Environment-friendly rubber asphalt, asphalt mixture and its preparation method and application

An environmentally friendly rubber and asphalt technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of high harmful gas emissions, serious environmental pollution, and strong odor, and achieve low odor concentration, environmental protection, and odor small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. The production process of environment-friendly rubber asphalt is to heat 78.35% asphalt to 190°C in a reaction kettle, add 0.15% catalyst and stir for 10 minutes, 1.5% stearyl alcohol for 20 minutes, and 20% rubber powder for 90 minutes. Environment-friendly rubber asphalt can be prepared.

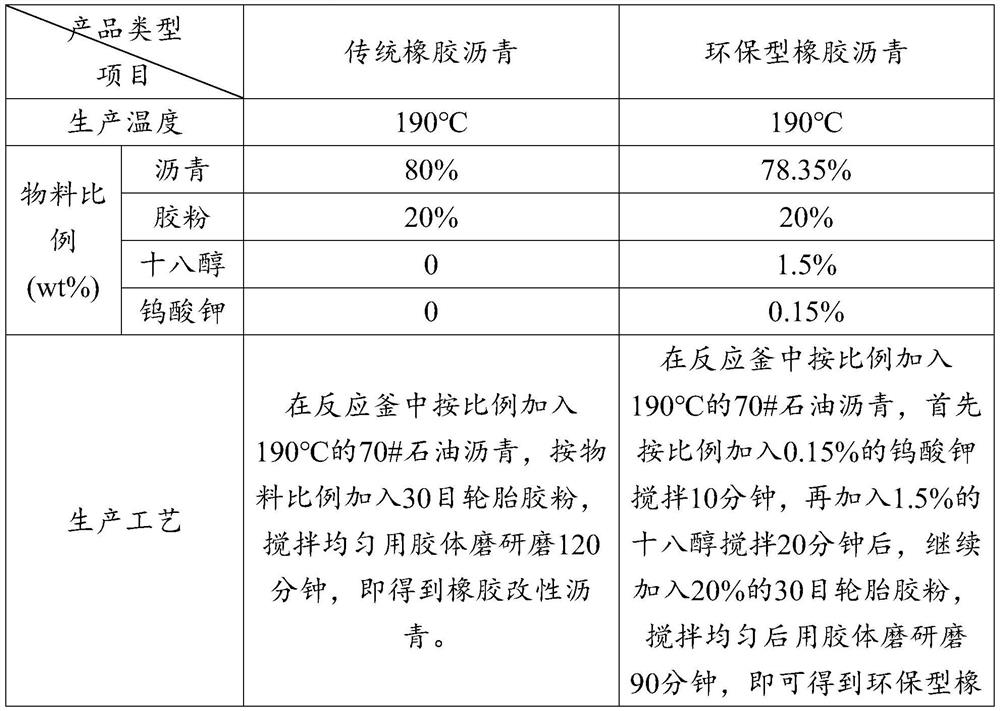

[0038] 2. See Table 1 for the comparison of the preparation process and materials between the environment-friendly rubber asphalt in this example and the traditional rubber asphalt.

[0039] Table 1 Comparison of rubber asphalt preparation process and materials with different processes

[0040]

[0041]

[0042] 3. Collection and detection of flue gas from rubber asphalt production

[0043] During the production of rubber-modified asphalt with the above different processes, rubber powder was added and ground for 100 minutes, and the flue gas was collected in the reactor for gas composition analysis. The data are shown in Table 2.

[0044] Table 2 Analysis and comparison o...

Embodiment 2

[0061] 1. The production process of environment-friendly rubber asphalt is to heat 77.8% asphalt to 190°C in the reaction kettle, add 0.2% catalyst and stir for 10 minutes, 2.0% stearyl alcohol for 20 minutes, and 20% rubber powder for 90 minutes. Environment-friendly rubber asphalt can be obtained.

[0062] 2. The comparison of environment-friendly rubber asphalt and traditional rubber asphalt preparation process and process materials is shown in Table 6.

[0063] Table 6 Preparation process and material comparison of rubber asphalt with different processes

[0064]

[0065] 3. Collection and detection of exhaust gas from rubber asphalt production

[0066] During the production of rubber-modified asphalt with the above different processes, rubber powder was added and ground for 100 minutes, and the flue gas was collected in the reactor for gas composition analysis. The data are shown in Table 7.

[0067] Table 7 Analysis and comparison of harmful gases in the tail gas of...

Embodiment 3

[0079] 1. The production process of environment-friendly rubber asphalt is to heat 76.7% asphalt to 190°C in a reaction kettle, add 0.3% catalyst and stir for 10 minutes, 3.0% stearyl alcohol for 20 minutes, and 20% rubber powder for 90 minutes. Environment-friendly rubber asphalt can be obtained.

[0080] 2. See Table 9 for the comparison of environment-friendly rubber asphalt and traditional rubber asphalt preparation process and process materials.

[0081] Table 9 Preparation process and material comparison of rubber asphalt with different processes

[0082]

[0083] 3. Collection and detection of exhaust gas from rubber asphalt production

[0084] During the production of rubber-modified asphalt with the above different processes, rubber powder was added and ground for 100 minutes, and the flue gas was collected in the reactor for gas composition analysis. The data are shown in Table 10.

[0085] Table 10 Analysis and comparison of harmful gases in the tail gas produc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap