Copper-based self-lubricating composite material which can be used at room temperature to 500 DEG C, and preparation method and application thereof

A composite material and self-lubricating technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of insufficient material strength and lubricity, achieve high strength, improve wear-resistant lubrication performance, and enhance matrix strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

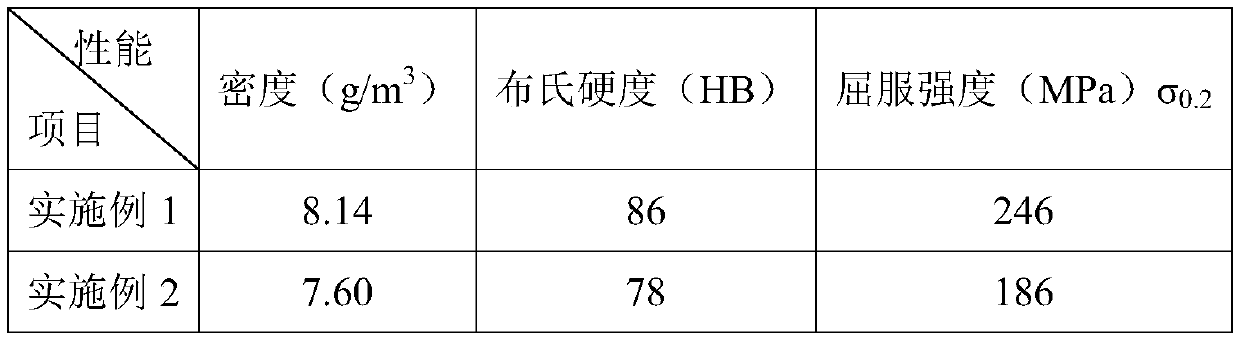

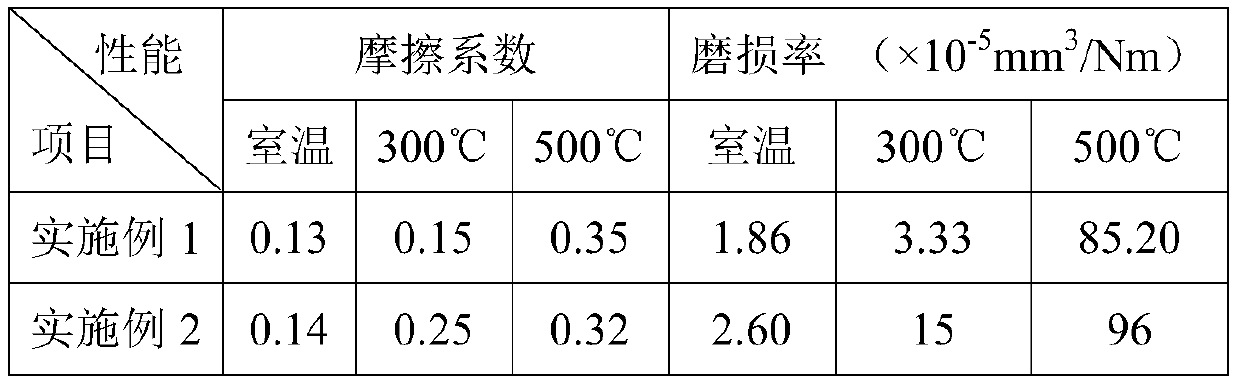

Embodiment 1

[0034] The copper-based self-lubricating composite material of the present embodiment consists of the following components in weight percentage: Ni 9%, Sn 5%, Si 0.1%, Al 0.1%, Graphene 0.8%, LaF 3 0.08%, the balance is Cu. Among them, Cu, Sn, Ni, and Al are all electrolytic powders, Cu, Sn, Ni, Al, Si, graphene and LaF 3 The purity is greater than 99.5%, the particle size of Cu, Sn, Ni, Al, Si is less than 0.06mm, graphene and LaF3 The particle size is less than 0.035mm.

Embodiment 2

[0036] The copper-based self-lubricating composite material of the present embodiment consists of the following components in weight percentage: Ni 12%, Sn 5%, Si 0.3%, Al 0.5%, graphene 1.5%, LaF 3 0.5%, the balance is Cu. Among them, Cu, Sn, Ni, and Al are all electrolytic powders, Cu, Sn, Ni, Al, Si, graphene and LaF 3 The purity is greater than 99.5%, the particle size of Cu, Sn, Ni, Al, Si is less than 0.06mm, graphene and LaF 3 The particle size is less than 0.035mm.

Embodiment 3

[0038] The copper-based self-lubricating composite material of the present embodiment is composed of the following components in weight percentage: Ni 4%, Sn6%, Si 0.5%, Al 0.05%, graphene 2%, LaF 3 0.05%, the balance is Cu. Among them, Cu, Sn, Ni and Al are reduced powders, Cu, Sn, Ni, Al, Si, graphene and LaF 3 The purity is greater than 99.5%, the particle size of Cu, Sn, Ni, Al, Si is less than 0.06mm, graphene and LaF 3 The particle size is less than 0.035mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com