Prefabricated component transporting and mounting equipment for fabricated building construction

A technology for building construction and prefabricated components, applied in the directions of transportation and packaging, internal accessories, bottle/can components, etc., can solve the problem of inability to effectively ensure the stable transportation of the slope protection components of the Hexagon Reservoir, achieve convenient up and down movement, and improve safety. performance, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

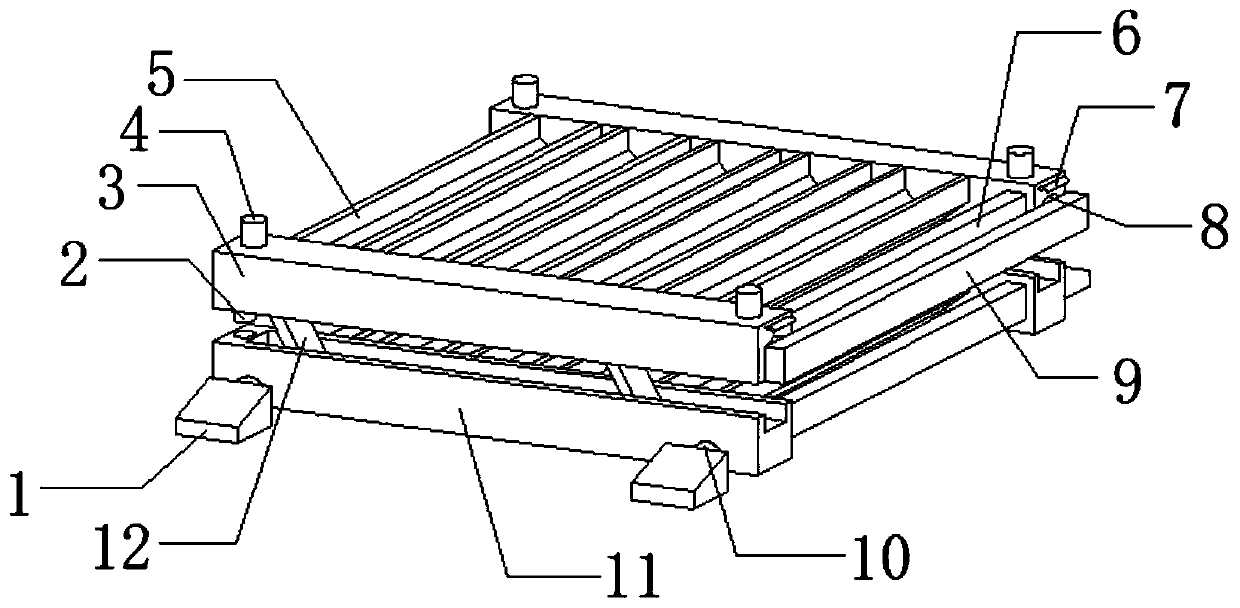

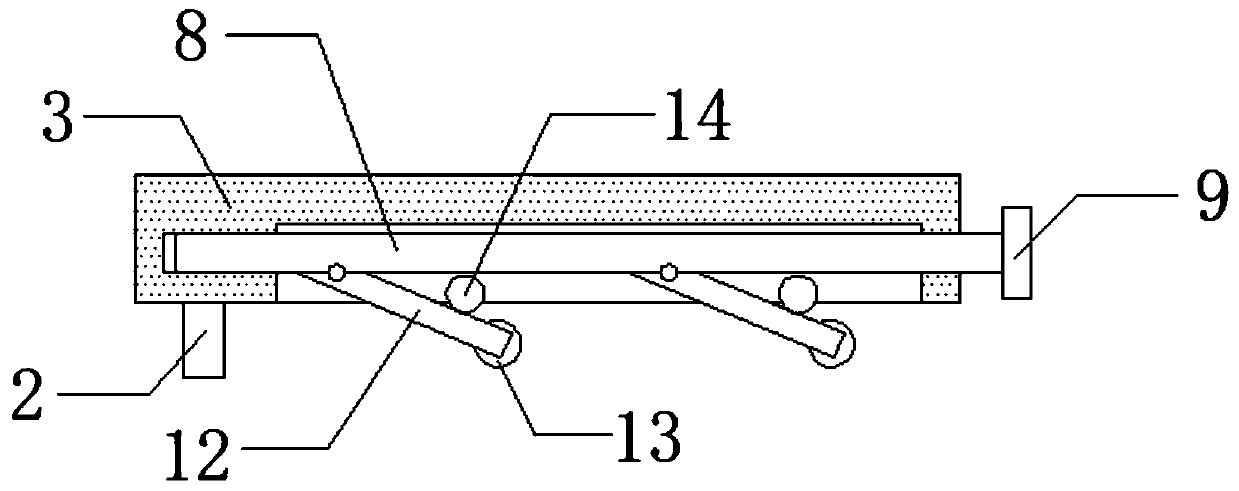

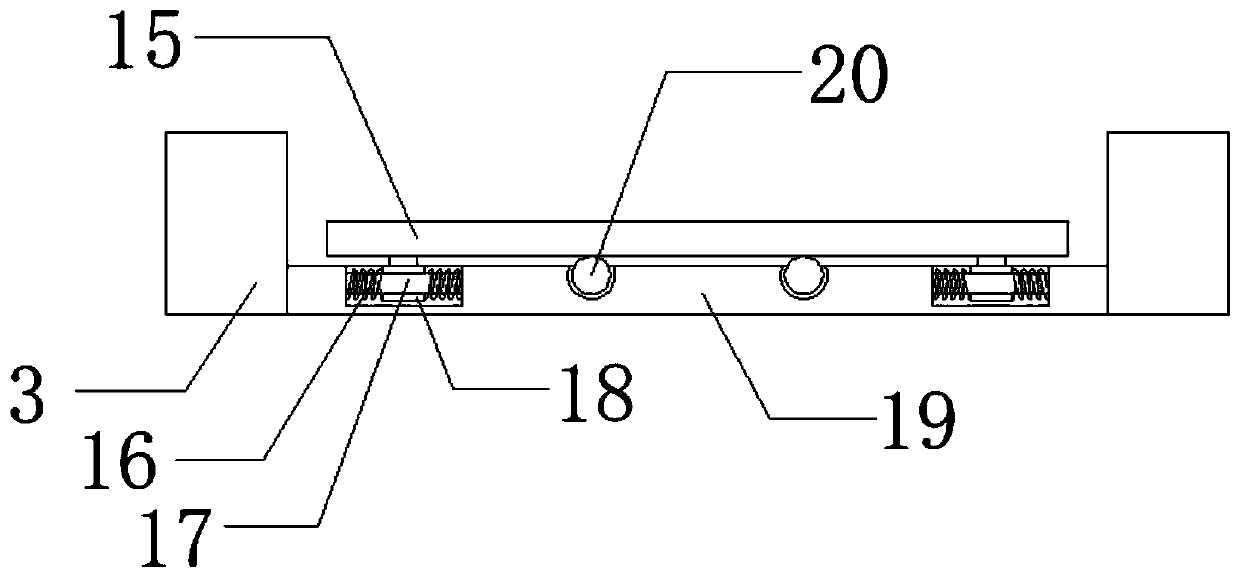

[0033] refer to Figure 1-6 , a prefabricated component transportation and installation equipment for prefabricated building construction, comprising two first support plates 3 and two second support plates 11, two sides of adjacent ends of the two first support plates 3 and two second support plates The outer walls on both sides of the adjacent ends of the two supporting plates 11 are connected with the first connecting plates 6 by bolts, and the supporting base plates 19 are connected by bolts between the two first supporting plates 3 and between the two second supporting plates 11. The outer walls at both ends of the top of the support base plate 19 are provided with first grooves arranged equidistantly, and the inner walls at both ends of the first groove are connected with the same sliding guide rail 17 by bolts, and the peripheral outer walls of the sliding guide rail 17 are slidingly sleeved with sliding sleeves. block 18, and the outer walls at both ends of the sliding...

Embodiment 2

[0045] refer to Figure 1-7 , a prefabricated component transportation and installation equipment used for prefabricated building construction, also includes limit pressure plates 33 installed on the inner walls of both sides of the limit opening 31 through hinges, and the outer walls of the adjacent sides of the two limit pressure plates 33 are equally spaced A third protrusion 34 is provided, and a third spring 32 is connected between the outer walls of the two position-limiting pressure plates 33 on one side away from each other and the inner walls of both sides of the position-limiting opening 31 through bolts.

[0046] During use, the top cover 28 is pressed on the hexagonal reservoir slope protection member on the first support plate 3, and when the hexagonal reservoir slope protection member is pressed on the top of the adjacent side of the limit pressing plate 33, the hexagonal reservoir slope protection member will follow the limit The pressure plate 33 moves upwards....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com