Control system and method for continuously walking and automatically positioning tamping area

An automatic positioning and control system technology, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as operational errors, inaccurate positioning of tamping areas, cumbersome manual operations, etc., to promote correct transformation, The effect of reducing the number of vehicle positioning adjustments and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

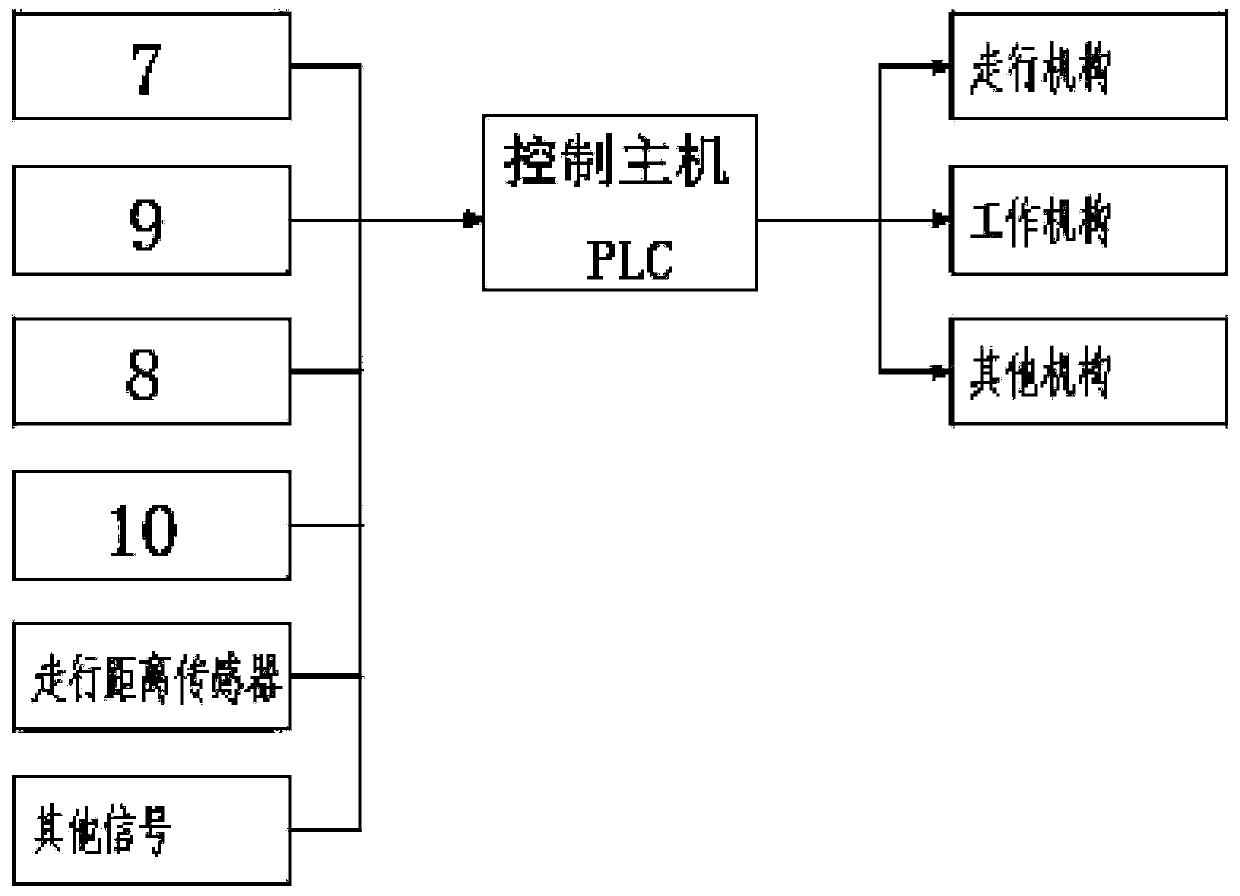

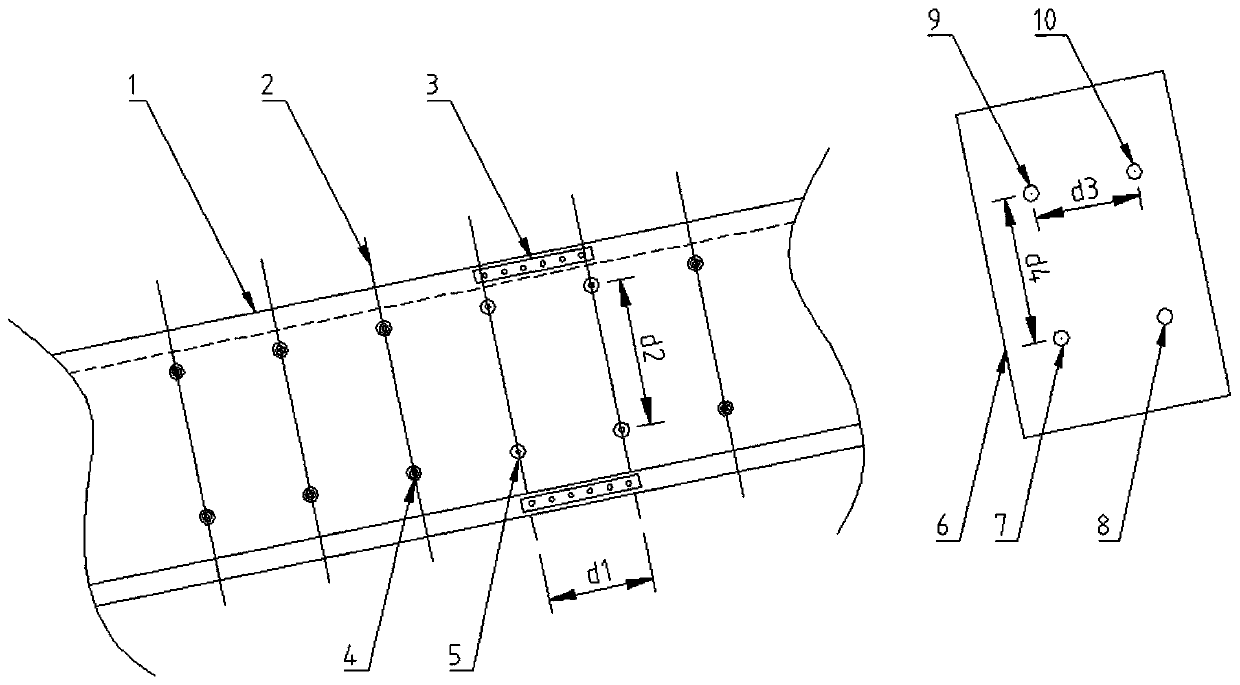

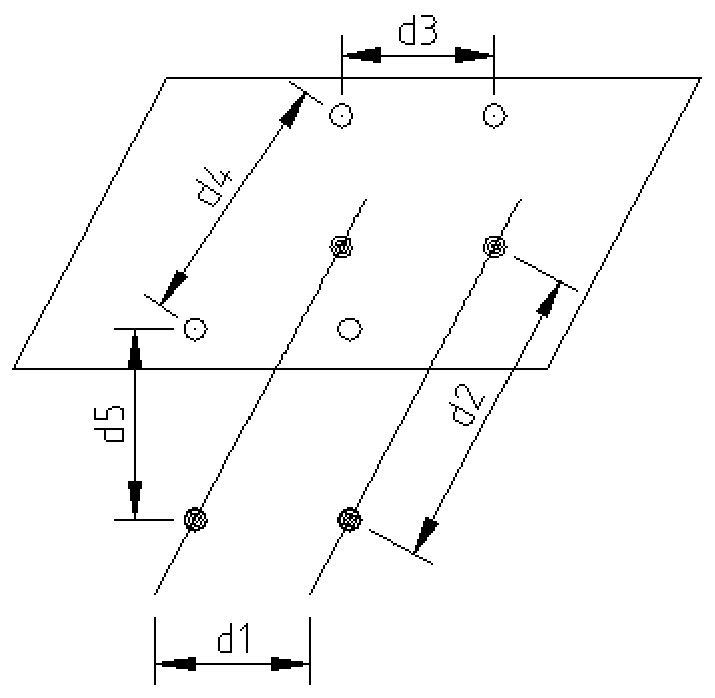

[0043] Combine below Figure 1-3 Describe in detail the preferred technical scheme of the control system for the continuous walking and automatic positioning of the tamping area:

[0044] A control system for continuously walking and automatically positioning a tamping area, including a control host PLC for processing data, a tag for transmitting signals, a receiver for receiving signals from the tags, and a travel distance for verification of travel distance The sensor, the tags include a first tag 4 and a second tag 5, the first tag 4 is set on the sleeper 2 at the non-connecting plate 3 on the track 1, and the second tag 5 is set on the sleeper at the connecting plate 3 on the track 1 2, the control host PLC, receiver and travel distance sensor are installed on the body 6 of the tamping vehicle.

[0045] Both the first tag 4 and the second tag 5 use RFID electronic tags or signal transmitters, and the receivers both use RFID receivers.

[0046] The receivers include a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com