Macromolecular polysaccharide hydrogel and preparation method thereof

A hydrogel and polymer technology, applied in chemical instruments and methods, water pollutants, pharmaceutical formulations, etc., can solve the problem of poor hemostatic efficacy, achieve good growth, simple method, and accelerated hemostasis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

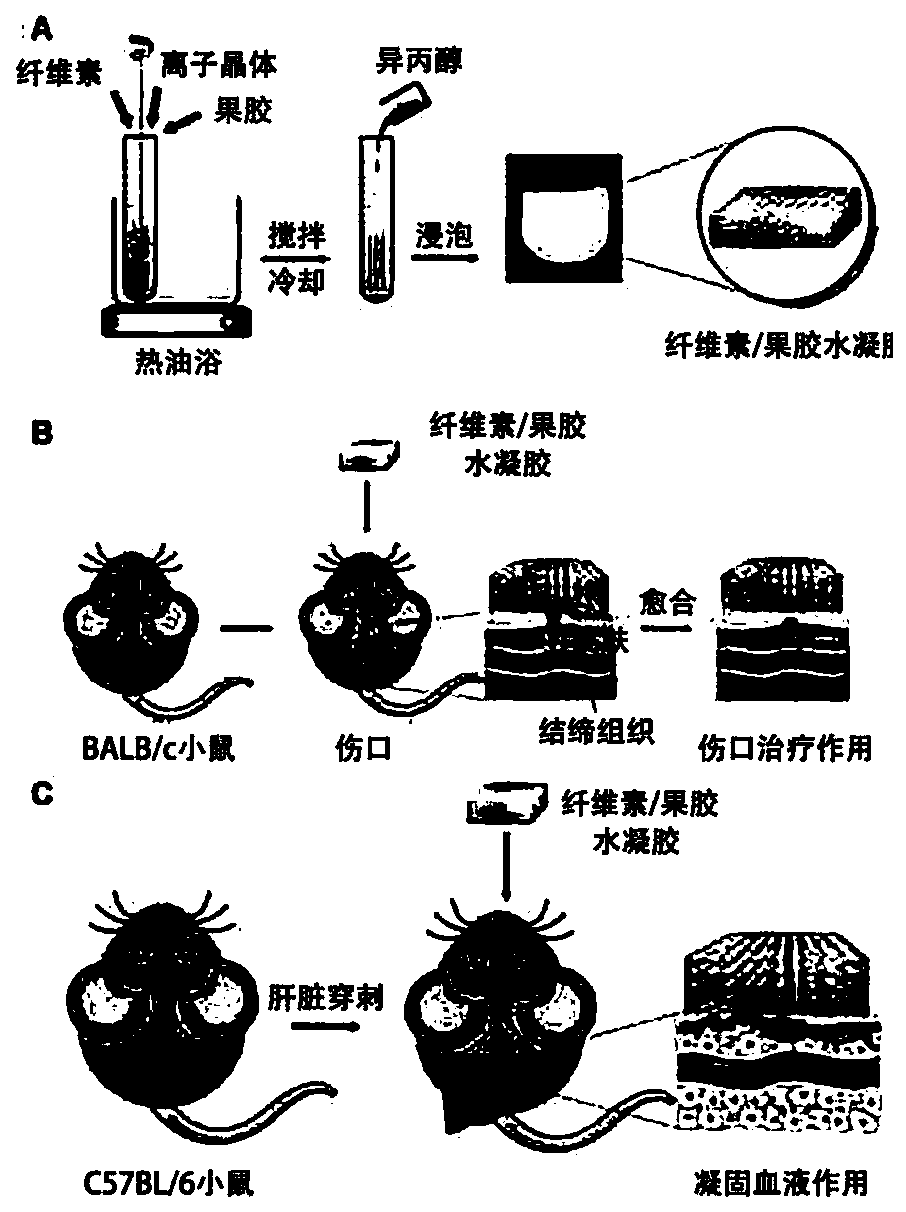

[0039] A preparation method of a drug-adsorbable polymer polysaccharide hydrogel, comprising the following steps:

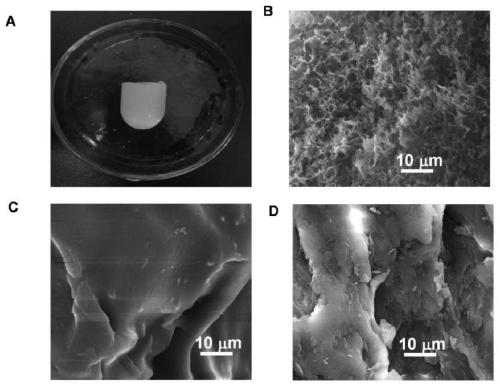

[0040] Take 0.50 g of pineapple pomace cellulose (PC) and 0.40 g of pectin in a test tube, then add 10 g of [AMIm]Cl, place the test tube in a constant temperature magnetic stirring oil bath, stir and dissolve at 100 ° C, and set the speed to 60 rev / min. After heating, cool to room temperature. Then add isopropanol-water (1:1) solution into the tube and soak until the colloid is precipitated. To fully wash the ionic liquid, the isopropanol-water solution in the test tube was replaced several times during the soaking period. Finally, the colloid is fully soaked and washed with deionized water, and freeze-dried at -80°C to obtain the pineapple pomace cellulose-pectin composite hydrogel (such as figure 1 and figure 2 shown).

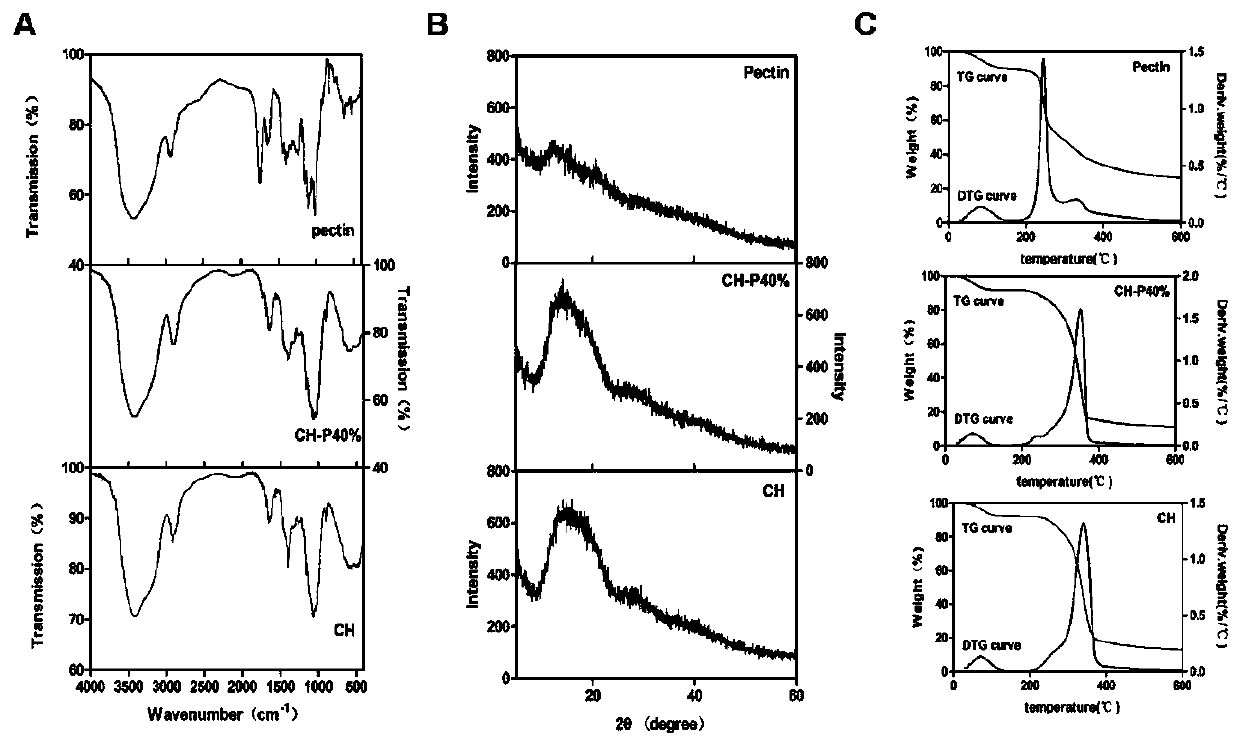

[0041] The properties of the hydrogel prepared by the method of the present invention were measured as follows.

[0042] (1) Morpholog...

Embodiment 2

[0055] A preparation method of a drug-adsorbable polymer polysaccharide hydrogel, comprising the following steps:

[0056] Take 0.50 g of bagasse cellulose (SC) and 0.30 g of pectin in a test tube, then add 10 g of [Bdmim]Cl, place the test tube in a constant temperature magnetic stirring oil bath, stir and dissolve at 100 ° C, and set the speed to 50 rev / min. After heating, cool to room temperature. Then add isopropanol-water (1:1) solution into the tube and soak until the colloid is precipitated. To fully wash the ionic liquid, the isopropanol-water solution in the test tube was replaced several times during the soaking period. Finally, the colloid was fully soaked and washed with deionized water, and freeze-dried at -80°C to obtain a bagasse cellulose-pectin composite hydrogel. As in the above experiment, the hydrogel in this experiment has excellent biocompatibility, drug adsorption and drug sustained release properties.

Embodiment 3

[0058] A preparation method of a drug-absorbing polymer polysaccharide hydrogel, such as figure 1 The following steps are shown:

[0059] Take 0.50g of tea cellulose (TC) and 0.10g of pectin in a test tube, then add 10g of [bmim]Cl, place the test tube in a constant temperature magnetic stirring oil bath, stir and dissolve at 100°C, and set the speed to 60 turn / min. After heating, cool to room temperature. Then add isopropanol-water (1:1) solution into the tube and soak until the colloid is precipitated. To fully wash the ionic liquid, the isopropanol-water solution in the test tube was replaced several times during the soaking period. Finally, the colloid was fully soaked and washed with deionized water, and freeze-dried at -80°C to obtain the tea cellulose-pectin composite hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap