Saline-alkali soil improver and method for preparing saline-alkali soil improver by using phosphate rock tailings and low-rank coal

A technology for phosphate rock tailings and saline-alkali soil, applied in the chemical industry, can solve problems such as difficulty in promotion, untargeted addition of microorganisms, soil compaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Raw material: phosphate rock tailings, collection location: Sinochem Yunlong Co., Ltd.

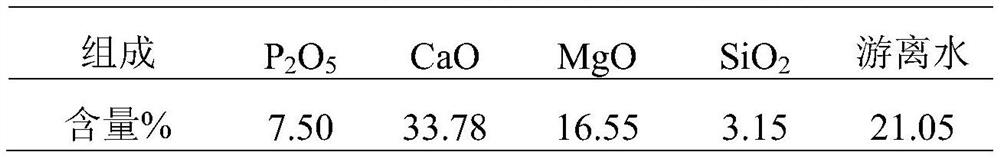

[0051] The chemical composition of the phosphorite tailings in the present embodiment is shown in the following table 1;

[0052]Table 1 Chemical composition of phosphate rock tailings

[0053]

[0054] Raw material: lignite, collection location: Yunnan Gold Institute

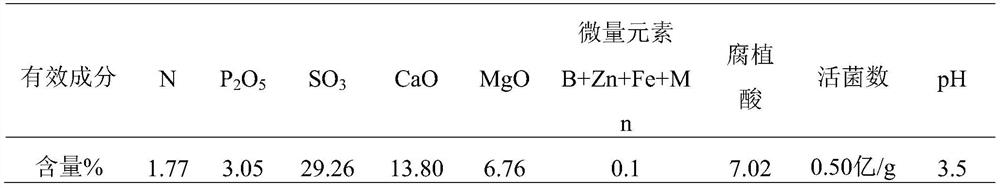

[0055] The chemical composition of the present embodiment lignite is shown in the following table 2;

[0056] Table 2 Chemical composition of lignite

[0057]

[0058] Raw materials: 98% sulfuric acid, purchased from the market

[0059] Raw materials: 60% nitric acid, purchased from the market

[0060] Raw materials: trace elements, boric acid (purity 99%), zinc oxide (purity 99%), ferrous oxide (purity 99%), manganese dioxide (purity 60%), purchased from the market

[0061] Raw materials: Bacillus subtilis 200 billion / g, Bacillus megaterium 100 billion / g and Aspergillus niger 10 billion / g, purchased from ...

Embodiment 2

[0069] Raw material: phosphate rock tailings, same as embodiment 1

[0070] Raw material: lignite, with embodiment 1

[0071] Raw material: sulfuric acid, with embodiment 1

[0072] Raw material: 40wt% nitric acid, market purchase

[0073] Raw material: trace element, with embodiment 1

[0074] Raw materials: bacteria agent Bacillus megaterium 100 billion / g and Aspergillus niger 10 billion / g, purchased from the market

[0075] Preparation:

[0076] Phosphate tailings and sulfuric acid (with 98% H 2 SO 4 ) and water in a mass ratio of 1:1.1:0.4, and reacted and matured in a closed curing silo at a curing temperature of 90°C for 3 days to obtain a powdery material; the lignite was wet-milled to 20 mesh , the water content of the coal slurry is 80%, lignite slurry (on a dry basis) and nitric acid (40% HNO 3 According to the mass ratio of 1:0.5, the oxidative nitration reaction is carried out in a closed reaction kettle, the reaction temperature is 90 ° C, the reaction time...

Embodiment 3

[0082] Raw material: phosphate rock tailings, same as embodiment 1

[0083] Raw material: lignite, with embodiment 1

[0084] Raw material: sulfuric acid, with embodiment 1

[0085] Raw material: 70wt% nitric acid, market purchase

[0086] Raw materials: trace elements, zinc sulfate (purity 99%), boric acid (purity 99%)

[0087] Raw materials: bacteria agent Bacillus amyloliquefaciens 100 billion / g, Bacillus megaterium 100 billion / g, purchased from the market

[0088] Preparation:

[0089] Phosphate tailings and sulfuric acid (with 98% H 2 SO 4 ) and water in a mass ratio of 1:0.5:0.1, and reacted and matured in a closed curing silo at a temperature of 30°C and a curing time of 30 days to obtain a powdery material; the lignite was wet-milled to 100 mesh , the water content of coal slurry is 30%, lignite slurry (on dry basis) and nitric acid (70% HNO 3 According to the mass ratio of 1:0.7, the oxidative nitration reaction is carried out in a closed reaction kettle, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com