Automatic liquid changing device for computer numerical control machine tool

A CNC machine tool, automatic technology, applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of increasing the labor intensity of CNC machine tool personnel, affecting the normal use of CNC machine tools, and leakage of coolant, etc., to achieve structural Simple and reasonable, strong practicability, and the effect of avoiding vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

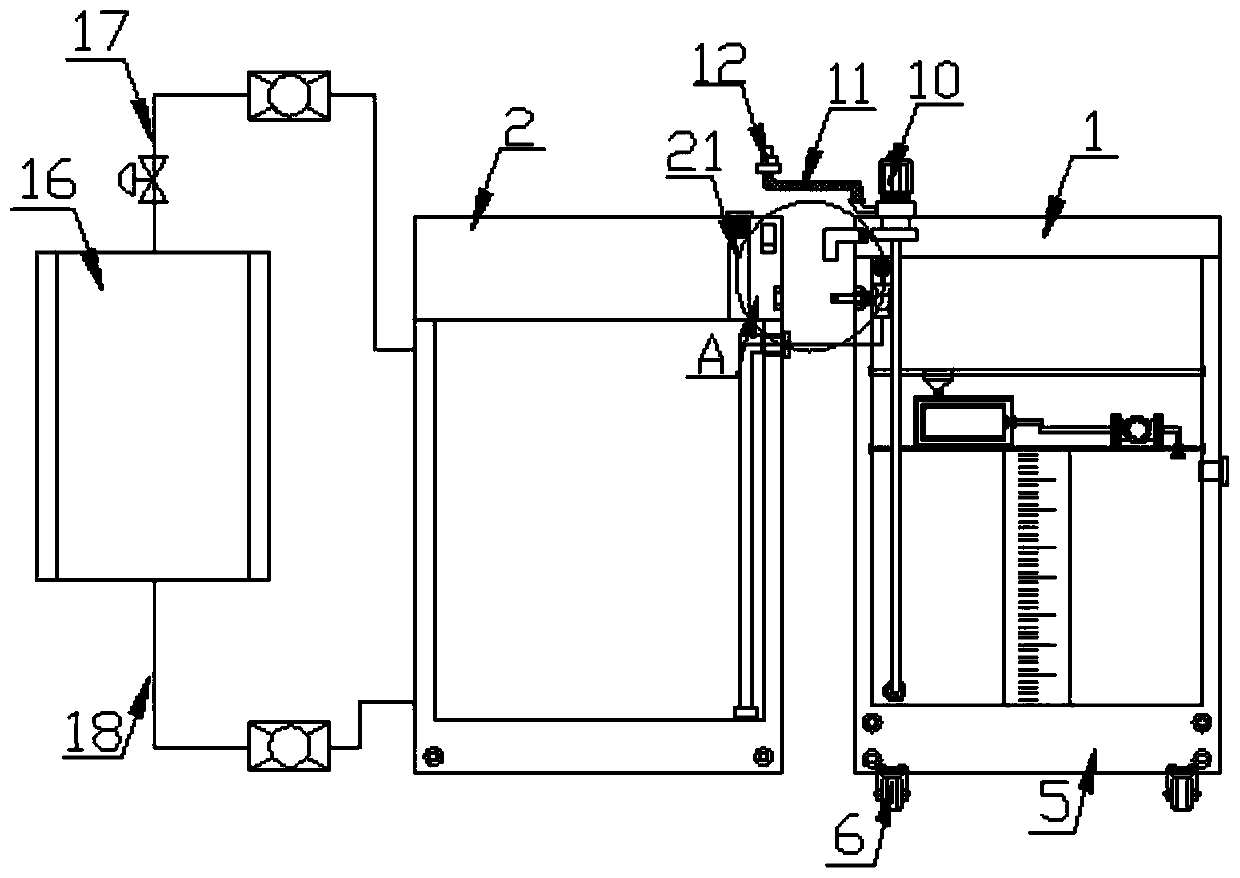

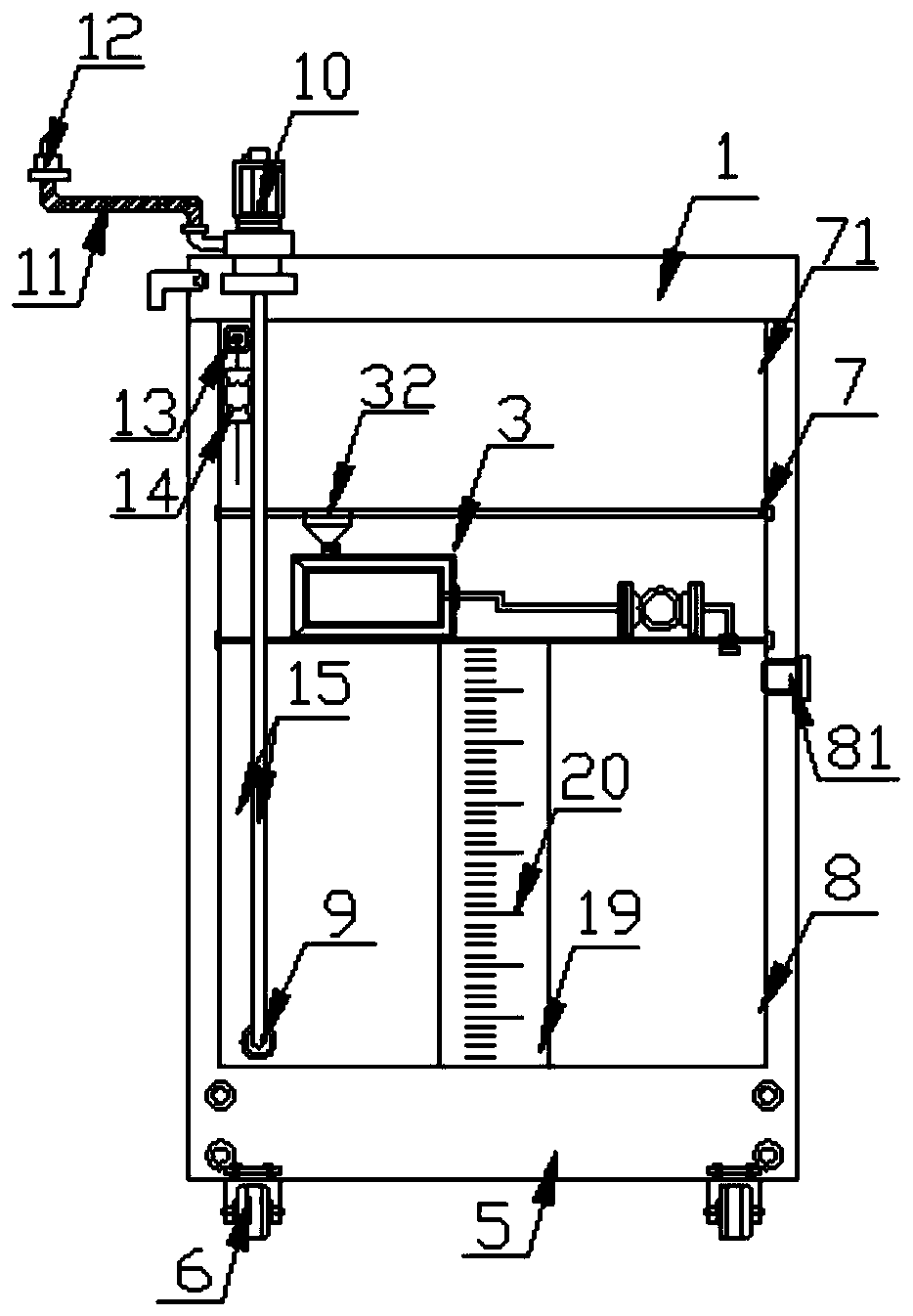

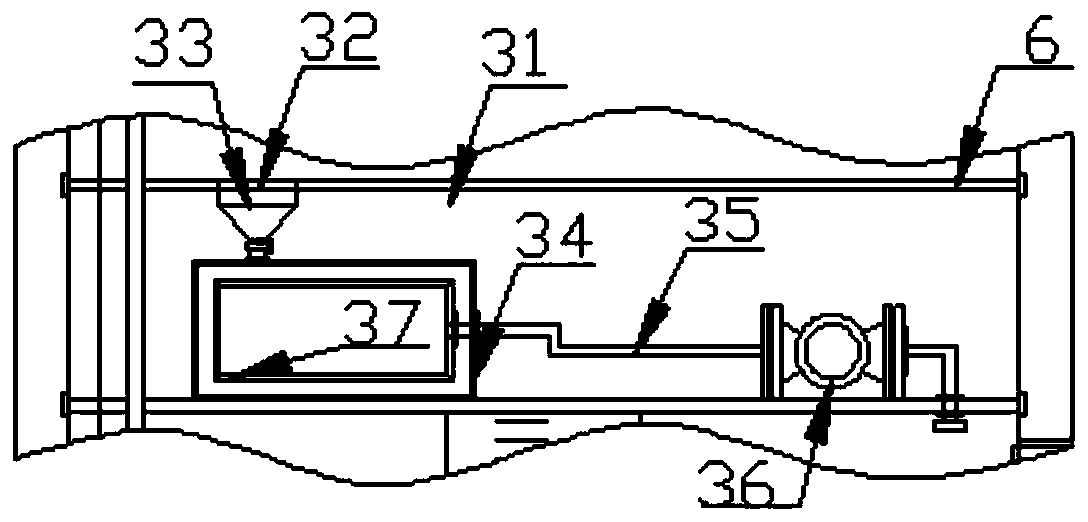

[0022] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: an automatic liquid exchange device for numerical control machine tools, including a liquid exchange box 1, a circulation mechanism 3 and an installation protection mechanism 4, and the bottom of the liquid exchange box 1 is fixedly installed with Base 5, four moving wheels 6 are fixedly installed on the bottom of the base 5, and a protective mechanism 4 is installed on one side of the liquid exchange box 1, and the liquid exchange box 1 is connected with the machine tool box by the protective mechanism 4 The body 2 is detachably and fixedly installed, and the machine tool box 2 is fixedly installed on the bottom of the CNC machine tool 16, and the top of one side of the machine tool box 2 communicates with the input end of the cooling system of the CNC machine tool 16 through the liquid inlet pipe 17, so that The output end of the cooling system of the numerical control mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com