Intelligent garbage classification device and method

A garbage classification and garbage technology, which is applied in the directions of trash cans, garbage collection, waste collection and transfer, etc., can solve problems such as difficulty in sorting work, and achieve the effect of high degree of automation, wide application prospects, and improved recognition ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

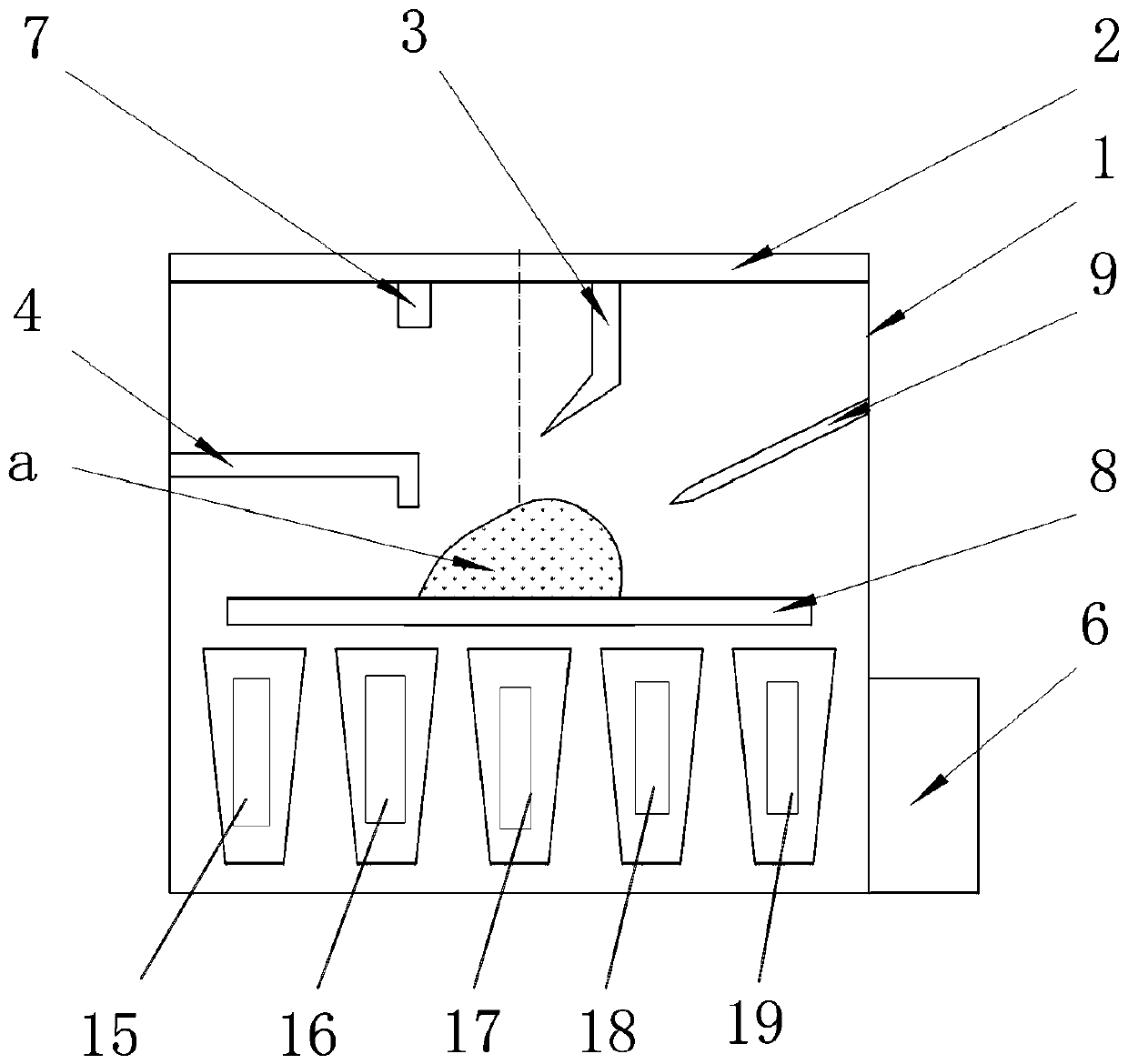

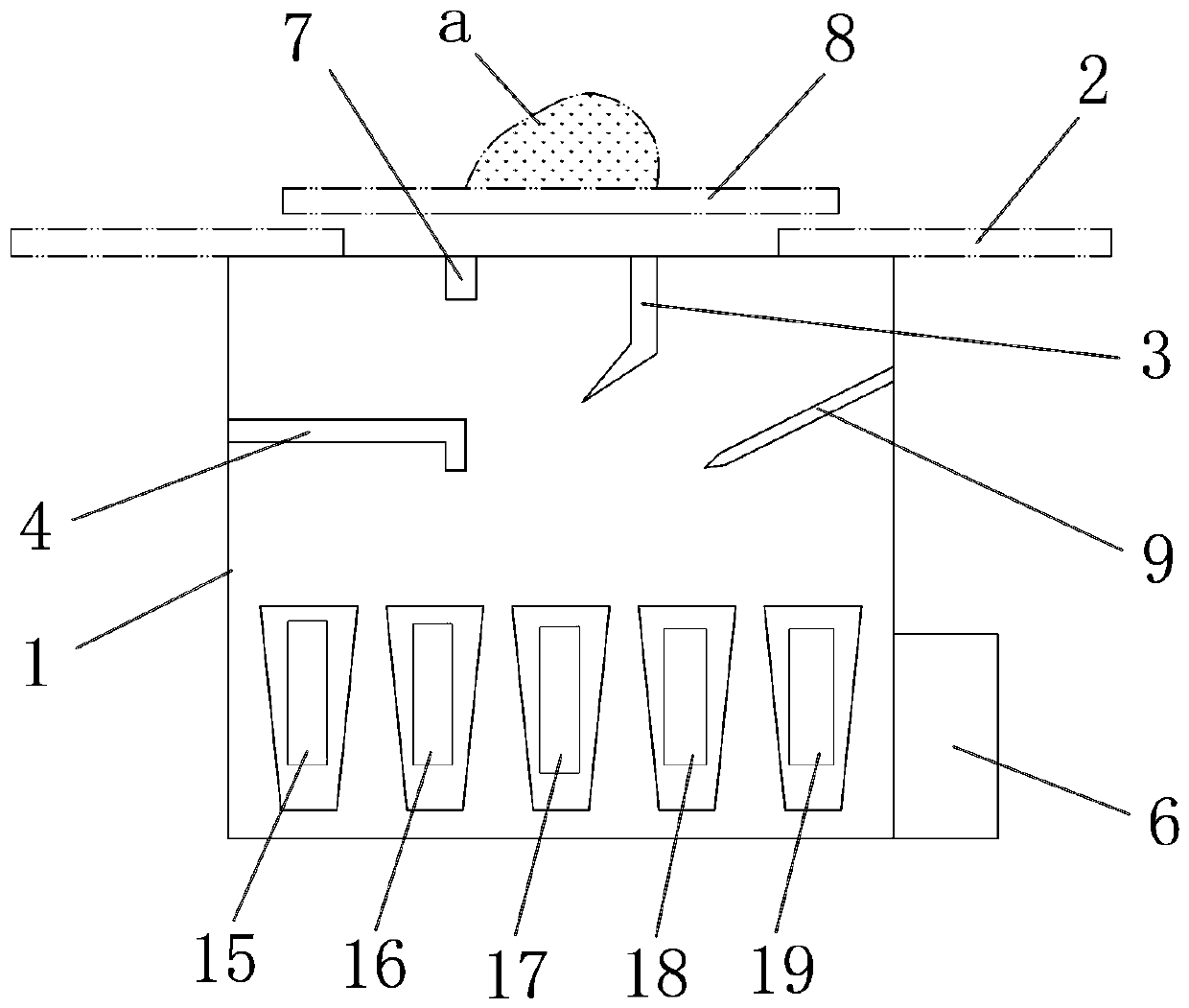

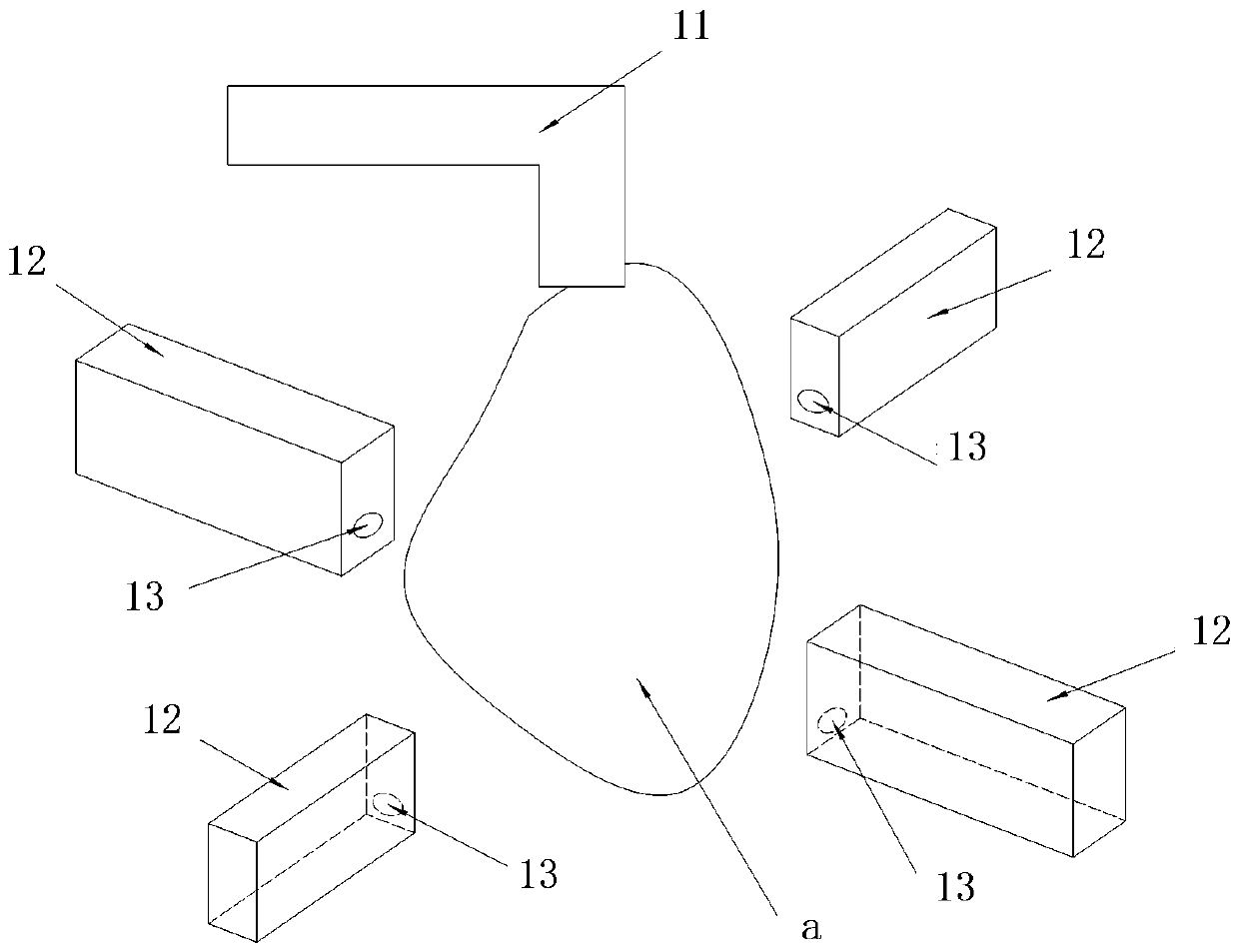

[0024] Such as Figure 1-3 As shown, an intelligent garbage sorting device includes a housing assembly 1, a door assembly 2, a bag breaking assembly 3, a manipulator assembly 4, a measuring assembly and a control assembly 6, the top of the housing assembly 1 is open, and the door assembly 2 includes two side-by-side doors. The measurement assembly includes a scanning identification assembly 7, a weighing assembly 8 and an in-bag detection assembly 9. The scanning identification assembly 7 is arranged on the upper part of the shell assembly 1, and the weighing assembly The heavy component 8 is arranged in the shell component 1 through the lifting mechanism and can extend through the top opening of the shell component 1. The detection component 9 in the bag includes a temperature sensor, a humidity sensor and a metal detector. The broken bag component 3 It includes a carrying bag component 11, an optical ranging component 12, and a laser cutting component 13. The optical ranging...

Embodiment 2

[0026] A kind of garbage sorting method, utilizes the intelligent garbage sorting device described in embodiment 1, such as Figure 1-3 shown, including the following steps:

[0027] Start the equipment, the two side-by-side doors of the door assembly 2 are opened, and the lifting mechanism extends the weighing assembly 8 out of the shell assembly 1, and places the bagged garbage a on the weighing assembly 8;

[0028] The lifting mechanism lowers the weighing assembly 8 back into the shell assembly 1, and the side-opening door is closed;

[0029] The weighing component 8 weighs the bagged garbage a, the scanning identification component 7 scans the shape of the bagged garbage a to measure the volume, and the in-bag detection component 9 is inserted into the bagged garbage a to measure the internal temperature, humidity and metal detection ;

[0030] The bag-breaking component 3 performs bag-breaking operation on the bagged garbage a to disperse the garbage;

[0031] The sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com