Wood board cutting device for furniture production machining

A technology for cutting devices and wood boards, which is applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve the problems of reducing board cutting efficiency, large cutting work errors, and reducing economic benefits, etc., to improve convenience, Guaranteed cutting effect and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

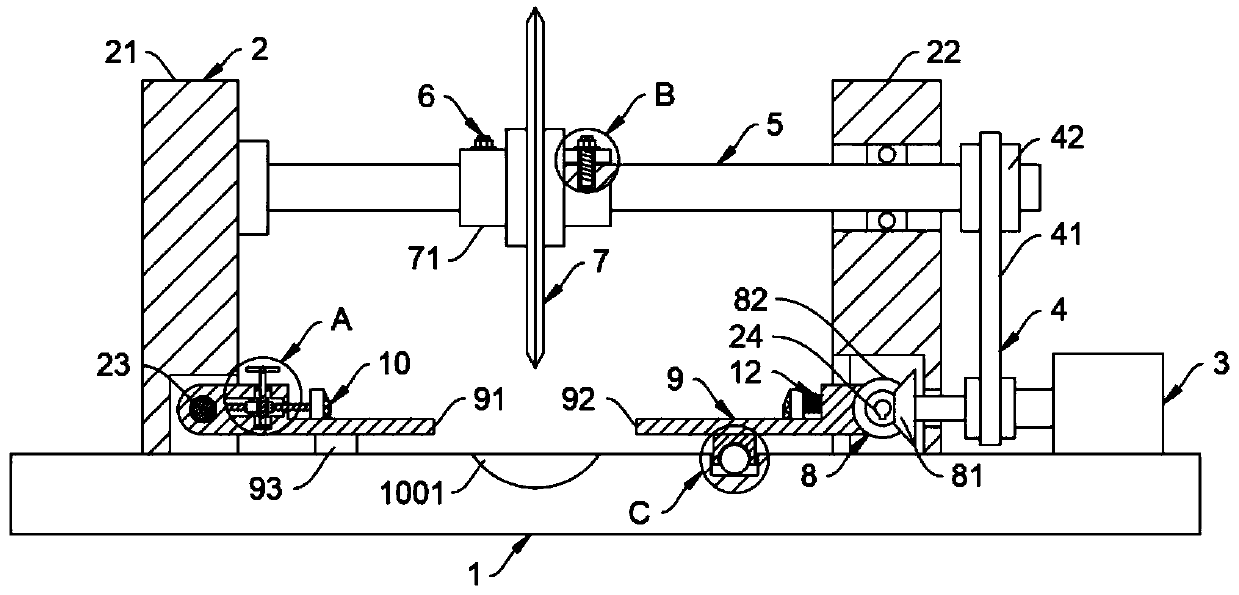

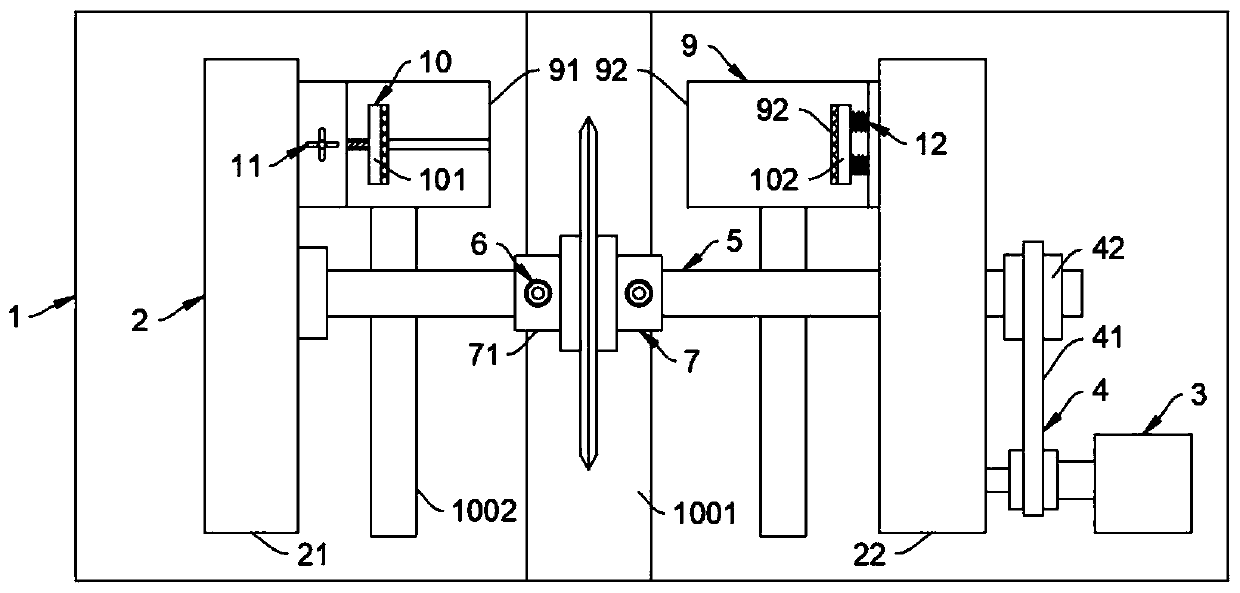

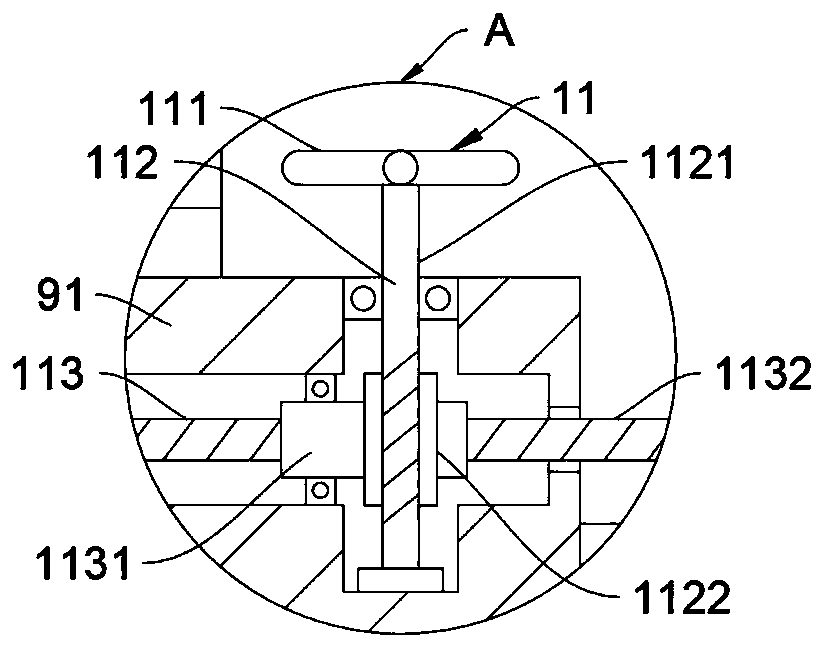

[0032] Such as Figure 1-5 As shown, a wood cutting device for furniture production and processing includes a workbench 1, and the workbench 1 is symmetrically provided with a column 2, and the workbench 1 is fixedly connected with a drive motor 3. It should be noted that the column 2 includes a left column 21 and a The right column 22 is used for the supporting work of the cutting wheel 7 in the device and the flexible connection to the moving device 9 .

[0033] Further, the driving motor 3 adopts a stepping driving motor whose model is HB860.

[0034] Further, the drive motor 3 is rotatably connected with the support shaft 5 through the transmission mechanism 4. It should be noted that the transmission mechanism 4 includes a belt 41 and two pulleys 42, wherein one pulley 42 is fixedly connected to the output shaft of the drive motor 3, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com