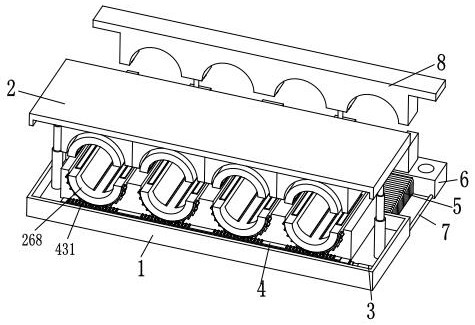

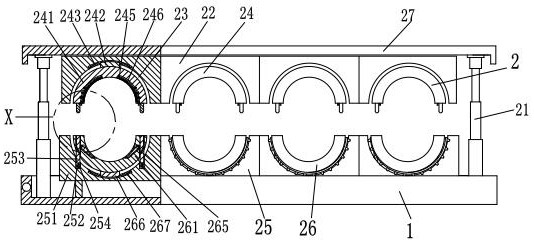

[0034] like Figure 1 to 6 As shown, a method of increasing the production of copper or aluminum wire is produced, which uses a retracting apparatus including a base 1, a retracting device 2, a driving cylinder 3, an adjustable rack 4, The telescopic tube 5, the stationary seat 6, the slider 7, and the clamping device 8 are used to improve the manufacturing efficiency of the copper or aluminum wire to increase the copper or aluminum wire, as follows:

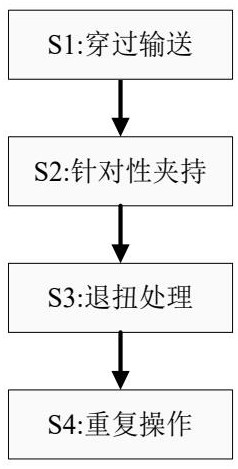

[0035] S1, passing through the delivery: The free end of the copper or aluminum wire is sequentially pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com