Bamboo rapid triangle hole opening device for bamboo chair processing

A technology of bamboo chairs and triangular holes, which is applied in the field of rapid triangular hole opening devices in bamboo, which can solve the problems of poor opening position accuracy, dependence on line drawing accuracy, and low production efficiency, so as to achieve guaranteed cutting effect, good cutting effect, and good positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

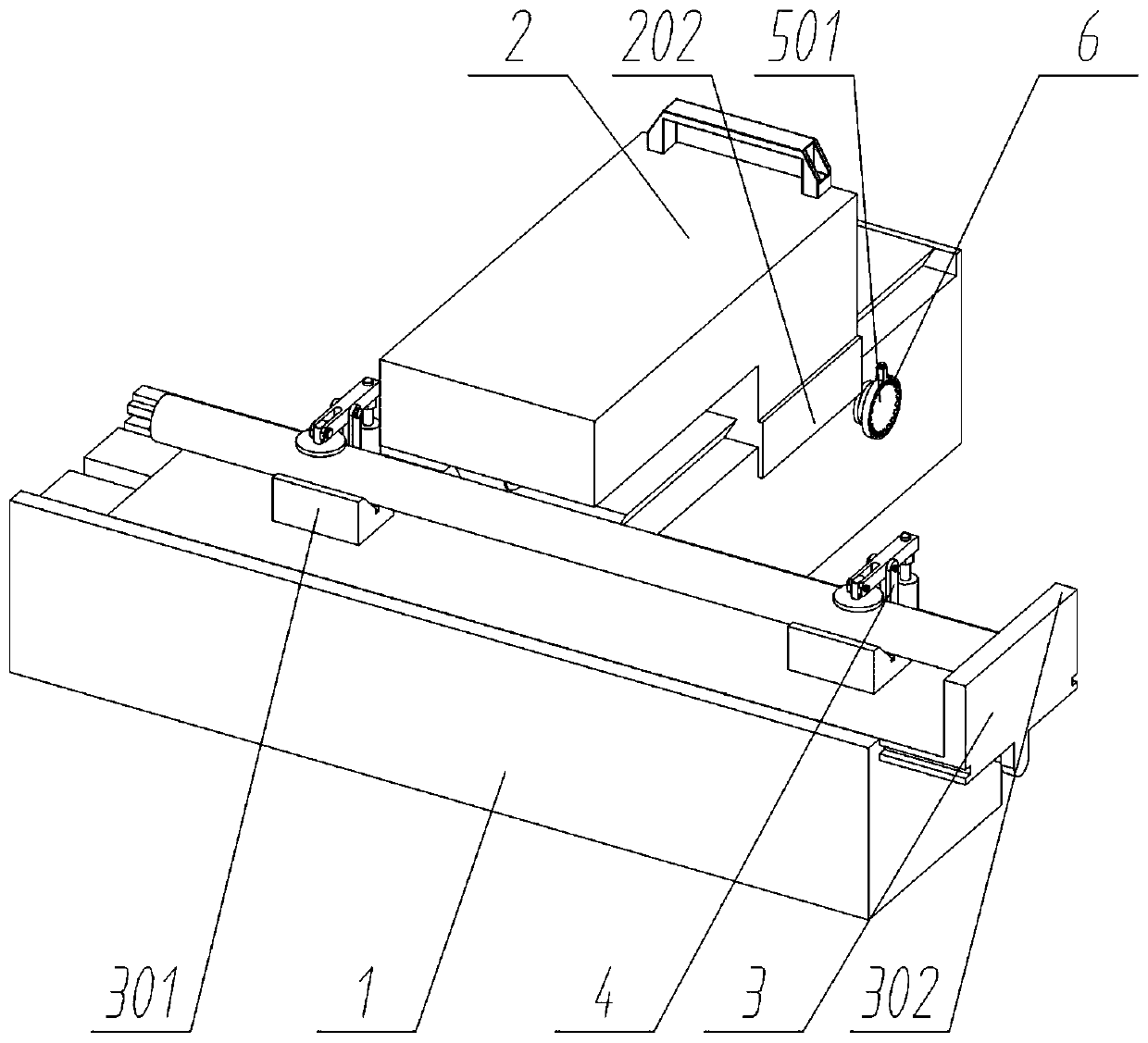

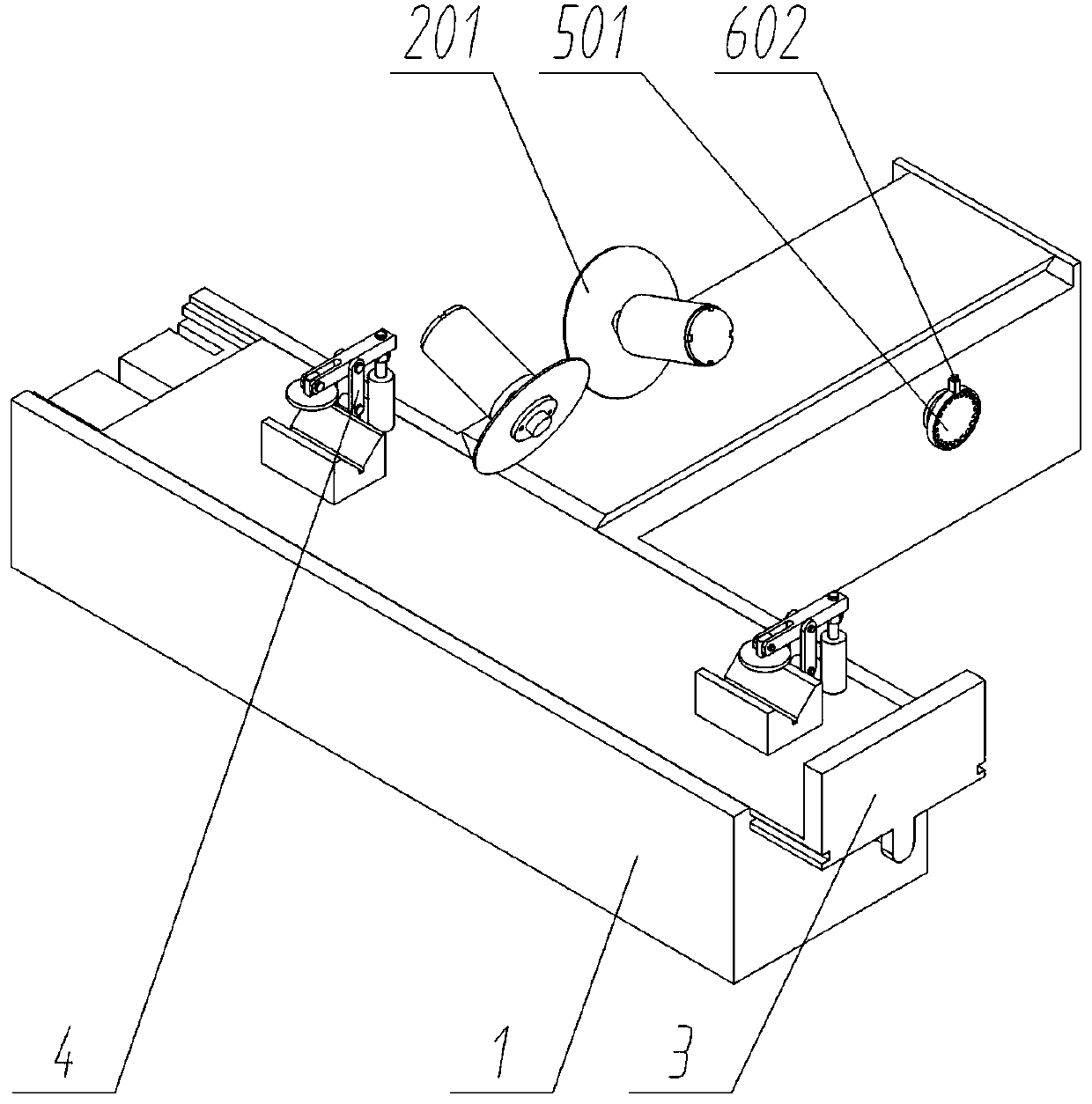

[0031] see Figure 1 to Figure 8 , a kind of embodiment that the present invention provides: a kind of bamboo triangular hole opening device that is used for bamboo chair processing quickly, comprises frame 1; The top rear of frame 1 is slidingly connected with a group of cutting device 2; There is a group of sliding workbench 3 slidingly connected at the top; a group of pressing devices 4 are arranged on the left and right sides of the upper end surface of the sliding workbench 3; A group of driving balance wheels 6 is axially connected on the right side; a group of driven pulleys 7 is axially connected on the inner side of the front part of the frame 1 .

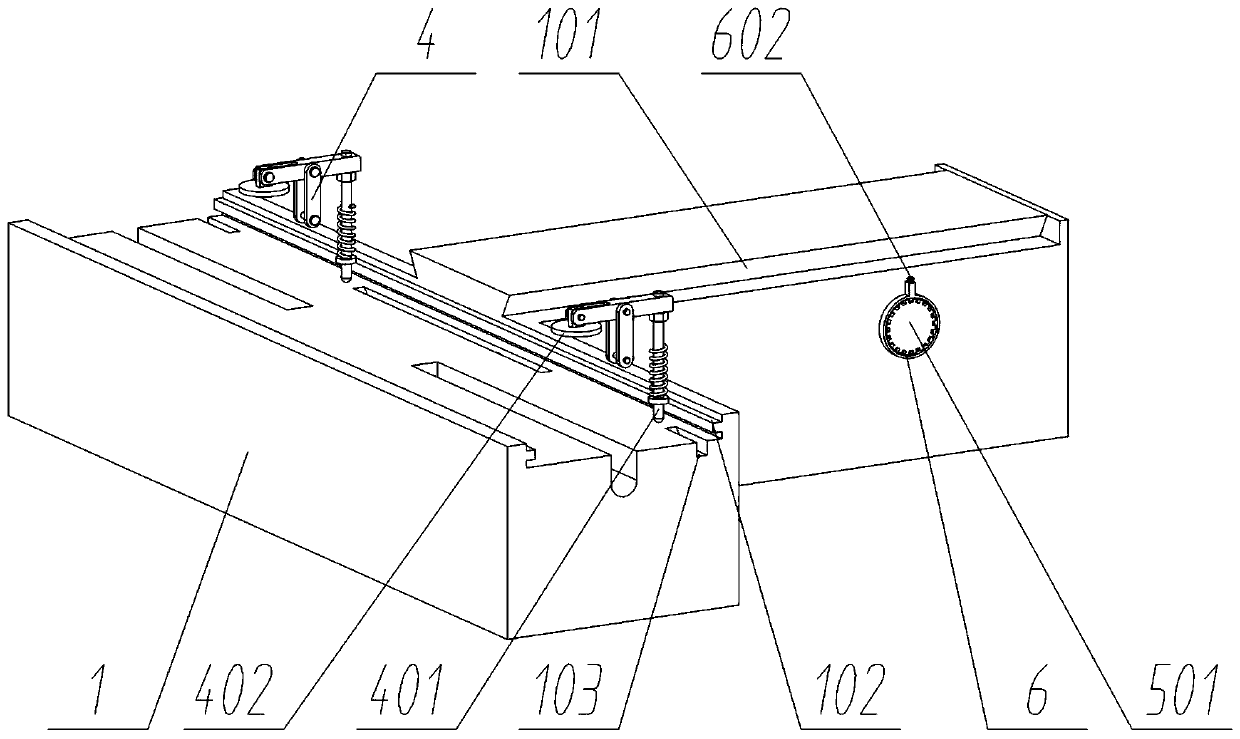

[0032] Further, the frame 1 also includes a cutting slide guide block 101, a group of cutting slide guide blocks 101 are arranged above the rear of the frame 1, the cutting slide guide blocks 101 are dovetail-shaped structures, and the cutting device 2 passes through the cutting slide guide blocks 101 and The frame 1 is s...

Embodiment 2

[0038] On the basis of Example 1, please refer to figure 1 , image 3 and Figure 4 , an embodiment provided by the present invention: a device for quickly opening triangular holes in bamboo used for processing bamboo chairs. Eighty-degree ratchet 602, the driving pulley 5 also includes an inner ratchet 501, and the left end face of the driving pulley 5 is coaxially fixedly connected with a group of inner ratchets 501, and the inner ratchet 501 and the ratchet 602 together form a gear that can change the transmission direction. The reversible ratchet mechanism, in use, the driving balance wheel 6 drives the driving pulley 5 to perform unidirectional transmission through the reversible ratchet mechanism during the rotation process.

[0039] Further, the outside of the driving pulley 5 and the driven pulley 7 are connected by a synchronous belt transmission to form a synchronous belt transmission mechanism, and the driven pulley 7 is driven to rotate by the driving pulley 5 th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap