Steam condensed water system

A technology of steam condensing water and steam, which is applied in the field of papermaking, which can solve the problems of high steam consumption per ton of paper and low drying efficiency, and achieve the effects of improving heat energy use efficiency, improving drying efficiency, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

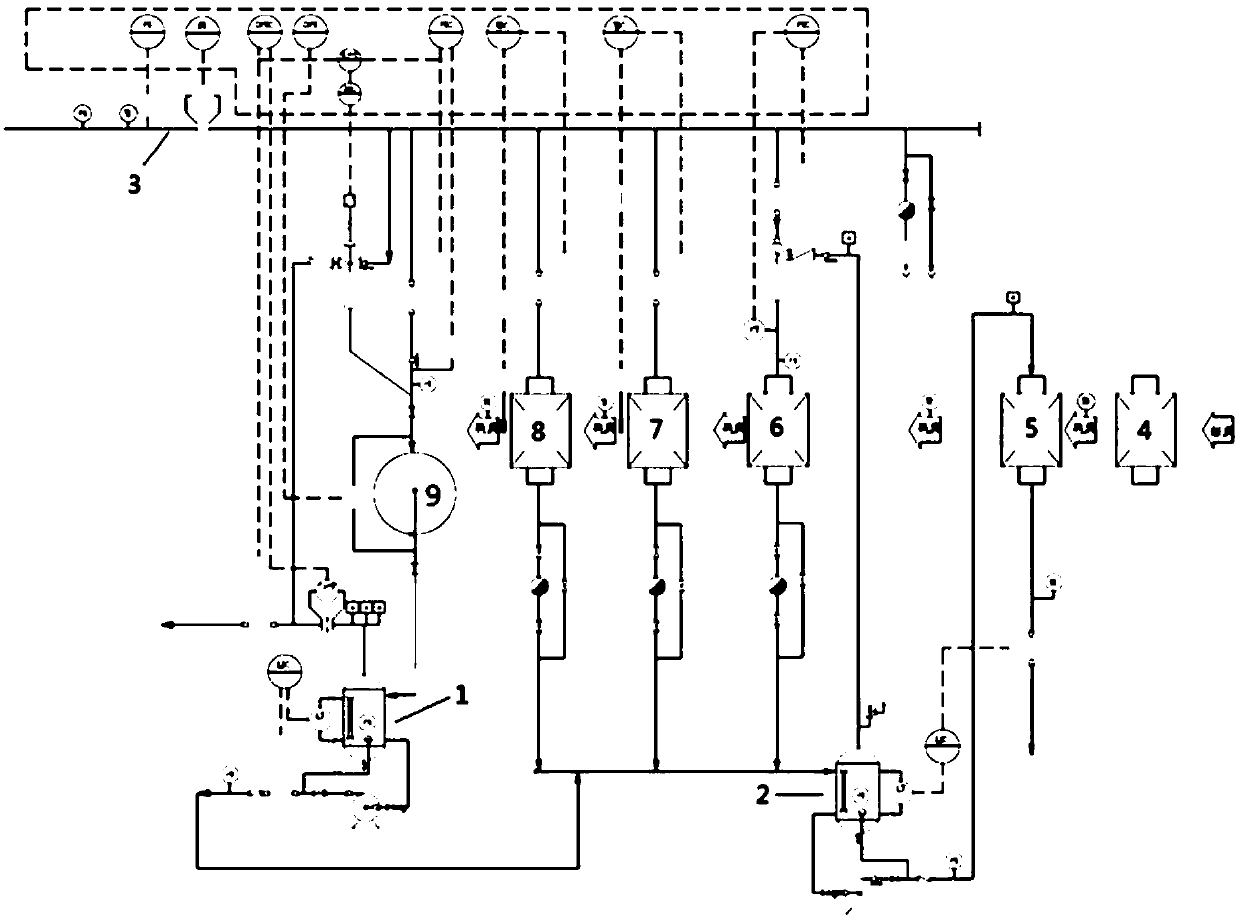

[0024] A steam condensate system, its structure is as figure 1 As shown, including the flash tank and heat exchange components, there are two sets of flash tanks, the first group of flash tanks 1 is connected to the drying cylinder 9 and the high-pressure steam pipeline 3, and the dry steam introduced is 12bar high-pressure steam, and the operating pressure range is Between 1bar and 5bar. The second group of flash tanks 2 is connected with the heat exchange components, and the heat exchange components used include air-gas converter 4, dry-end condensate heat exchanger 5, dry-end flash steam heat exchanger 6, dry-end steam heat exchanger 7, the wet end steam heat exchanger 8, the gas-gas converter 4 communicates with the dry end condensate heat exchanger 5, the dry end condensate heat exchanger 5 communicates with the second flash tank 2, and the dry end flash steam heat The exchanger 6 , the dry-end steam heat exchanger 7 , and the wet-end steam heat exchanger 8 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com